SABS/SANS 1123 Table 1600/2 to 1600/8 Flanges

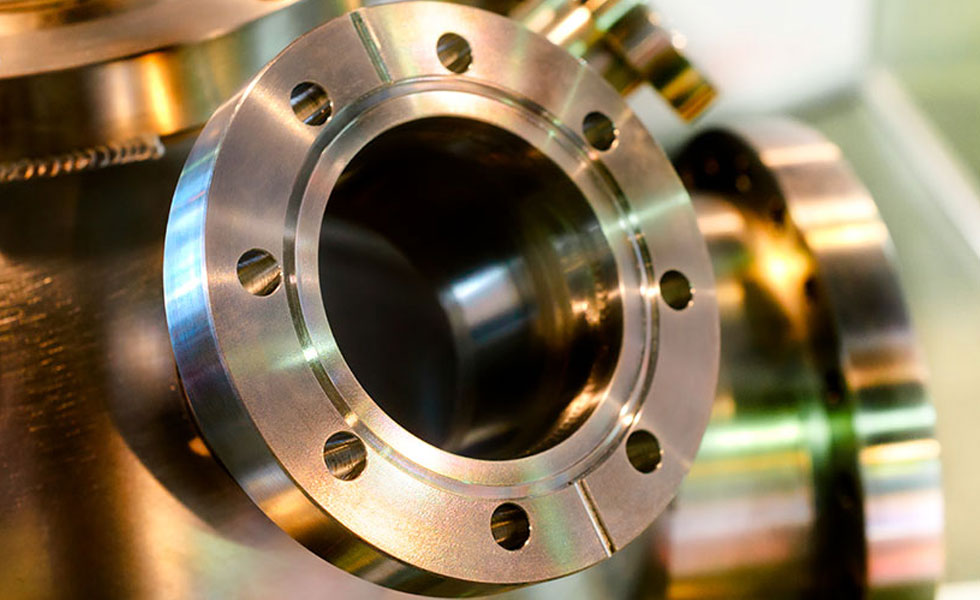

Manufacturer and Supplier of SABS/SANS 1123 Table 1600/2 to 1600/8 Flanges in Various Material Grades and Types. SABS/SANS 1123 Table 1600/2 to 1600/8 Flanges Manufacturer in Mumbai, India. We supply a complete range of SABS/SANS 1123 Table 1600/2 to Table 1600/8 Slip-On Flanges, Weld Neck Flanges, Blind Flanges, Threaded Flanges, and Lap Joint Flanges as per the South African Standard SANS 1123 specifications.

Carbon Steel SABS/SANS 1123 Table 1600/2 Slip-On Flanges Supplier, Stainless Steel Table 1600/3 Weld Neck Flanges Exporter, Alloy Steel Table 1600/4 Blind Flanges Stockist, Copper Nickel Table 1600/5 Threaded Flanges Distributor, Inconel Table 1600/6 Lap Joint Flanges Manufacturer, Monel SANS 1123 Table 1600 Flanges, Hastelloy Table 1600/7 Flanges, Titanium Table 1600/8 Flanges, and Duplex Steel SABS/SANS 1123 Table 1600/2 to 1600/8 Flanges Manufacturer & Exporter in Mumbai, India.

SABS/SANS 1123 Table 1600/2 to 1600/8 flanges are engineered to meet the high-pressure requirements of South African piping systems and are widely used across critical industries. These flanges are manufactured in compliance with the SANS 1123 standard and are offered in various configurations including Slip-On, Weld Neck, Blind, Threaded, and Lap Joint. With pressure ratings suitable for demanding environments and material options such as Carbon Steel, Stainless Steel, Duplex Steel, Copper Nickel, and high-performance alloys like Inconel and Hastelloy, these flanges ensure long-lasting, leak-proof performance under high-stress conditions.

As a leading manufacturer and exporter based in Mumbai, India, we supply SABS/SANS 1123 Table 1600/2 to 1600/8 flanges in a comprehensive size range, with customizable face finishes (RF/FF), special coatings, and tailored drilling options. All flanges undergo stringent quality checks and are supplied with EN 10204 3.1/3.2 certification, as well as third-party inspections from TUV, Lloyds, BV, and DNV upon request. These flanges are extensively used in oil & gas refineries, chemical plants, power generation facilities, desalination units, and marine infrastructure. For inquiries or a quick quote, contact us at sales@wernerflanges.com.

Stainless Steel 316 SABS/SANS 1123 Table 1600/2 Flanges, Carbon Steel SABS 1123 Table 1600/3 Slip-On Flanges, Duplex Steel S31803 SANS 1123 Table 1600/4 Weld Neck Flanges, Super Duplex S32750 SABS 1123 Table 1600/5 Blind Flanges, Titanium SABS/SANS 1123 Table 1600/6 Flanges, Copper Nickel SABS 1123 Table 1600/7 Threaded Flanges, CuNi SANS 1123 Table 1600/8 Lap Joint Flanges, Inconel SABS/SANS 1123 Table 1600/4 Weld Neck Flanges, Monel SABS 1123 Table 1600/2 Slip-On Flanges, SABS/SANS 1123 Table 1600 Flanges for High-Pressure Steam, Oil & Gas Pipeline Installations, Nickel Alloy SABS/SANS 1123 Table 1600 Flanges for Chemical, Refining & Energy Sectors, Carbon Steel SABS/SANS 1123 Table 1600/3 Flanges for Industrial Water Transport Systems, SABS 1123 Table 1600 Flanges at Competitive Prices in India, SANS 1123 Table 1600 Flanges Ready Stock in Mumbai, India, SABS/SANS 1123 Table 1600 Flanges for Marine, Offshore, HVAC & Process Plant Applications, SABS 1123 Table 1600/6 Flanges for High-Temperature and Aggressive Fluid Environments.

SABS/SANS 1123 Table 1600 Series Flanges Technical Specifications

| Specification | Details |

|---|---|

| Standard | SABS/SANS 1123 – South African Standard |

| Table Designation | Table 1600/2 to Table 1600/8 |

| Pressure Rating | Up to 2500 kPa (varies by table number) |

| Types | Slip-On, Weld Neck, Blind, Threaded, Lap Joint |

| Size Range | 15 NB to 1200 NB |

| Facing | Raised Face (RF), Flat Face (FF) |

| Testing & Certification | EN 10204 3.1 / 3.2, Hydrostatic Test, NDT, TPI on request |

Material Specifications for SABS/SANS 1123 Table 1600 Series Flanges

| Type of Materials | Common Specifications / Customization Available on Request * Materials conform to ASTM/ASME standards and are compatible with SABS/SANS 1123 Table 1600 Series Flanges |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347 |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Types of SABS/SANS 1123 Table 1600 Flanges

- SABS/SANS 1123 Table 1600/2 Slip-On Flanges

- SABS/SANS 1123 Table 1600/3 Weld Neck Flanges

- SABS/SANS 1123 Table 1600/4 Blind Flanges

- SABS/SANS 1123 Table 1600/5 Threaded Flanges

- SABS/SANS 1123 Table 1600/6 Lap Joint Flanges

- SABS/SANS 1123 Table 1600/7 Reducing Flanges

- SABS/SANS 1123 Table 1600/8 Spectacle Blind Flanges

- SABS/SANS 1123 Table 1600/2 Forged Slip-On Flanges

- SABS/SANS 1123 Table 1600/3 Raised Face Weld Neck Flanges

- SABS/SANS 1123 Table 1600/4 Flat Face Blind Flanges

- SABS/SANS 1123 Table 1600/5 Male-Female Threaded Flanges

- SABS/SANS 1123 Table 1600/6 Loose Backing Flanges

- SABS/SANS 1123 Table 1600/7 Compact Reducing Flanges

- SABS/SANS 1123 Table 1600/8 Figure-8 Blind & Spacer Sets

- SABS/SANS 1123 Table 1600 Orifice Flanges with Jack Screws

- SABS/SANS 1123 Table 1600/2 High Hub Slip-On Flanges

- SABS/SANS 1123 Table 1600/3 Long Weld Neck Flanges

- SABS/SANS 1123 Table 1600/4 Blank-Off Flanges

Industries and Applications of SABS/SANS 1123 Table 1600 Flanges:

| Industry | Application |

|---|---|

| Oil & Gas | Offshore platforms, pipeline flanged joints, refinery systems |

| Petrochemical | Process flow lines, reactors, heat exchanger flanges |

| Power Generation | Steam and feedwater piping, turbines, condensers |

| Water Treatment | High-pressure desalination units, effluent pipelines |

| Marine & Shipbuilding | Ballast systems, fire protection, hull piping |

| Mining & Mineral Processing | Pulp transport systems, pressure slurry pipelines |

Frequently Asked Questions (FAQs) about SABS/SANS 1123 Table 1600 Series Flanges

- 1. What is SABS/SANS 1123 Table 1600?

- Table 1600 under the SABS/SANS 1123 standard refers to high-pressure flange classes used predominantly in South African industrial applications. These are suitable for demanding service conditions involving steam, oil, gas, and chemicals.

- 2. What pressure rating do Table 1600 flanges support?

- These flanges are generally designed for working pressures up to 2500 kPa (25 bar) depending on flange size, material, and temperature rating.

- 3. What materials are available for Table 1600/2 to 1600/8 flanges?

- Available materials include Carbon Steel, Stainless Steel (304/316), Duplex, Super Duplex, Inconel, Monel, Copper Nickel, Titanium, and other high-performance alloys.

- 4. What are the dimensional ranges?

- These flanges are available from sizes 15 NB to 1200 NB. Custom sizes can be manufactured on request to suit special design needs.

- 5. What are common types of Table 1600 flanges?

- Common types include Slip-On, Weld Neck, Blind, Threaded, Lap Joint, Spectacle Blind, Orifice, and Reducing Flanges.

- 6. Can these flanges be used with ANSI/ASME or EN piping systems?

- Yes, if the dimensions and pressure ratings are matched correctly, SANS 1123 Table 1600 flanges can be adapted to international piping systems.

- 7. Do you offer third-party inspection and certification?

- Yes, we provide EN 10204 3.1 and 3.2 certifications along with TPI services from agencies like BV, TUV, DNV, SGS, and Lloyd’s Register.

- 8. What surface finishes are available?

- Standard finishes include Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ). Machined surfaces are typically finished to ANSI B16.5 requirements.

- 9. Are these flanges suitable for high-temperature applications?

- Yes, depending on the material grade, Table 1600 flanges can withstand high-temperature operations, especially in power plants and refineries.

- 10. How can I request a quote or technical datasheet?

- You can email your requirements to sales@wernerflanges.com to receive detailed specifications, pricing, and delivery timelines.