What is a Lap Joint Flange?

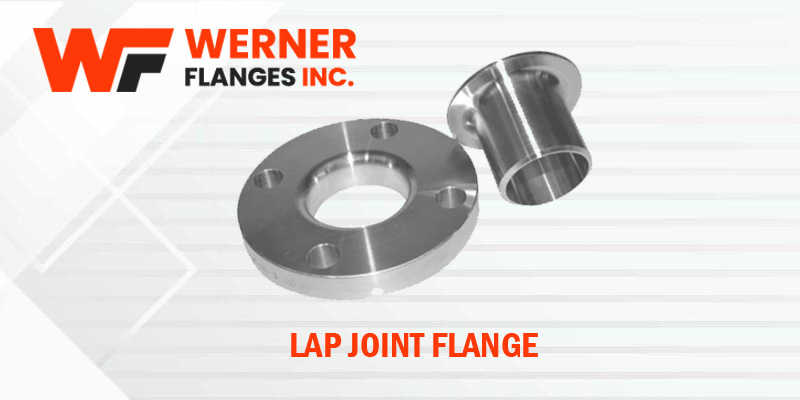

A Lap Joint Flange is a type of flange that is used in conjunction with a stub end. Unlike other flanges that are directly welded to the pipe, the Lap Joint Flange is designed to rotate around the stub end, allowing for easier alignment of bolt holes during assembly. This design is particularly beneficial in systems that require frequent disassembly for inspection, cleaning, or maintenance.Key Components of a Lap Joint Flange

- Flange: The Lap Joint Flange itself is a flat, circular disc with bolt holes around the perimeter. It has a slightly raised face that matches the stub end.

- Stub End: The stub end is a short piece of pipe with one end flared outwards to form a lap joint. The other end is welded to the pipe. The stub end is the component that actually connects to the piping system, while the Lap Joint Flange provides the necessary support and sealing.

- Gasket: A gasket is placed between the Lap Joint Flange and the stub end to ensure a tight seal, preventing leaks in the system.

Design and Specifications

Material Selection

Lap Joint Flanges are manufactured from a variety of materials, including:- Carbon Steel: Commonly used in general-purpose applications due to its strength and affordability.

- Stainless Steel: Preferred for corrosive environments, such as chemical processing and food industries.

- Alloy Steel: Used in high-temperature and high-pressure applications, such as power plants and oil refineries.

- Nickel Alloys: Suitable for extreme conditions, including high temperatures and corrosive environments.

Dimensions and Standards

Lap Joint Flanges are manufactured in accordance with various international standards, including:- ASME B16.5: Covers pipe flanges and flanged fittings for sizes NPS ½” to NPS 24”.

- ASME B16.47: Covers large-diameter steel flanges for sizes NPS 26” to NPS 60”.

- EN 1092-1: European standard for flanges and their joints.

Pressure Ratings

Lap Joint Flanges are available in different pressure ratings, which indicate the maximum pressure they can withstand. Common pressure ratings include:- 150#: Suitable for low-pressure applications.

- 300#: Used in medium-pressure systems.

- 600#: Designed for high-pressure applications.

- 900#, 1500#, and 2500#: Used in extremely high-pressure systems.