SABS/SANS 1123 Table 2500/2 to 2500/8 Flanges

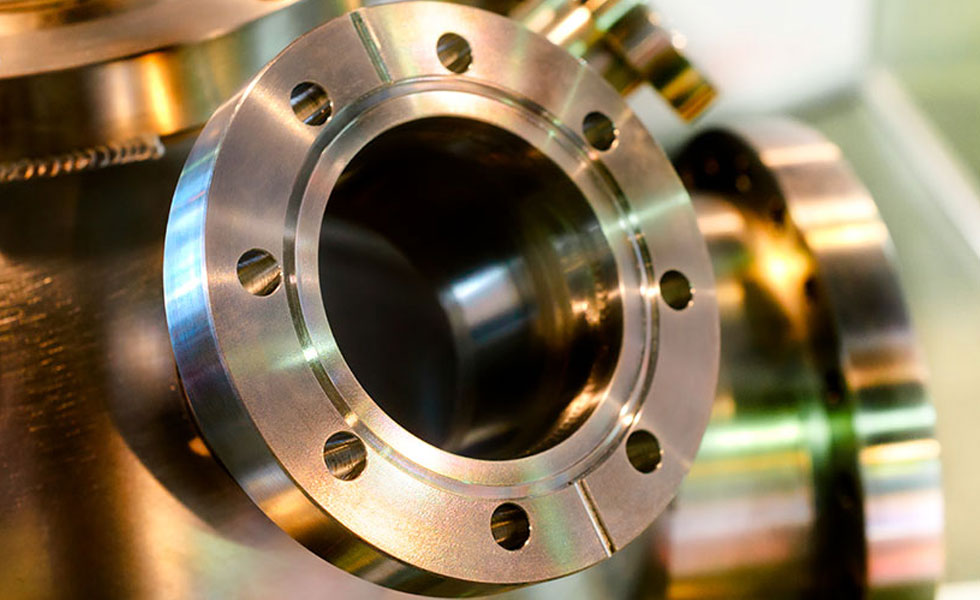

Manufacturer and Supplier of SABS/SANS 1123 Table 2500/2 to 2500/8 Flanges in Various Material Grades and Types. SABS/SANS 1123 Table 2500/2 to 2500/8 Flanges Manufacturer in Mumbai, India. We supply a complete range of SABS/SANS 1123 Table 2500/2 to Table 2500/8 Slip-On Flanges, Weld Neck Flanges, Blind Flanges, Threaded Flanges, and Lap Joint Flanges as per the South African Standard SANS 1123 specifications.

Carbon Steel SABS/SANS 1123 Table 2500/2 Slip-On Flanges Supplier, Stainless Steel Table 2500/3 Weld Neck Flanges Exporter, Alloy Steel Table 2500/4 Blind Flanges Stockist, Copper Nickel Table 2500/5 Threaded Flanges Distributor, Inconel Table 2500/6 Lap Joint Flanges Manufacturer, Monel SANS 1123 Table 2500 Flanges, Hastelloy Table 2500/7 Flanges, Titanium Table 2500/8 Flanges, and Duplex Steel SABS/SANS 1123 Table 2500/2 to 2500/8 Flanges Manufacturer & Exporter in Mumbai, India.

SABS/SANS 1123 Table 2500/2 to 2500/8 Flanges are precision-engineered components designed for high-pressure piping systems in accordance with the South African Bureau of Standards (SABS). These flanges are manufactured in various pressure classes from 2500/2 to 2500/8 and are ideal for applications requiring superior strength, leak-proof connections, and dimensional accuracy. Available in multiple face types like Raised Face (RF) and Flat Face (FF), these flanges come in Slip-On, Weld Neck, Blind, Threaded, and Lap Joint configurations. Each flange complies with SANS 1123 dimensional norms and is rigorously tested for pressure integrity and corrosion resistance.

Our SABS/SANS 1123 Table 2500 Flanges are offered in Carbon Steel, Stainless Steel (304/316), Duplex, Super Duplex, Copper Nickel, Monel, Inconel, and other exotic alloys. These flanges are widely used in oil & gas processing, petrochemical plants, power generation stations, and water treatment facilities where high-pressure and high-temperature performance is non-negotiable. As a trusted manufacturer and supplier based in Mumbai, India, we provide complete MTCs, 3.1/3.2 certifications, and third-party inspection reports to meet global quality compliance standards. For inquiries or bulk orders, contact: sales@wernerflanges.com

Stainless Steel 316 SABS/SANS 1123 Table 2500/2 Flanges, Carbon Steel SABS 1123 Table 2500/3 Slip-On Flanges, Duplex Steel S31803 SANS 1123 Table 2500/4 Weld Neck Flanges, Super Duplex S32750 SABS 1123 Table 2500/5 Blind Flanges, Titanium SABS/SANS 1123 Table 2500/6 Flanges, Copper Nickel SABS 1123 Table 2500/7 Threaded Flanges, CuNi SANS 1123 Table 2500/8 Lap Joint Flanges, Inconel SABS/SANS 1123 Table 2500/4 Weld Neck Flanges, Monel SABS 1123 Table 2500/2 Slip-On Flanges, SABS/SANS 1123 Table 2500 Flanges for High-Pressure Steam Systems, Nickel Alloy SABS/SANS 1123 Table 2500 Flanges for Chemical, Refining & Power Generation Plants, Carbon Steel SABS/SANS 1123 Table 2500/3 Flanges for Oil, Water & Gas Transmission Lines, SABS 1123 Table 2500 Flanges at Competitive Prices in India, SANS 1123 Table 2500 Flanges Ready Stock in Mumbai, India, SABS/SANS 1123 Table 2500 Flanges for Marine, Shipbuilding, Oil Rigs & Offshore Installations, SABS 1123 Table 2500/6 Flanges for High-Temperature, Corrosive, and Pressurized Media.

SABS/SANS 1123 Table 2500 Series Flanges Technical Specifications

| Standard | SABS/SANS 1123 Table 2500/2 to 2500/8 |

|---|---|

| Flange Types | Slip-On, Weld Neck, Blind, Threaded, Lap Joint, Spectacle Blind, Reducing |

| Pressure Rating | Up to 2500 kPa |

| Face Type | Raised Face (RF), Flat Face (FF) |

| Size Range | 15 NB to 1200 NB |

| Standards Compatibility | BS, ASTM, ISO, DIN (with dimensional compatibility) |

| Testing & Certification | EN 10204 3.1 / 3.2, TPI from BV, TUV, SGS, Lloyd’s |

Material Specifications for SABS/SANS 1123 Table 2500 Series Flanges

| Type of Materials | Common Specifications / Customization Available on Request * Materials conform to ASTM/ASME standards and are compatible with SABS/SANS 1123 Table 2500 Flanges |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347 |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Types of SABS/SANS 1123 Table 2500 Flanges

- SABS/SANS 1123 Table 2500/2 Slip-On Flanges

- SABS/SANS 1123 Table 2500/3 Weld Neck Flanges

- SABS/SANS 1123 Table 2500/4 Blind Flanges

- SABS/SANS 1123 Table 2500/5 Threaded Flanges

- SABS/SANS 1123 Table 2500/6 Lap Joint Flanges

- SABS/SANS 1123 Table 2500/7 Reducing Flanges

- SABS/SANS 1123 Table 2500/8 Spectacle Blind Flanges

- SABS/SANS 1123 Table 2500 Orifice Flanges with Jack Screws

- SABS/SANS 1123 Table 2500/3 Long Weld Neck Flanges

- SABS/SANS 1123 Table 2500/4 Blank-Off Flanges

Industries and Applications of SABS/SANS 1123 Table 2500 Flanges:

| Industry | Application |

|---|---|

| Oil & Gas | Pipelines, compressor stations, offshore platforms |

| Power Plants | High-pressure steam lines, condensate return systems |

| Petrochemicals | Reactors, processing vessels, chemical distribution lines |

| Water Treatment | RO systems, desalination, pressure control loops |

| Marine | Ballast lines, deck piping, seawater circulation systems |

| Mining & Minerals | Slurry pipelines, high-pressure ore processing units |

Frequently Asked Questions (FAQs) about SABS/SANS 1123 Table 2500 Series Flanges

- 1. What pressure does Table 2500 flanges support?

- Table 2500 flanges are designed to handle pressures up to 2500 kPa, suitable for heavy industrial systems.

- 2. What materials are used in SABS/SANS 1123 Table 2500 flanges?

- These flanges are available in Carbon Steel, SS 304/316, Duplex, Inconel, Monel, Copper Nickel, and Titanium.

- 3. Are custom flange sizes available?

- Yes, custom sizes and face types (RF, FF) can be manufactured on request to suit project specifications.

- 4. Do you provide MTCs and third-party inspection?

- Yes, we offer EN 10204 3.1/3.2 certificates and third-party inspections from agencies like BV, TUV, DNV, SGS, etc.

- 5. Where are these flanges typically used?

- Commonly used in oil & gas plants, refineries, chemical units, shipbuilding, and desalination plants.

- 6. What standards do SABS/SANS 1123 Table 2500 flanges comply with?

- They follow the South African Bureau of Standards (SABS) and South African National Standards (SANS) 1123, and are dimensionally compatible with BS and ASTM standards in many cases.

- 7. What face types are available for these flanges?

- SABS/SANS 1123 Table 2500 flanges are available in Raised Face (RF) and Flat Face (FF) configurations, depending on the application and pressure class.

- 8. Can Table 2500 flanges be used in offshore environments?

- Yes, when manufactured from corrosion-resistant materials like Super Duplex, Inconel, or Monel, these flanges are ideal for offshore and marine applications.

- 9. What gasket types are compatible with these flanges?

- They are compatible with spiral wound gaskets, ring gaskets, and full-face gaskets, depending on the face finish and pressure requirements.

- 10. Are these flanges suitable for cyclic temperature and pressure conditions?

- Yes, especially when made from high-performance alloys, Table 2500 flanges perform well under cyclic conditions common in power generation and refinery processes.

- 11. Do you offer coating or anti-corrosion finishes?

- Yes, we offer hot-dip galvanizing, PTFE coating, blackodising, and other protective coatings upon request.

- 12. What is the lead time for bulk orders?

- Typical lead time ranges from 1–3 weeks depending on quantity, material, and customization. Ready stock is also available for immediate dispatch.