DIN PN6 - PN40 Plate Flanges

DIN PN6 Plate Flanges Manufacturer, DIN PN10 Plate Flanges Stockist, DIN PN16 Plate Flanges Supplier, DIN PN25 Plate Flanges Exporter, DIN PN40 Plate Flanges, DIN Plate Flanges Supplier in India, Custom DIN Plate Flanges in Exotic Alloys, Marine-Grade DIN Copper Nickel Plate Flanges, Stainless Steel DIN Plate Flanges, Titanium DIN PN25 Plate Flanges Manufacturer, Duplex Steel DIN PN10 Plate Flanges Exporter, DIN PN16 Plate Flanges in Stainless Steel, Hastelloy DIN Plate Flanges Supplier, Stainless Steel 304 DIN Plate Flanges Manufacturer in India.

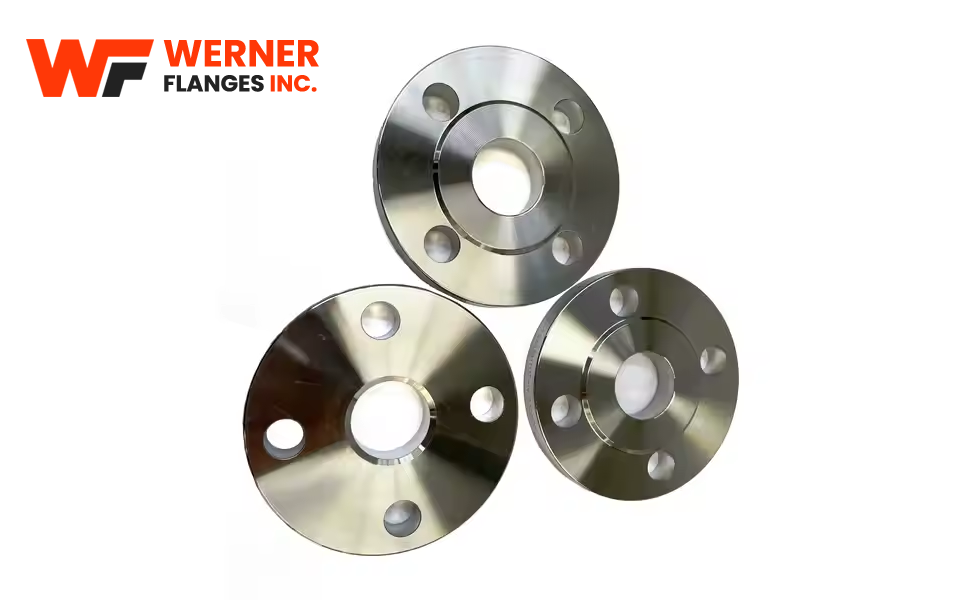

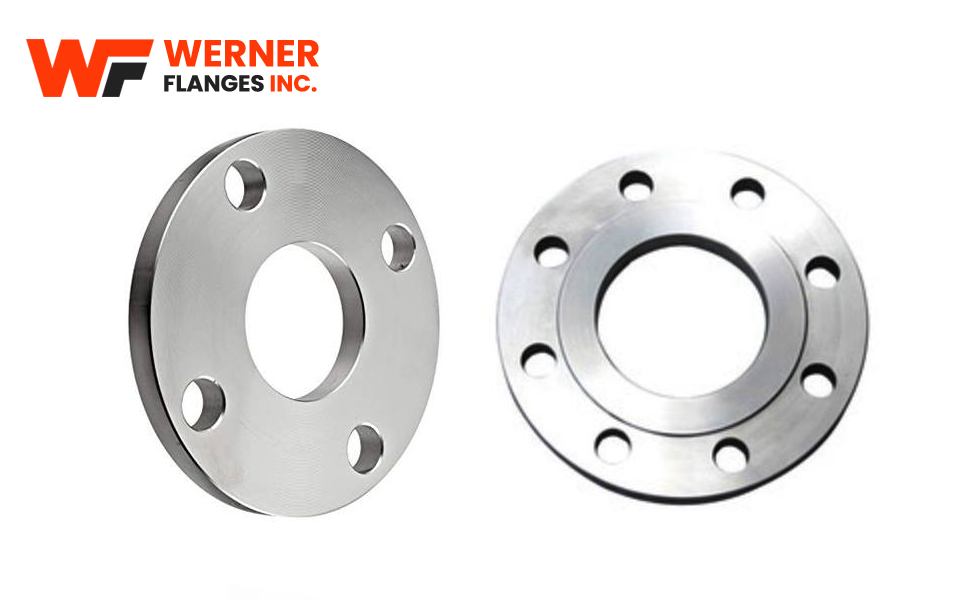

Werner Flanges Inc. is an established manufacturer and exporter of high-quality DIN PN6 to PN40 Plate Flanges designed to handle a variety of pressure requirements in industrial pipe systems. These flanges are intended to provide efficient and secure bolted connections in applications such as water treatment, oil and gas, petrochemicals, and power generation. Our Plate Flanges are manufactured to DIN standards and provide outstanding dimensional precision, corrosion resistance, and ease of installation in both low-pressure (PN6, PN10) and high-pressure (PN25, PN40) systems.

Our DIN Plate Flanges are available in a variety of materials, including stainless steel, carbon steel, duplex, and high nickel alloys, and may be used for both conventional and specialized applications. Werner Flanges Inc. provides reliable flanges for tough environments and precision-critical applications. For questions, technical help, or a price, please email sales@wernerflanges.com.

SS 316 DIN PN6 Plate Flanges, Carbon Steel DIN Plate Flanges, Duplex Steel S31803 DIN Plate Flanges, Super Duplex S32750 DIN Plate Flanges, Titanium DIN Plate Flanges, Copper Nickel DIN Plate Flanges, CuNi DIN PN16 Plate Flanges, Inconel DIN PN40 Plate Flanges, MonelDIN PN6 Plate Flanges, DIN PN40 Plate Flanges for High Pressure Applications, Nickel Alloy DIN PN40 Plate Flanges for Heat Exchangers, Carbon Steel DIN PN6 Plate Flanges for Water Pipelines, DIN Plate Flanges Price, DIN PN10 Plate Flanges Ready Stock, DIN Plate Flanges for Oil & Gas, DIN Plate Flanges for Petrochemical Applications

DIN PN6 - PN40 Plate Flanges Technical Specifications

| Specification | Details |

|---|---|

| Product Name | DIN PN6 – PN40 Plate Flanges |

| Pressure Ratings | PN6, PN10, PN16, PN25, PN40 |

| Design Standard | DIN (Deutsches Institut für Normung) |

| Flange Type | Plate Flanges |

| Sizes | DN15 to DN1200 (1/2” to 48”) or as per customer requirement |

| Facing Types | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Drilling Specifications | As per DIN standard or customized |

| Manufacturing Method | Forged / Machined |

| Testing & Certification | EN 10204 3.1/3.2, IBR, NACE MR0175 (if applicable) |

Material Specifications for DIN PN6 - PN40 Plate Flanges

| Type of Materials | Common Specifications / Customization Available on Request * Materials conform to ASTM/ASME standards and are compatible with DIN PN6 – PN40 Plate Flanges |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347, F904L, etc. |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Understanding Pressure Ratings in DIN Plate Flanges:

Pressure ratings in DIN Plate Flanges are designated by the term “PN” (Pressure Nominale), which indicates the maximum pressure the flange can withstand in bars at a reference temperature of 20°C. These ratings are essential for determining the suitability of a flange for specific applications, particularly where system pressure and temperature play a critical role. Common pressure ratings include PN6, PN10, PN16, PN25, and PN40. PN6 is typically used in low-pressure systems such as irrigation and water supply. PN10 and PN16 are suitable for medium-pressure applications in industries like HVAC, water distribution, and general industrial piping. PN25 is used in higher-pressure systems including steam lines and high-temperature fluid handling. PN40 flanges are designed for heavy-duty, high-pressure applications such as chemical processing, power generation, and offshore systems. Selecting the right pressure rating ensures safe, reliable, and efficient operation of piping systems across various industries.

Factors to Consider When Selecting DIN Plate Flange Pressure Ratings:

- Operating Pressure & Temperature: Ensure the flange rating matches the system’s working pressure and temperature to avoid failure or leaks.

- Media Type: Consider the fluid or gas being transported. Corrosive, abrasive, or hazardous substances may require higher-grade materials and pressure ratings.

- Material Compatibility: Choose a flange material that offers adequate resistance to pressure, temperature, and corrosion based on your application.

- Pipe Size & Wall Thickness: Larger pipes or thinner walls may require flanges with higher pressure ratings for added strength and support.

- Environmental Conditions: Take into account exposure to moisture, chemicals, or extreme temperatures that can affect flange performance.

- Compliance & Standards: Verify that the flange meets relevant DIN standards and industry regulations to ensure safety and reliability.

Advantages of Using Properly Rated DIN Plate Flanges:

- Enhanced Safety: Prevents system failures, leaks, and accidents by withstanding designated pressure and temperature levels.

- Longer Service Life: Reduces wear and tear, ensuring durability and minimizing the need for frequent replacements or repairs.

- Improved System Efficiency: Maintains consistent pressure flow, minimizing energy loss and enhancing operational performance.

- Regulatory Compliance: Meets industry standards and safety codes, ensuring project approval and reducing legal risks.

- Cost Savings: Prevents costly downtime, emergency maintenance, and system replacements due to premature flange failure.

- Reliable Sealing: Ensures tight and secure joints for leak-proof connections in high-pressure environments.

Types of DIN PN6 - PN40 Plate Flanges

| Type | Description |

|---|---|

| DIN 2573 PN6 Plate Flanges | Designed for low-pressure systems, these flanges are commonly used in water supply and light-duty industrial pipelines. |

| DIN 2576 PN10 Plate Flanges | Ideal for medium-pressure applications, offering solid leak-proof connections in HVAC and utility piping systems. |

| DIN 2543 PN16 Plate Flanges | These are used in pipelines carrying steam, water, or gas under moderate pressure, widely used across mechanical installations. |

| DIN 2544 PN25 Plate Flanges | Designed for high-pressure fluid handling, these flanges are reliable in demanding environments such as industrial plants. |

| DIN 2545 PN40 Plate Flanges | Made for very high-pressure applications, commonly used in oil & gas, power generation, and heavy-duty mechanical systems. |

DIN PN6 - PN40 Plate Flanges: Dimensions & Pressure Ratings

| Flange Nominal Diameter | Pressure Rating (PN) | |||||

|---|---|---|---|---|---|---|

| Nominal BSP Pipe Size | PN6 | PN10 | PN16 | PN25 | PN40 | Details |

| DN 10 | 75 mm | 90 mm | 90 mm | 90 mm | 90 mm | O.D. |

| 3/8″ | 50 mm | 60 mm | 60 mm | 60 mm | 60 mm | PCD (bolt circle) |

| 4 x 11 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | # of holes x diam. of holes | |

| DN 15 | 80 mm | 95 mm | 95 mm | 95 mm | 95 mm | O.D. |

| 1/2″ | 55 mm | 65 mm | 65 mm | 65 mm | 65 mm | PCD (bolt circle) |

| 4 x 11 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | # of holes x diam. of holes | |

| DN 20 | 90 mm | 105 mm | 105 mm | 105 mm | 105 mm | O.D. |

| 3/4″ | 65 mm | 75 mm | 75 mm | 75 mm | 75 mm | PCD (bolt circle) |

| 4 x 11 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | # of holes x diam. of holes | |

| DN 25 | 100 mm | 115 mm | 115 mm | 115 mm | 115 mm | O.D. |

| 1″ | 75 mm | 85 mm | 85 mm | 85 mm | 85 mm | PCD (bolt circle) |

| 4 x 11 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | # of holes x diam. of holes | |

| DN 32 | 120 mm | 140 mm | 140 mm | 140 mm | 140 mm | O.D. |

| 1 1/4″ | 90 mm | 100 mm | 100 mm | 100 mm | 100 mm | PCD (bolt circle) |

| 4 x 14 mm | 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | # of holes x diam. of holes | |

| DN 40 | 130 mm | 150 mm | 150 mm | 150 mm | 150 mm | O.D. |

| 1 1/2″ | 100 mm | 110 mm | 110 mm | 110 mm | 110 mm | PCD (bolt circle) |

| 4 x 14 mm | 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | # of holes x diam. of holes | |

| DN 50 | 140 mm | 165 mm | 165 mm | 165 mm | 165 mm | O.D. |

| 2″ | 110 mm | 125 mm | 125 mm | 125 mm | 125 mm | PCD (bolt circle) |

| 4 x 14 mm | 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | # of holes x diam. of holes | |

| DN 65 | 160 mm | 185 mm | 185 mm | 185 mm | 185 mm | O.D. |

| 2 1/2″ | 130 mm | 145 mm | 145 mm | 145 mm | 145 mm | PCD (bolt circle) |

| 4 x 14 mm | 4 x 18 mm | 4 x 18 mm | 8 x 18 mm | 8 x 18 mm | # of holes x diam. of holes | |

Industries and Applications of DIN PN6 - PN40 Plate Flanges:

DIN PN6 to PN40 Plate Flanges are widely used across a range of industries due to their versatility, strength, and adaptability to various pressure classes. These flanges are ideal for connecting pipes, valves, pumps, and other equipment, ensuring secure and leak-proof joints in complex piping systems.

- Oil & Gas Industry: Used in upstream, midstream, and downstream operations for safe transportation of crude oil, natural gas, and refined products.

- Petrochemical Plants: Essential in chemical processing systems for high-temperature and corrosive environments.

- Power Generation: Commonly found in steam, gas, and hydroelectric plants for pressure piping and turbine systems.

- Water Treatment Plants: Used in desalination, wastewater, and water distribution networks.

- Pharmaceutical & Food Processing: Suitable for sanitary and sterile environments with specific material grades.

- Marine & Shipbuilding: Applied in ballast, bilge, and fuel systems where reliability and corrosion resistance are critical.

- HVAC & Mechanical Systems: Used in heating, ventilation, and cooling infrastructure for fluid and gas flow control.

Frequently Asked Questions (FAQs) about DIN PN6 - PN40 Plate Flanges

- 1. What are DIN PN6 – PN40 Plate Flanges?

- DIN PN6 to PN40 Plate Flanges are flat, circular flanges manufactured according to DIN standards, designed for bolting directly onto pipe systems operating at varying pressure ratings from 6 to 40 bar.

- 2. What is the difference between PN6, PN10, PN16, PN25, and PN40?

- PN stands for “Pressure Nominale” and indicates the pressure rating of the flange in bars. The higher the PN number, the greater the pressure the flange can handle.

- 3. Where are DIN Plate Flanges typically used?

- They are widely used in pipelines for oil & gas, water treatment, power generation, marine, HVAC, and chemical processing industries.

- 4. Are these flanges suitable for welding?

- No, DIN Plate Flanges are designed for bolting applications and typically used with butt-welded or socket-welded pipe ends, depending on system design.

- 5. Can I use DIN Plate Flanges with ANSI pipes?

- DIN Plate Flanges follow European specifications and may not be directly compatible with ANSI/ASME standards without proper adapters or conversions.

- 6. Do these flanges support high-temperature applications?

- Yes, depending on the material used, DIN Plate Flanges rated PN40 can perform well in high-pressure and high-temperature environments.

- 7. What sizes are available in DIN Plate Flanges?

- DIN PN6 to PN40 Plate Flanges are available in sizes ranging typically from DN15 to DN1000 or larger, depending on the manufacturer.

- 8. How do I choose the correct DIN Plate Flange?

- Selection depends on system pressure, pipe size, operating temperature, and media type. Consult a flange specialist or engineering team for the best fit.

- 9. Are DIN PN Plate Flanges customizable?

- Yes, they can be custom-made in different materials, dimensions, and drilling patterns to meet project-specific requirements.

- 10. Who manufactures high-quality DIN PN6–PN40 Plate Flanges?

- Werner Flanges Inc. is a trusted manufacturer and supplier of DIN PN6 to PN40 Plate Flanges. Contact sales@wernerflanges.com for inquiries or custom orders.