GOST 33259 PN 1.0 MPa WNRF Flanges

Manufacturer and Supplier of GOST 33259 PN 1.0 MPa Weld Neck Raised Face (WNRF) Flanges in various material grades. GOST 33259 WNRF Flanges Manufacturer in Mumbai, India. Carbon Steel GOST 33259 PN 1.0 MPa Weld Neck Raised Face Flanges, Stainless Steel GOST 33259 PN 1.0 MPa WNRF Flanges, Alloy Steel GOST 33259 WNRF Flanges, ASTM A182 Stainless Steel GOST 33259 PN 1.0 MPa Weld Neck Raised Face Flanges, Alloy 20 GOST 33259 WNRF Flanges, Copper Nickel GOST 33259 WNRF Flanges, PN 1.0 MPa GOST 33259 Weld Neck Raised Face Flanges Exporter in Mumbai, India.

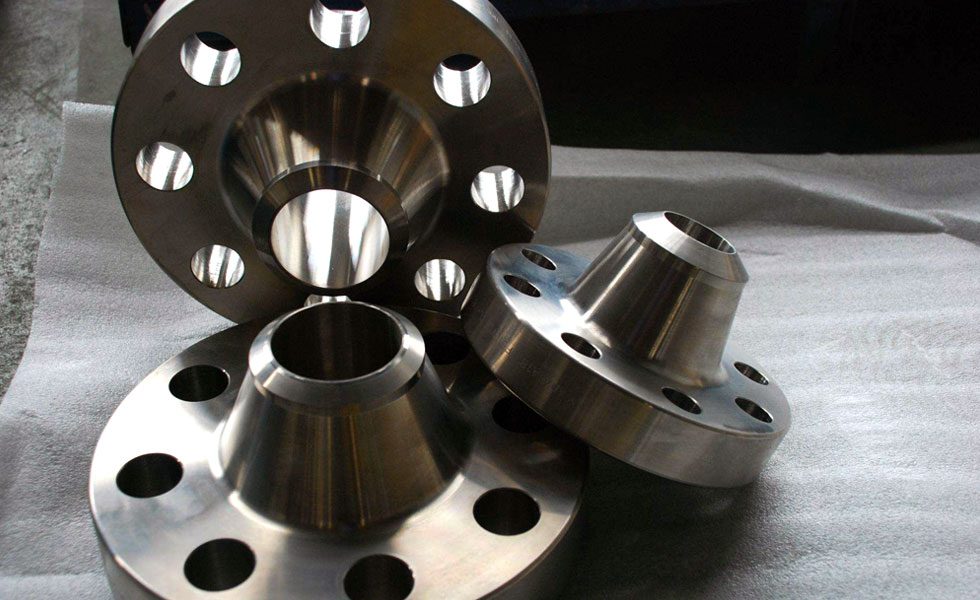

Werner Flanges Inc. is a reputable producer and supplier of high-quality GOST 33259 PN 1.0 MPa Weld Neck Raised Face (WNRF) Flanges that exceed strict industrial specifications. These flanges are designed to be durable and reliable in pressure pipe systems running at 1.0 MPa, making them excellent for industries such as oil and gas, chemical processing, and water treatment. Our GOST 33259 WNRF flanges are precision-machined from high-quality materials such as carbon steel, stainless steel, high nickel alloys, alloy steel and more ensuring leak-proof couplings and good corrosion and wear resistance. Whether you want conventional sizes or unique specifications, Werner Flanges Inc. provides consistent quality that is suited to your project needs.

Werner Flanges Inc. prioritizes customer satisfaction. We offer experienced advice to assist you choose the best flange type and material grade for optimal performance and safety in your system. Our devoted crew is prepared to assist your purchases with timely delivery and cheap price. To inquire or place an order for GOST 33259 PN 1.0 MPa Weld Neck Raised Face Flanges, please contact us at sales@wernerflanges.com immediately and enjoy the dependable service of industry-leading flange solutions.

Werner Flanges Inc. is one of the leading manufacturers and suppliers of Duplex Steel GOST 33259 PN 1.0 MPa Weld Neck Raised Face (WNRF) Flanges, Industrial GOST 33259 PN 1.0 MPa WNRF Flanges, High Pressure GOST 33259 WNRF Flanges, Inconel 601 GOST 33259 PN 1.0 MPa WNRF Flanges, Hastelloy C276 GOST 33259 PN 1.0 MPa WNRF Flanges, Monel K500 GOST 33259 PN 1.0 MPa WNRF Flanges, Carbon Steel GOST 33259 PN 1.0 MPa WNRF Flanges, Stainless Steel 316 GOST 33259 WNRF Flanges, Titanium GOST 33259 PN 1.0 MPa WNRF Flanges, and more.

GOST 33259 PN 1.0 MPa WNRF Flanges Technical Specifications

| Specification | Details |

|---|---|

| Standard | GOST 33259-2015 |

| Pressure Rating | PN 1.0 MPa (Approx. 145 PSI) |

| Flange Type | Weld Neck Raised Face (WNRF) Flange |

| Facing Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Size Range | DN 10 to DN 2000 (Custom sizes available) |

| Temperature Range | -20°C to +250°C (Depends on material) |

| Applications | Oil & Gas, Petrochemical, Power Plants, Water Treatment, Marine & Industrial Sectors |

| Manufacturing Process | Forged / Machined |

| Certification | EN 10204 3.1 / 3.2, IBR, NACE MR0175 (if applicable) |

Material Specifications for GOST 33259 PN 1.0 MPa WNRF Flanges

| Type of Materials | Common Specifications / Customization Available on Request * Materials conform to ASTM/ASME standards and are compatible with GOST 33259 PN 1.0 MPa WNRF Flanges |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347 |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Types of GOST 33259 PN 1.0 MPa WNRF Flanges

| Type | Description |

|---|---|

| Blind WNRF Flanges (Type 05) | Used to seal the ends of pipelines, valves, and pressure vessel openings, preventing flow. |

| Slip-On WNRF Flanges (Type 01) | Designed to slip over the pipe, suitable for low-pressure applications with easy installation. |

| Weld Neck WNRF Flanges (Type 11) | Provides strong welded connections ideal for high-stress environments, ensuring durability and leak resistance. |

| Threaded WNRF Flanges (Type 13) | Can be screwed onto pipes without welding, typically used in small diameter and low-pressure piping systems. |

| Lap Joint WNRF Flanges (Type 12) | Used with stub ends for piping systems that require frequent dismantling and maintenance. |

| Socket Weld WNRF Flanges (Type 14) | Ideal for small bore pipes, providing strong socket weld connections with leak-proof joints. |

| Loose WNRF Flanges | Commonly paired with lap joint stub ends for quick and easy assembly or disassembly of piping systems. |

Industries and Applications of GOST 33259 PN 1.0 MPa WNRF Flanges:

| Industries | Applications |

|---|---|

| Oil & Gas Industry | Used extensively in pipelines, refineries, and offshore platforms for safe and reliable connections under moderate pressure conditions. |

| Petrochemical Plants | Applied in chemical processing systems to handle various fluids and gases with leak-proof flange joints. |

| Power Generation | Installed in cooling water systems, steam lines, and auxiliary piping in thermal and nuclear power plants. |

| Water Treatment Facilities | Used to connect pipes in filtration, purification, and distribution systems ensuring corrosion resistance and reliability. |

| Marine and Shipbuilding | Utilized in marine piping systems requiring high durability against saltwater corrosion and ease of maintenance. |

| Industrial Manufacturing | Applied across general industrial applications for fluid transfer systems, compressed air lines, and hydraulic systems. |

| Food & Beverage Industry | Used in hygienic piping systems where corrosion resistance and cleanability are crucial. |

Frequently Asked Questions (FAQs) about GOST 33259 PN 1.0 MPa WNRF Flanges

- 1. What is the pressure rating of GOST 33259 PN 1.0 MPa WNRF Flanges?

- These flanges have a pressure rating of 1.0 MPa (approximately 145 PSI), suitable for moderate pressure applications in various industries.

- 2. What materials are used for GOST 33259 PN 1.0 MPa WNRF Flanges?

- They are manufactured from materials like carbon steel, stainless steel, alloy steel, and sometimes specialty alloys to meet diverse application requirements.

- 3. What types of GOST 33259 PN 1.0 MPa WNRF Flanges are available?

- Common types include Weld Neck, Slip-On, Blind, Threaded, Lap Joint, Socket Weld, and Loose Flanges.

- 4. Where are these flanges typically used?

- They are used in oil & gas pipelines, petrochemical plants, power generation, water treatment, marine applications, and industrial manufacturing.

- 5. How do GOST 33259 PN 1.0 MPa WNRF Flanges ensure leak-proof connections?

- The raised face design improves sealing surface contact with gaskets, ensuring reliable and leak-proof joints under pressure.

- 6. Can these flanges be customized?

- Yes, they can be customized in terms of size, material, pressure rating, and flange type to suit specific project needs.

- 7. What standards do these flanges comply with?

- They comply with GOST 33259-2015 and other applicable certifications like EN 10204, IBR, and NACE MR0175 if required.

- 8. How can I select the right flange type for my application?

- Selection depends on factors like pressure requirements, ease of installation, maintenance needs, and system design. Consulting with experts ensures the best choice.