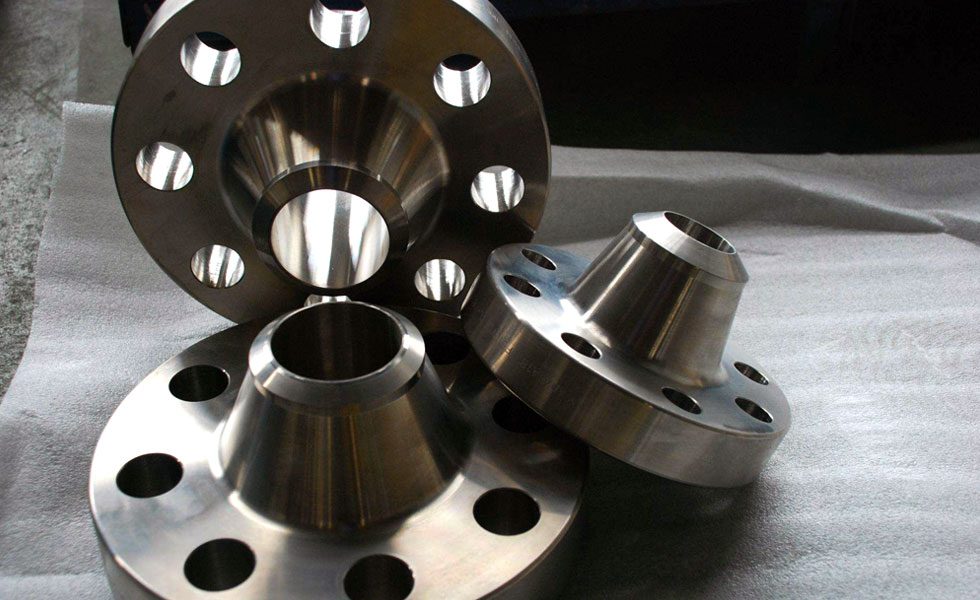

UNI Weld Neck Flanges PN6 to PN40

Manufacturer and Supplier of UNI Weld Neck Flanges PN6 to PN40 in Various Material Grades

UNI PN6 Weld Neck Flanges Manufacturer in Mumbai, India. Carbon Steel UNI PN40 Weld Neck Flanges Supplier, Stainless Steel UNI PN6 Weld Neck Flanges Exporter, Alloy Steel UNI PN25 Weld Neck Flanges Stockist, Copper Nickel UNI PN10 Weld Neck Flanges Distributor, Inconel UNI PN16 Weld Neck Flanges, Monel UNI PN40 Weld Neck Flanges, Hastelloy UNI PN6 Weld Neck Flanges, Duplex Steel UNI PN6 to PN40 Weld Neck Flanges Manufacturer & Exporter in Mumbai, India.

We supply a wide range of high-quality UNI Weld Neck Flanges in pressure ratings PN6 to PN40, manufactured to meet stringent dimensional accuracy and mechanical strength standards. These flanges are widely used in critical applications such as waterworks, chemical processing, oil & gas, HVAC systems, and general industrial piping, ensuring leak-proof joints and reliable performance under pressure. All products are produced in compliance with global quality norms and can be customized to meet your specific project needs.

Werner Flanges Inc. is a trusted manufacturer and exporter of premium-quality UNI Weld Neck Flanges PN6 to PN40, designed for high-integrity piping systems across various industries. Engineered to the specifications of the Italian UNI standard, these flanges are ideal for applications requiring excellent pressure resistance, leak-proof performance, and long service life. Available in pressure ratings from PN6 to PN40, our weld neck flanges are precisely machined with a long tapered hub to ensure seamless alignment with pipe systems. Whether you’re operating in oil & gas, water treatment, HVAC, chemical processing, or power generation, Werner Flanges Inc. delivers reliable flange solutions that meet global quality standards.

Manufactured from durable materials such as carbon steel, stainless steel, duplex steel, alloy steel, Inconel, Monel, and Hastelloy, our UNI weld neck flanges provide exceptional strength and corrosion resistance under demanding conditions. With a strong focus on dimensional accuracy, finish, and certified testing, we ensure every flange we produce exceeds customer expectations. To request a quote, place an order, or speak with our technical team, email us today at sales@wernerflanges.com. Werner Flanges Inc. — where quality meets precision in every weld neck flange we deliver.

Werner Flanges Inc. is one of the leading manufacturers and suppliers of UNI PN6 Weld Neck Flanges in a wide range of high-performance materials, including Duplex Steel, Carbon Steel, Stainless Steel 316, Inconel 601, Hastelloy C276, Monel K500, Copper Nickel, and Titanium. Our UNI Weld Neck Flanges are designed with a long tapered hub for superior stress distribution and strong, leak-proof welding connections—ideal for demanding industrial applications. We offer Industrial UNI PN6 Weld Neck Flanges, Flat Face and Raised Face WN Flanges, and custom-engineered variants to meet client-specific requirements. These flanges are widely used in water treatment plants, firefighting systems, and general low-pressure piping environments.

In addition to PN6, we manufacture and export a full range of UNI PN10, PN16, PN25, and PN40 Weld Neck Flanges designed to handle increased pressure requirements. Our portfolio includes Carbon Steel UNI PN40 Weld Neck Flanges, Duplex Steel UNI PN25 WN Flanges, Stainless Steel 316 UNI PN16 WN Flanges, Hastelloy UNI PN40 Weld Neck Flanges, and Titanium UNI PN10 Weld Neck Flanges, among others. Each flange is precisely machined for dimensional accuracy and tested to meet international quality standards.

UNI Weld Neck Flanges PN6 to PN40 Technical Specifications

| Specification | Details |

|---|---|

| Standard | UNI (Ente Nazionale Italiano di Unificazione) |

| Flange Type | Weld Neck Flanges (WN) |

| Pressure Ratings | PN6, PN10, PN16, PN25, PN40 |

| Size Range | DN 15 to DN 1200 (custom sizes available on request) |

| Facing Types | Raised Face (RF), Flat Face (FF) |

| Design Features | Long tapered hub for stress distribution and easy alignment with pipe, beveled end for butt welding |

| Applications | Oil & Gas, Water Treatment, Marine, HVAC, Power Generation, Chemical & Petrochemical Plants |

| Manufacturing Process | Forged and Machined according to UNI flange dimensional standards |

| Testing & Certification | EN 10204 3.1 / 3.2, Hydrostatic Test, Ultrasonic Test, PMI Test, Third-Party Inspection Available |

Material Specifications for UNI Weld Neck Flanges PN6 to PN40

| Type of Materials | Common Specifications / Customization Available on Request * Materials conform to ASTM/ASME standards and are compatible with UNI Weld Neck Flanges PN6 to PN40 |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347 |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Types of UNI Weld Neck Flanges PN6 to PN40

- UNI PN6 Weld Neck Flanges (WN)

- UNI PN10 Weld Neck Flanges (WN)

- UNI PN16 Weld Neck Flanges (WN)

- UNI PN25 Weld Neck Flanges (WN)

- UNI PN40 Weld Neck Flanges (WN)

- UNI PN6 Raised Face Weld Neck Flanges (RF WN)

- UNI PN10 Flat Face Weld Neck Flanges (FF WN)

- UNI PN16 Long Weld Neck Flanges

- UNI PN25 Forged Weld Neck Flanges

- UNI PN40 Heavy-Duty Weld Neck Flanges

Industries and Applications of UNI Weld Neck Flanges PN6 to PN40:

| Industry | Application |

|---|---|

| Oil & Gas Industry | Used in upstream, midstream, and downstream operations for high-pressure pipelines, separators, and manifolds requiring strong welded joints. |

| Water Treatment & Distribution | Installed in high-pressure water pipelines, filtration systems, and pumping stations for leak-proof and durable pipe connections. |

| Power Generation | Applied in thermal and hydro power plants for steam lines, heat exchangers, and critical high-temperature piping systems. |

| Chemical & Petrochemical Processing | Handles corrosive fluids and gases in reactors, heat exchangers, and chemical piping systems with high pressure and temperature conditions. |

| Marine & Offshore Engineering | Used in ballast systems, seawater cooling, and pressure piping on ships, rigs, and offshore platforms for corrosion resistance and strength. |

| HVAC & Building Services | Supports chilled water, heating loops, and pressurized air systems in large commercial and industrial facilities. |

| Mining & Mineral Processing | Suitable for slurry pipelines, processing tanks, and ore washing systems requiring robust, long-lasting weld neck connections. |

| Fire Protection Systems | Used in high-pressure fire suppression lines, hydrant systems, and sprinkler mains for secure, welded piping integrity. |

Frequently Asked Questions (FAQs) about UNI Weld Neck Flanges PN6 to PN40

- 1. What are UNI Weld Neck Flanges?

- UNI Weld Neck Flanges are flanges manufactured to UNI (Italian National Standards) that feature a long tapered hub for butt welding to a pipe, offering superior strength and resistance to dishing and distortion.

- 2. What pressure classes are available for UNI Weld Neck Flanges?

- UNI Weld Neck Flanges are available in PN6, PN10, PN16, PN25, and PN40 pressure ratings to suit various piping system requirements.

- 3. What materials are used for UNI Weld Neck Flanges?

- These flanges are typically manufactured from carbon steel, stainless steel (304/316), alloy steel, duplex steel, Inconel, Monel, Hastelloy, and copper nickel depending on the application.

- 4. What are the main applications of UNI Weld Neck Flanges?

- They are widely used in high-pressure and high-temperature piping systems in industries such as oil & gas, power plants, chemical processing, water treatment, and marine engineering.

- 5. What is the advantage of a weld neck flange over other types?

- The tapered hub of a weld neck flange ensures uniform distribution of stress and provides a strong, leak-proof connection ideal for critical service applications.

- 6. Are UNI Weld Neck Flanges interchangeable with DIN or EN standards?

- While similar in design, UNI flanges follow specific Italian dimensional standards. Compatibility should be checked with relevant specifications before substitution.

- 7. Where can I purchase certified UNI Weld Neck Flanges PN6 to PN40?

- You can buy certified UNI Weld Neck Flanges from trusted manufacturers like Werner Flanges Inc. For quotes or support, contact sales@wernerflanges.com.