ISO 9624 Flanges – Precision Engineered by Werner Flanges Inc.

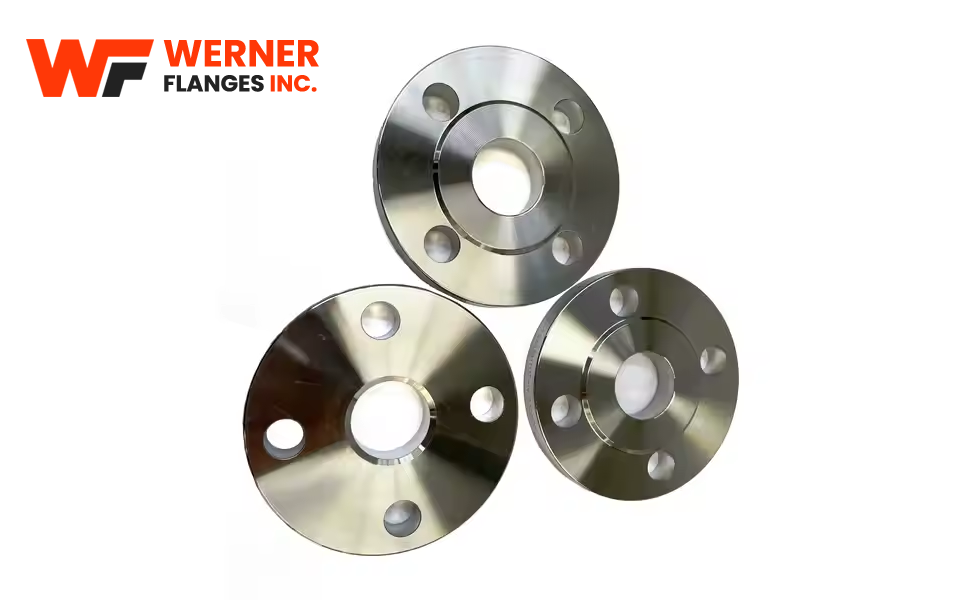

ISO 9624 Flanges are precision mechanical components primarily used in medical and laboratory equipment to connect tubular parts. Developed in compliance with ISO 9624 standards, these flanges are manufactured with tight tolerances, ensuring reliable and leak-proof connections. Werner Flanges Inc. produces ISO 9624 flanges with a strong emphasis on dimensional accuracy, corrosion resistance, and mechanical strength—ideal for sterile and high-precision applications.

ISO 9624 Flanges are widely used in medical devices, analytical instrumentation, and pharmaceutical processing systems. Their compatibility with sterilization procedures and their hygienic design make them indispensable in cleanroom environments. These flanges are particularly suited for applications requiring precision assembly and disassembly, including fluid transport systems in biopharma and diagnostic labs.

Werner Flanges Inc. offers ISO 9624 flanges in a wide range of sizes and materials, including stainless steel and high-performance alloys. Whether you require small-batch deliveries or large project quantities, we maintain ready-to-ship inventory to meet your operational deadlines. Custom sizes and finishes can also be supplied upon request, with full traceability and quality documentation.

With decades of experience in precision flange manufacturing, Werner Flanges Inc. is a trusted global supplier to medical OEMs, EPC contractors, and system integrators. Our ISO-certified production facilities ensure every ISO 9624 flange meets international standards. We combine advanced machining, rigorous inspection, and responsive customer service to deliver unmatched quality and reliability.

ISO 9624 Flanges – Precision Engineered by Werner Flanges Inc. Technical Specifications

| Specification | Details |

|---|---|

| Standard | ISO 9624 |

| Flange Types | Weld Neck Flange, Socket Weld Flange, Slip-On Flange |

| Pressure Ratings | Up to 10 bar (varies by application) |

| Size Range | 6 mm to 50 mm OD |

| Facing Types | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Manufacturing Process | Forged / Machined |

| Testing & Certification | PMI Testing, Hydrostatic Test, Dimensional Inspection, ISO 13485 Compliance (on request), RoHS & REACH Compliance |

Material Specifications for ISO 9624 Flanges – Precision Engineered by Werner Flanges Inc.

| Type of Materials | Common Specifications / Customization Available on Request |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347 |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Types of ISO 9624 Flanges – Precision Engineered by Werner Flanges Inc.

- ISO 9624 Precision Flange

- EN 9624 Flange

- Stainless Steel Medical Flange

- ISO 9624 Instrument Flange

- ISO 9624 Weld Flange

- ISO 9624 Tube Connector

- ISO 9624 Flange for Medical Devices

Industries and Applications of ISO 9624 Flanges – Precision Engineered by Werner Flanges Inc.

| Industry | Application |

|---|---|

| Oil & Gas Industry | Used extensively in upstream, midstream, and downstream operations for high-pressure piping and processing systems requiring robust sealing solutions. |

| Petrochemical & Chemical Processing | Ideal for handling corrosive chemicals and high-temperature pipelines in refining and chemical manufacturing processes. |

| Power Generation | Installed in thermal, nuclear, and hydroelectric power plants for critical pressure applications and steam systems. |

| Water Treatment & Desalination | Used in high-pressure water distribution, desalination, and wastewater treatment pipelines ensuring durability and leak resistance. |

| Marine & Offshore Industry | Suitable for seawater piping systems, ballast systems, and pressure vessels in marine engineering and offshore platforms. |

| Pharmaceutical Industry | Ensures sanitary, high-pressure fluid handling in sterile environments and cleanroom process systems. |

| Food & Beverage Industry | Used in hygienic and high-pressure processing lines where corrosion resistance and strength are critical. |

| Mining & Mineral Processing | Supports slurry transport systems and ore processing pipelines in mining operations. |

Frequently Asked Questions (FAQs) about ISO 9624 Flanges – Precision Engineered by Werner Flanges Inc.

Q1: What is an ISO 9624 flange used for?

A: ISO 9624 flanges are primarily used to connect metal tubes in medical and analytical equipment where high precision and hygiene are required.

Q2: Are ISO 9624 flanges compatible with standard piping systems?

A: No, these flanges are specifically designed for precision tubing systems and are not compatible with conventional industrial piping.

Q3: What materials are typically used for ISO 9624 flanges?

A: Common materials include SS 316L, SS 304L, Duplex 2205, and Titanium Grade 2 due to their corrosion resistance and biocompatibility.

Q4: Do you provide material test certificates for ISO 9624 flanges?

A: Yes, Werner Flanges Inc. supplies ISO 9624 flanges with EN 10204 3.1 or 3.2 certification upon request.

Q5: Can ISO 9624 flanges be customized for non-standard tube sizes?

A: Absolutely. We can manufacture custom dimensions with tight tolerances for specialized applications.

Q6: What surface finishes are available?

A: Common finishes include bright annealed and electropolished, ensuring hygienic and corrosion-resistant surfaces.

Q7: What is the lead time for bulk orders?

A: Lead time depends on quantity and material, but standard sizes are usually available for immediate dispatch.