DIN PN6 - PN40 Threaded Flanges

DIN PN6 Threaded Flanges Manufacturer, DIN PN10 Threaded Flanges Stockist, DIN PN16 Threaded Flanges Supplier, DIN PN25 Threaded Flanges Exporter, DIN PN40 Threaded Flanges, DIN Threaded Flanges Supplier in India, Custom DIN Threaded Flanges in Exotic Alloys, Marine-Grade DIN Copper Nickel Threaded Flanges, Stainless Steel DIN Threaded Flanges, Titanium DIN PN25 Threaded Flanges Manufacturer, Duplex Steel DIN PN10 Threaded Flanges Exporter, DIN PN16 Threaded Flanges in Stainless Steel, Hastelloy DIN Threaded Flanges Supplier, Stainless Steel 304 DIN Threaded Flanges Manufacturer in India.

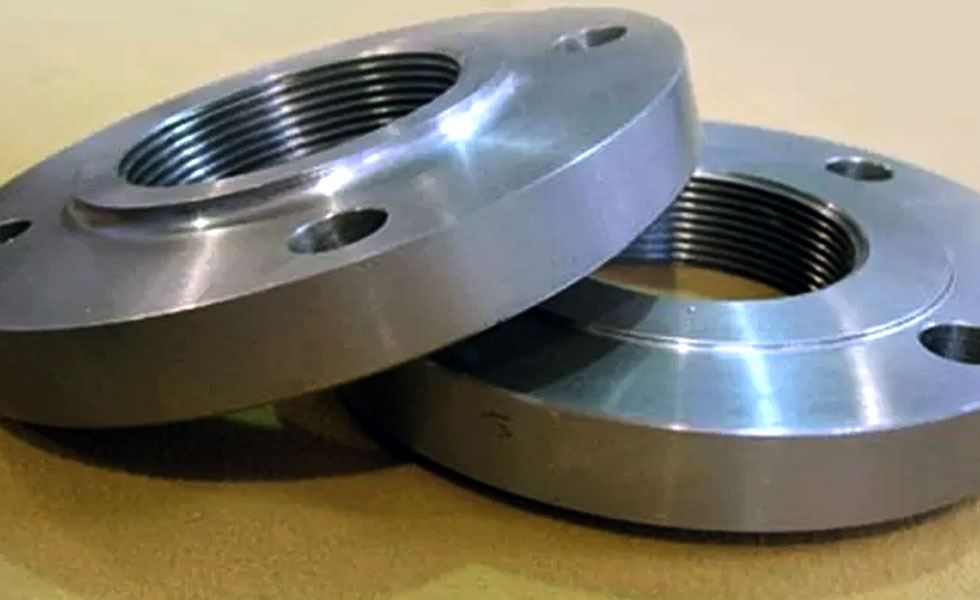

Werner Flanges Inc.’s DIN PN6 – PN40 Threaded Flanges are designed to provide trustworthy, leak-proof connections in a variety of low- to high-pressure pipe systems. These DIN-compliant flanges are suitable for situations where welding is not an option, such as in explosive zones or high-vibration conditions. The threaded design enables quick and easy installation, making them popular in sectors such as oil and gas, petrochemical, water treatment, and HVAC systems. Our threaded flanges, which have pressure ratings ranging from PN6 to PN40, provide adaptability and solid performance in a variety of operating environments.

Werner Flanges Inc. manufactures these flanges using high-quality materials such as carbon steel, stainless steel, and special alloys, ensuring outstanding corrosion resistance and endurance. To fulfill international standards and client demands, all items must go through rigorous quality inspections. Whether you want conventional sizes or customised solutions, our staff is ready to help with experienced advice and quick turnaround. For further information, specs, or to make an order, please contact us at sales@wernerflanges.com now.

SS 316 DIN PN6 Threaded Flanges, Carbon Steel DIN Threaded Flanges, Duplex Steel S31803 DIN Threaded Flanges, Super Duplex S32750 DIN Threaded Flanges, Titanium DIN Threaded Flanges, Copper Nickel DIN Threaded Flanges, CuNi DIN PN16 Threaded Flanges, Inconel DIN PN40 Threaded Flanges, Monel DIN PN6 Threaded Flanges, DIN PN40 Threaded Flanges for High Pressure Applications, Nickel Alloy DIN PN40 Threaded Flanges for Heat Exchangers, Carbon Steel DIN PN6 Threaded Flanges for Water Pipelines, DIN Threaded Flanges Price, DIN PN10 Threaded Flanges Ready Stock, DIN Threaded Flanges for Oil & Gas, DIN Threaded Flanges for Petrochemical Applications.

DIN PN6 - PN40 Threaded Flanges Technical Specifications

| Specification | Details |

|---|---|

| Standards | DIN EN 1092-1 (replaces older DIN standards like DIN 2565, DIN 2566) |

| Pressure Ratings (PN) | PN6, PN10, PN16, PN25, PN40 |

| Flange Type | Threaded Flanges (Screwed Flanges) |

| Size Range | DN 10 to DN 600 (custom sizes available on request) |

| Face Types | Raised Face (RF), Flat Face (FF) |

| Connection | Screwed/threaded connection to pipe ends; no welding required |

| Thread Type | Typically BSP or NPT threads depending on application |

| Dimensions | In accordance with DIN EN 1092-1 specifications |

| Testing | Hydrostatic pressure testing, dimensional inspection, thread verification |

| Surface Finish | Precision machined surface for proper sealing and fit |

Material Specifications for DIN PN6 - PN40 Threaded Flanges

| Type of Materials | Common Specifications / Customization Available on Request * Materials conform to ASTM/ASME standards and are compatible with DIN PN6 – PN40 Threaded Flanges |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347, F904L, etc. |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Understanding Pressure Ratings in DIN Threaded Flanges:

In DIN Threaded Flanges, pressure ratings are represented by the prefix “PN,” which stands for “Pressure Nominal.” Common PN ratings include PN6, PN10, PN16, PN25, and PN40, each reflecting the maximum pressure (in bars) that the flange can withstand at a reference temperature, which is commonly 20°C. Under typical settings, a PN16 flange can sustain 16 bars (or roughly 232 psi) of pressure. These ratings are critical in determining the best flange for safe and dependable operation in various pipe systems, particularly when dealing with changing fluid pressures and temperatures.

Understanding and selecting the appropriate PN rating is critical to preventing pipeline failures or leaks. For lower-pressure systems, such as water pipes, PN6 or PN10 flanges may be sufficient. However, in high-pressure applications such as oil and gas or steam lines, PN25 or PN40 flanges are preferred. Werner Flanges Inc. provides a large assortment of DIN PN6-PN40 Threaded Flanges that are manufactured to stringent specifications, assuring both safety and performance. Contact sales@wernerflanges.com for expert advice or to place an order.

Factors to Consider When Selecting DIN Threaded Flange Pressure Ratings:

- Operating Pressure and Temperature: Always select a flange PN rating that can handle both the system’s maximum pressure and temperature. Higher temperatures reduce the pressure tolerance of flanges.

- Type of Fluid or Gas: Corrosive or hazardous media such as acids, steam, or gases require flanges made from compatible, durable materials that can handle the pressure safely.

- Material Compatibility: Choose materials like stainless steel, carbon steel, or exotic alloys (e.g., Inconel, Monel) based on chemical compatibility and strength requirements.

- Pipe Size and Wall Thickness: Larger diameter pipes or thicker walls typically require flanges with higher pressure ratings for a secure, leak-free connection.

- Mechanical Loads: Consider external loads such as thermal expansion, vibration, and bending forces which may impact flange performance under pressure.

- Installation Environment: Harsh environmental conditions like marine atmospheres, underground pipelines, or high-humidity areas can influence material selection and required pressure ratings.

- Safety and Regulatory Compliance: Ensure flanges meet DIN EN 1092-1 standards and comply with industry-specific codes or project specifications for pressure equipment.

- Application Type: Applications such as heat exchangers, high-pressure lines, or chemical transfer require higher-rated flanges to maintain system integrity.

- Manufacturer Support: Work with reliable manufacturers like Werner Flanges Inc. for guidance, testing certifications, and pressure class recommendations tailored to your specific needs.

- Need Help? For expert support or custom DIN PN6–PN40 Threaded Flanges, email us at sales@wernerflanges.com.

Advantages of Using Properly Rated DIN Threaded Flanges:

- Enhanced Safety: Correct pressure ratings help prevent leaks, blowouts, and flange failures, ensuring the safe operation of pipelines and equipment.

- Leak-Free Connections: Properly rated flanges create tight seals, minimizing the risk of fluid or gas escape, especially in high-pressure environments.

- System Reliability: Using flanges that match system specifications ensures stable, long-term performance and reduces the chances of unplanned downtime.

- Cost Efficiency: Avoids expensive repairs, replacements, and shutdowns by preventing failures due to under-rated flange selection.

- Compliance with Industry Standards: Properly rated DIN threaded flanges meet DIN EN 1092-1 standards, ensuring regulatory and project compliance.

- Versatile Application: Rated flanges can be safely used across diverse industries such as oil & gas, water treatment, chemical processing, and HVAC systems.

- Material Optimization: Ensures the selected flange material can withstand the specific pressure and temperature conditions, maximizing performance and durability.

- Ease of Maintenance: Proper flange selection reduces the need for frequent maintenance, making system servicing more efficient and predictable.

- Operational Confidence: Engineers and operators can trust in the mechanical integrity of the system when correct pressure-rated flanges are used.

- Need Expert Guidance? Contact Werner Flanges Inc. at sales@wernerflanges.com for reliable DIN PN6–PN40 threaded flanges tailored to your pressure requirements.

Types of DIN PN6 - PN40 Threaded Flanges

| Type | Description |

|---|---|

| DIN PN6 Threaded Flanges | Best suited for low-pressure applications such as water pipelines, HVAC systems, and non-critical fluid transport where ease of installation and maintenance is essential. |

| DIN PN10 Threaded Flanges | Used in medium-duty operations like compressed air systems, fire protection lines, and low-pressure industrial processes, offering a reliable threaded connection without welding. |

| DIN PN16 Threaded Flanges | Ideal for applications in industrial water lines, moderate gas supply networks, and general chemical processing where higher pressure handling is required. |

| DIN PN25 Threaded Flanges | Engineered for high-pressure piping in steam systems, refinery processes, and mechanical plants, offering secure, leak-proof joints without welding. |

| DIN PN40 Threaded Flanges | Recommended for extremely high-pressure environments such as offshore platforms, oil & gas pipelines, and heat exchanger systems where mechanical strength and pressure integrity are critical. |

DIN PN6 - PN40 Threaded Flanges: Dimensions & Pressure Ratings

| Nominal Size (DN) | Threaded Flange OD (mm) | Bolt Circle (PCD) (mm) | Number of Bolt Holes | Bolt Hole Diameter (mm) | Flange Thickness (mm) | Thread | Pressure Rating (Bar) |

|---|---|---|---|---|---|---|---|

| DN 15 / 1/2″ | 95 (PN6) – 105 (PN10-PN40) | 65 | 4 | 14 | 14 | BSP / NPT | 6 – 40 |

| DN 20 / 3/4″ | 105 – 115 | 75 | 4 | 14 | 16 | BSP / NPT | 6 – 40 |

| DN 25 / 1″ | 115 – 130 | 85 | 4 | 14 | 16 | BSP / NPT | 6 – 40 |

| DN 32 / 1 1/4″ | 140 – 150 | 100 | 4 | 14 | 18 | BSP / NPT | 6 – 40 |

| DN 40 / 1 1/2″ | 150 – 160 | 110 | 4 | 18 | 18 | BSP / NPT | 6 – 40 |

| DN 50 / 2″ | 165 – 180 | 125 | 4 | 18 | 20 | BSP / NPT | 6 – 40 |

| DN 65 / 2 1/2″ | 190 – 215 | 145 | 4 | 18 | 22 | BSP / NPT | 6 – 40 |

| DN 80 / 3″ | 210 – 240 | 160 | 8 | 18 | 24 | BSP / NPT | 6 – 40 |

| DN 100 / 4″ | 240 – 285 | 180 | 8 | 18 | 24 | BSP / NPT | 6 – 40 |

| DN 125 / 5″ | 270 – 320 | 210 | 8 | 18 | 26 | BSP / NPT | 6 – 40 |

| DN 150 / 6″ | 300 – 350 | 240 | 8 | 22 | 28 | BSP / NPT | 6 – 40 |

| DN 200 / 8″ | 360 – 405 | 295 | 8 | 22 | 30 | BSP / NPT | 6 – 40 |

| DN 250 / 10″ | 430 – 480 | 350 | 12 | 26 | 32 | BSP / NPT | 6 – 40 |

| DN 300 / 12″ | 485 – 535 | 400 | 12 | 26 | 34 | BSP / NPT | 6 – 40 |

Industries and Applications of DIN PN6 - PN40 Blind Flanges:

- Oil & Gas Industry: Used for connecting pipelines, valves, and equipment in upstream, midstream, and downstream operations.

- Chemical Processing: Suitable for handling corrosive and hazardous fluids in chemical plants.

- Water Treatment Plants: Employed in piping systems for potable water, wastewater, and desalination plants.

- Power Generation: Utilized in cooling water systems, steam lines, and other auxiliary piping.

- Pharmaceutical Industry: For sanitary and secure piping connections.

- Food & Beverage Industry: Ensures hygienic connections in processing and packaging lines.

- HVAC Systems: Used in heating, ventilation, and air conditioning piping installations.

- Marine & Shipbuilding: Ideal for seawater piping and other marine applications.

- General Industrial Applications: Suitable for moderate pressure fluid transport, including compressed air and gases.

Frequently Asked Questions (FAQs) about DIN PN6 - PN40 Threaded Flanges

- 1. What are DIN PN6 – PN40 Threaded Flanges?

- DIN PN6 to PN40 Threaded Flanges are flanges with internal threads that allow for a screw-on connection to pipes, designed according to DIN standards with pressure ratings from 6 to 40 bar, enabling easy installation without welding.

- 2. In which industries are DIN PN6 – PN40 Threaded Flanges commonly used?

- They are widely used in oil & gas, chemical processing, water treatment, power plants, pharmaceutical, HVAC, and marine industries.

- 3. What materials are typically used to manufacture these threaded flanges?

- Common materials include carbon steel, stainless steel, alloy steel, and corrosion-resistant alloys suitable for different operating environments.

- 4. How do I choose the correct PN rating for my application?

- Select a flange with a PN rating that matches or exceeds the maximum pressure and temperature of your piping system for safety and reliability.

- 5. What are the benefits of using threaded flanges?

- Threaded flanges allow easy assembly and disassembly without welding, reduce installation time, and are ideal for low to medium pressure systems.

- 6. Can DIN PN threaded flanges be interchanged with ANSI threaded flanges?

- No, DIN and ANSI threaded flanges differ in dimensions and thread standards, making them incompatible without adapters.

- 7. Does flange thickness vary with PN rating?

- Yes, as the PN rating increases, the flange thickness generally increases to withstand higher pressure requirements.

- 8. What standards apply to DIN PN6 – PN40 Threaded Flanges?

- DIN EN 1092-1 is the primary standard specifying the dimensions and pressure ratings for these flanges.

- 9. Are custom sizes or materials available for threaded flanges?

- Yes, many manufacturers provide custom sizes, materials, and thread types to suit specific project requirements.

- 10. Where can I buy high-quality DIN PN6 – PN40 Threaded Flanges?

- Contact trusted suppliers or manufacturers such as Werner Flanges Inc. at sales@wernerflanges.com for inquiries and orders.