SABS/SANS 1123 Backing Ring Flanges

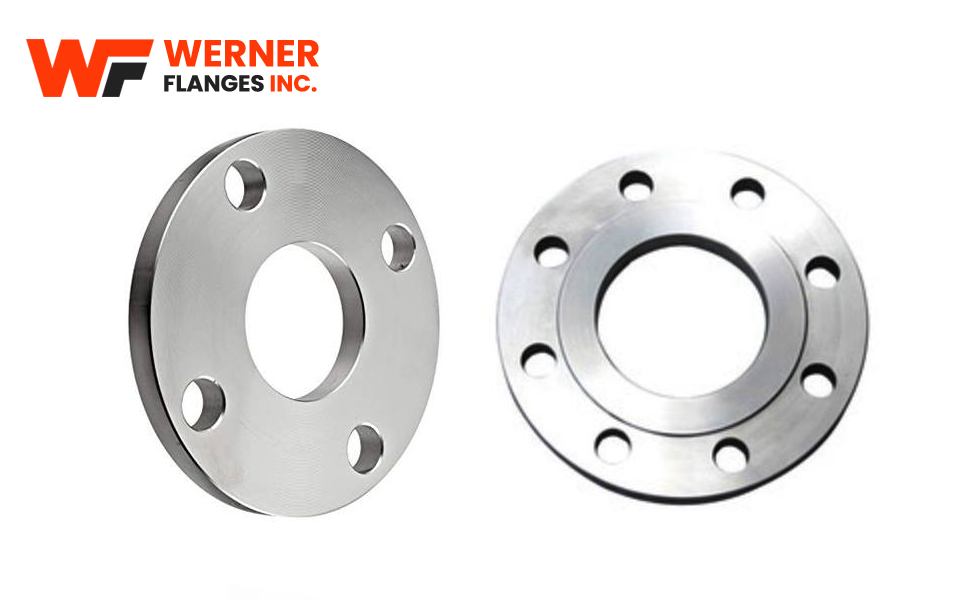

Manufacturer and Supplier of SABS/SANS 1123 Backing Ring Flanges in Various Material Grades and Sizes. SABS/SANS 1123 Backing Ring Flanges Manufacturer in Mumbai, India. We offer a complete range of SABS/SANS 1123 Backing Ring Flanges designed to meet the dimensional and pressure specifications of the South African SANS 1123 standard. Our inventory includes Slip-On type Backing Rings, suitable for use with stub ends and plastic pipe systems in low to moderate pressure pipelines.

Carbon Steel SABS/SANS 1123 Backing Ring Flanges Supplier, Stainless Steel Backing Ring Flanges Exporter, Alloy Steel Backing Rings Stockist, Copper Nickel SABS/SANS 1123 Backing Ring Flanges Distributor, Inconel & Monel Backing Ring Flanges Manufacturer, Hastelloy and Titanium SABS 1123 Backing Rings, and Duplex & Super Duplex Steel Backing Ring Flanges Manufacturer & Exporter in Mumbai, India.

As a leading manufacturer and exporter of SABS/SANS 1123 Backing Ring Flanges, we provide a comprehensive range of flanges engineered to meet the demanding requirements of HDPE piping systems and stub end connections. Our backing ring flanges are available from Table 1000/2 to 4000/8 and fabricated in a variety of material grades including Stainless Steel 304/316, Carbon Steel, Duplex Steel, Copper Nickel, Monel, Inconel, and Titanium. Designed to the specifications of South African Standard SANS 1123, these flanges are widely used in mining, chemical, water, and industrial pipelines.

SABS/SANS 1123 Backing Ring Flanges are typically used in conjunction with stub ends or plastic piping systems where corrosion resistance and easy alignment are critical. We offer forged and machined types with precise dimensions, surface finishes, and third-party inspection certifications. Our flanges are suitable for both low-pressure and high-pressure systems and are available in various face types such as raised face, flat face, and RTJ. We maintain a ready stock in Mumbai and export globally. For inquiries, contact us at sales@wernerflanges.com.

Stainless Steel 316 SABS/SANS 1123 Backing Ring Flanges, Carbon Steel SABS 1123 Backing Ring Flanges for Stub Ends, Duplex Steel S31803 SANS 1123 Backing Ring Flanges for HDPE Pipes, Super Duplex S32750 SABS 1123 Backing Rings for aggressive fluid systems, Titanium SABS/SANS 1123 Backing Rings for corrosion-sensitive environments, Copper Nickel SABS 1123 Backing Ring Flanges for marine pipelines, CuNi SANS 1123 Backing Rings for offshore and shipbuilding use, Inconel SABS/SANS 1123 Backing Rings for high-temperature plastic piping systems, and Monel SABS 1123 Backing Rings for chemical and fertilizer plants.

SABS/SANS 1123 Backing Ring Flanges are widely used with stub ends in HDPE, PVC, and thermoplastic pipelines for water treatment, irrigation, and infrastructure installations. These flanges provide reliable sealing, alignment support, and bolting integrity for non-metallic piping systems. Nickel Alloy SABS/SANS 1123 Backing Rings are ideal for desalination plants, chemical handling units, and power transmission facilities. Carbon Steel SABS/SANS 1123 Backing Rings are commonly used in mining, pulp & paper, municipal waterworks, and industrial plant layouts.

SABS/SANS 1123 Backing Ring Flanges Technical Specifications

| Standard | Specification |

|---|---|

| SABS/SANS 1123 | South African Flange Standard |

| Pressure Tables | Table 1000/2 to Table 4000/8 |

| Types | Slip-On for Stub Ends, Backing Rings |

| Sizes | 15 NB to 1200 NB |

| Face Types | Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Material Specifications for SABS/SANS 1123 Backing Ring Flanges

| Type of Materials | Common Specifications / Customization Available on Request * Materials conform to ASTM/ASME standards and are compatible with SABS/SANS 1123 Backing Ring Flanges |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347 |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Types of SABS/SANS 1123 Backing Ring Flanges

- SABS/SANS 1123 Table 1000/2 Backing Ring Flanges

- SABS/SANS 1123 Table 1600/3 Backing Ring Flanges

- SABS/SANS 1123 Table 2500/4 Backing Ring Flanges

- SABS/SANS 1123 Table 4000/5 Backing Ring Flanges

- Forged Backing Ring Flanges

- Flat Face Backing Ring Flanges

- Raised Face Backing Ring Flanges

- RTJ Type Backing Ring Flanges

- Stainless Steel 316 Backing Ring Flanges

- Carbon Steel Backing Ring Flanges for Stub Ends

Industries and Applications of SABS/SANS 1123 Backing Ring Flanges:

| Industry | Application |

|---|---|

| Water & Wastewater | HDPE pipelines, desalination plants, clean water supply |

| Mining | Slurry lines, process piping for mineral transport |

| Chemical | Corrosive fluid pipelines, chemical distribution systems |

| Power & Energy | Cooling water lines, auxiliary system pipelines |

| Marine | Saltwater intake and discharge pipelines |

| Construction | Municipal and infrastructure piping |

Frequently Asked Questions (FAQs) about SABS/SANS 1123 Backing Ring Flanges

- 1. What is a Backing Ring Flange?

- A backing ring flange is a loose-type flange used with stub ends in non-metallic piping systems such as HDPE or PVC. It provides support and clamping force for joint integrity.

- 2. What standards do these flanges follow?

- They are manufactured as per the South African SABS/SANS 1123 standard, commonly used across Africa and compatible with various international systems.

- 3. What are the common materials for SABS/SANS 1123 backing rings?

- Common materials include Carbon Steel, Stainless Steel 304/316, Duplex Steel, Copper Nickel (CuNi), Inconel, Monel, Titanium, and Nickel Alloys.

- 4. Where are backing ring flanges typically used?

- They are used in water treatment plants, irrigation systems, mining pipelines, HDPE gas lines, chemical transport systems, and industrial wastewater applications.

- 5. Are SANS 1123 backing rings compatible with stub ends?

- Yes, they are designed specifically to work with stub ends or HDPE fittings to create leak-proof, easy-to-align flange connections.

- 6. What pressure ratings are available for backing ring flanges?

- SABS/SANS 1123 backing ring flanges come in multiple pressure tables such as Table 1000, 1600, 2500, and 4000, from 1000/2 to 4000/8.

- 7. Do you provide corrosion-resistant coatings?

- Yes, we offer hot-dip galvanizing, epoxy coating, and zinc plating options based on customer requirements for harsh or corrosive environments.

- 8. Can you provide third-party inspection certificates?

- Yes, we provide inspection and testing certifications like EN 10204 3.1/3.2 and TPI from agencies such as TUV, BV, SGS, and Lloyd’s Register.

- 9. What sizes are available for SANS 1123 backing rings?

- We manufacture these flanges from 15 NB (1/2″) up to 1200 NB (48″), with custom dimensions available on request.

- 10. Do you offer fast delivery for project requirements?

- Yes, we maintain ready stock in Mumbai and offer express delivery for urgent project needs across India and international destinations.