DIN PN6 - PN40 Lapped Flanges

DIN PN6 Lapped Flanges Manufacturer, DIN PN10 Lapped Flanges Stockist, DIN PN16 Lapped Flanges Supplier, DIN PN25 Lapped Flanges Exporter, DIN PN40 Lapped Flanges, DIN Lapped Flanges Supplier in India, Custom DIN Lapped Flanges in Exotic Alloys, Marine-Grade DIN Copper Nickel Lapped Flanges, Stainless Steel DIN Lapped Flanges, Titanium DIN PN25 Lapped Flanges Manufacturer, Duplex Steel DIN PN10 Lapped Flanges Exporter, DIN PN16 Lapped Flanges in Stainless Steel, Hastelloy DIN Lapped Flanges Supplier, Stainless Steel 304 DIN Lapped Flanges Manufacturer in India.

Werner Flanges Inc. specializes in producing high-quality DIN PN6 to PN40 Lapped Flanges that fulfill demanding industry standards and different application requirements. Our DIN lapped flanges are very durable and precise, making them suitable for pipe systems requiring simple installation and disassembly, particularly in the petrochemical, maritime, power generation, and pharmaceutical sectors. Our lapped flanges, made from premium materials such as stainless steel, exotic alloys, and marine-grade copper nickel, provide exceptional corrosion resistance and dependable performance under pressure ratings ranging from PN6 to PN40.

Werner Flanges Inc. understands the value of unique solutions suited to your project’s needs. Whether you require conventional DIN lapped flanges or bespoke sizes and materials, our skilled staff is ready to provide high-quality goods on time. Our reliable lapping flanges will increase the flexibility and maintenance efficiency of your pipe system. For further information, pricing, or bespoke orders, please contact us at sales@wernerflanges.com. We have the experience and commitment to meet your industrial flange demands.

SS 316 DIN PN6 Lapped Flanges, Carbon Steel DIN Lapped Flanges, Duplex Steel S31803 DIN Lapped Flanges, Super Duplex S32750 DIN Lapped Flanges, Titanium DIN Lapped Flanges, Copper Nickel DIN Lapped Flanges, CuNi DIN PN16 Lapped Flanges, Inconel DIN PN40 Lapped Flanges, Monel DIN PN6 Lapped Flanges, DIN PN40 Lapped Flanges for High Pressure Applications, Nickel Alloy DIN PN40 Lapped Flanges for Heat Exchangers, Carbon Steel DIN PN6 Lapped Flanges for Water Pipelines, DIN Lapped Flanges Price, DIN PN10 Lapped Flanges Ready Stock, DIN Lapped Flanges for Oil & Gas, DIN Lapped Flanges for Petrochemical Applications.

DIN PN6 - PN40 Lapped Flanges Technical Specifications

| Specification | Details |

|---|---|

| Standards | DIN EN 1092-1 (replaces older DIN standards like DIN 2565, DIN 2566) |

| Pressure Ratings (PN) | PN6, PN10, PN16, PN25, PN40 |

| Flange Type | Lapped Flanges (Loose Flanges) |

| Size Range | DN 10 to DN 600 (custom sizes available on request) |

| Face Types | Raised Face (RF), Flat Face (FF) |

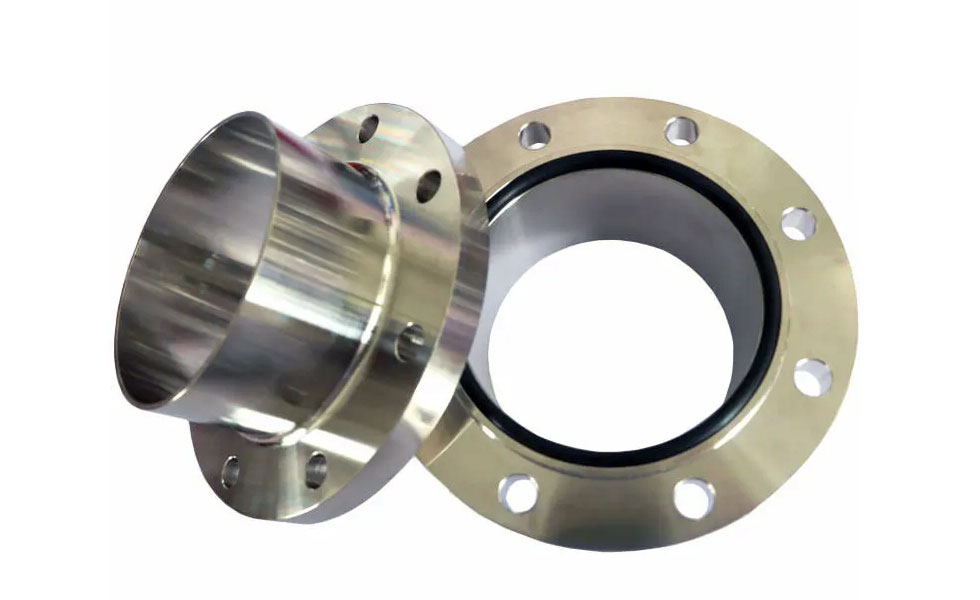

| Connection | Used with stub end fittings; allows easy alignment and removal without welding |

| Material Compatibility | Compatible with various materials including carbon steel, stainless steel, duplex, and exotic alloys |

| Dimensions | In accordance with DIN EN 1092-1 specifications |

| Testing | Hydrostatic pressure testing, dimensional inspection, and surface finish verification |

| Surface Finish | Precision machined surface for proper sealing and fit with stub ends |

DIN PN6 – PN40 Lapped Flanges Technical Specifications

Material Specifications for DIN PN6 - PN40 Lapped Flanges

| Type of Materials | Common Specifications / Customization Available on Request * Materials conform to ASTM/ASME standards and are compatible with DIN PN6 – PN40 Lapped Flanges |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347, F904L, etc. |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Understanding Pressure Ratings in DIN Lapped Flanges:

Understanding Pressure Ratings in DIN Lapped Flanges is critical for selecting the appropriate flange for your pipe system, ensuring safety and dependability. Pressure ratings, abbreviated as PN (Pressure Nominal), categorize flanges according to the highest pressure they can safely sustain at a particular temperature. DIN lapped flanges are often rated with PN6, PN10, PN16, PN25, and PN40, which correspond to pressure capabilities ranging from 6 to 40 bar. Choosing a flange with the suitable PN rating is critical for managing the system’s working pressure and preventing leaks or failures, particularly in demanding sectors like as oil and gas, petrochemicals, and water treatment.

Werner Flanges Inc. provides high-quality DIN PN6 to PN40 lapped flanges that are constructed to exacting DIN EN 1092-1 requirements, assuring precision and longevity. Our lapped flanges are intended to function smoothly with stub ends, allowing for easy installation and maintenance without welding. Whether you need flanges for low-pressure water pipes or high-pressure industrial applications, our knowledgeable staff can advise you on the best PN rating and material choice. For queries or bespoke orders, please contact us at sales@wernerflanges.com.

Factors to Consider When Selecting DIN Lapped Flange Pressure Ratings:

- Operating Pressure and Temperature: Ensure the flange’s PN rating matches or exceeds the maximum pressure and temperature conditions of your system for safe operation.

- Type of Fluid: Consider the chemical nature of the fluid being transported—corrosive or abrasive fluids may require specialized flange materials or coatings.

- Material Compatibility: Select flange materials compatible with the connected piping and stub ends to prevent galvanic corrosion and ensure mechanical integrity.

- System Application: High-pressure systems, heat exchangers, or critical process lines may require higher PN ratings and specific flange designs.

- Standards Compliance: Choose flanges manufactured as per DIN EN 1092-1 to ensure dimensional accuracy and pressure performance.

- Installation Requirements: Consider ease of installation and whether the flange requires threading, welding, or other joining methods.

At Werner Flanges Inc., we offer a wide range of DIN lapped flanges from PN6 to PN40, tailored to your specific industry needs. Contact us at sales@wernerflanges.com for expert advice and customized solutions.

Advantages of Using Properly Rated DIN Lapped Flanges:

- Enhanced Safety: Properly rated DIN lapped flanges ensure the flange can withstand the system’s operating pressure, minimizing the risk of leaks or failures.

- Reliable Sealing: Accurate pressure rating guarantees a tight and secure seal between the flange and the piping system, preventing fluid loss and contamination.

- Extended Service Life: Using flanges with the correct PN rating reduces stress and wear, enhancing durability and reducing maintenance frequency.

- Cost Efficiency: Selecting the right flange rating avoids over-specification and unnecessary expenses while ensuring performance and safety.

- Compliance with Standards: Properly rated flanges comply with DIN EN 1092-1 standards, ensuring compatibility and quality assurance across systems.

- Versatility: DIN lapped flanges come in multiple PN ratings, allowing precise selection for diverse industrial applications, from low to high pressure.

Trust Werner Flanges Inc. for high-quality DIN lapped flanges that meet your exact pressure requirements. Reach out at sales@wernerflanges.com for expert support and orders.

Types of DIN PN6 - PN40 Lapped Flanges

| Type | Description |

|---|---|

| DIN PN6 Lapped Flanges | Best suited for low-pressure applications such as water pipelines, HVAC systems, and non-critical fluid transport where ease of installation and maintenance is essential. |

| DIN PN10 Lapped Flanges | Used in medium-duty operations like compressed air systems, fire protection lines, and low-pressure industrial processes, offering a reliable connection with easy alignment. |

| DIN PN16 Lapped Flanges | Ideal for applications in industrial water lines, moderate gas supply networks, and general chemical processing where higher pressure handling is required. |

| DIN PN25 Lapped Flanges | Engineered for high-pressure piping in steam systems, refinery processes, and mechanical plants, providing secure, leak-proof joints with superior strength. |

| DIN PN40 Lapped Flanges | Recommended for extremely high-pressure environments such as offshore platforms, oil & gas pipelines, and heat exchanger systems where mechanical strength and pressure integrity are critical. |

DIN PN6 - PN40 Lapped Flanges: Dimensions & Pressure Ratings

| Nominal Size (DN) | Outside Diameter (OD) (mm) | Bolt Circle Diameter (PCD) (mm) | Number of Bolt Holes | Bolt Hole Diameter (mm) | Flange Thickness (mm) | Pressure Rating (PN) |

|---|---|---|---|---|---|---|

| DN 15 / 1/2″ | 95 (PN6), 105 (PN10-40) | 65 | 4 | 14 | 14 (PN6), 16 (PN10-40) | PN6, PN10, PN16, PN25, PN40 |

| DN 20 / 3/4″ | 105 (PN6), 115 (PN10-40) | 75 | 4 | 14 | 14 (PN6), 16 (PN10-40) | PN6, PN10, PN16, PN25, PN40 |

| DN 25 / 1″ | 115 (PN6), 130 (PN10-40) | 85 | 4 | 14 | 14 (PN6), 16 (PN10-40) | PN6, PN10, PN16, PN25, PN40 |

| DN 32 / 1 1/4″ | 140 (PN6), 150 (PN10-40) | 100 | 4 | 14 | 16 (PN6), 18 (PN10-40) | PN6, PN10, PN16, PN25, PN40 |

| DN 40 / 1 1/2″ | 150 (PN6), 160 (PN10-40) | 110 | 4 | 18 | 16 (PN6), 18 (PN10-40) | PN6, PN10, PN16, PN25, PN40 |

| DN 50 / 2″ | 165 (PN6), 180 (PN10-40) | 125 | 4 | 18 | 16 (PN6), 20 (PN10-40) | PN6, PN10, PN16, PN25, PN40 |

| DN 65 / 2 1/2″ | 190 (PN6), 215 (PN10-40) | 145 | 4 | 18 | 18 (PN6), 22 (PN10-40) | PN6, PN10, PN16, PN25, PN40 |

| DN 80 / 3″ | 210 (PN6), 240 (PN10-40) | 160 | 8 | 18 | 20 (PN6), 24 (PN10-40) | PN6, PN10, PN16, PN25, PN40 |

| DN 100 / 4″ | 240 (PN6), 285 (PN10-40) | 180 | 8 | 18 | 20 (PN6), 24 (PN10-40) | PN6, PN10, PN16, PN25, PN40 |

| DN 125 / 5″ | 270 (PN6), 320 (PN10-40) | 210 | 8 | 18 | 22 (PN6), 26 (PN10-40) | PN6, PN10, PN16, PN25, PN40 |

| DN 150 / 6″ | 300 (PN6), 350 (PN10-40) | 240 | 8 | 22 | 24 (PN6), 28 (PN10-40) | PN6, PN10, PN16, PN25, PN40 |

| DN 200 / 8″ | 360 (PN6), 405 (PN10-40) | 295 | 8 | 22 | 26 (PN6), 30 (PN10-40) | PN6, PN10, PN16, PN25, PN40 |

| DN 250 / 10″ | 430 (PN6), 480 (PN10-40) | 350 | 12 | 26 | 28 (PN6), 32 (PN10-40) | PN6, PN10, PN16, PN25, PN40 |

| DN 300 / 12″ | 485 (PN6), 535 (PN10-40) | 400 | 12 | 26 | 30 (PN6), 34 (PN10-40) | PN6, PN10, PN16, PN25, PN40 |

Industries and Applications of DIN PN6 - PN40 Lapped Flanges:

- Petrochemical & Refining: Used in process piping systems requiring regular maintenance or inspection, especially for low-pressure fuel, solvent, and hydrocarbon lines.

- Oil & Gas Industry: Ideal for onshore and offshore pipelines where easy assembly/disassembly is needed; commonly used in low-pressure gas transmission and flare systems.

- Chemical & Fertilizer Plants: Suitable for handling corrosive chemicals in non-critical service lines; often paired with corrosion-resistant alloys for extended life.

- Water Treatment & Wastewater Management: Widely used in potable water, effluent, and desalination pipelines due to ease of maintenance and corrosion resistance.

- Power Generation: Applied in auxiliary systems of thermal and hydroelectric power plants, especially in low-pressure steam and cooling water circuits.

- Pharmaceuticals & Food Processing: Preferred for sanitary piping systems that require frequent dismantling and cleaning, typically made from stainless steel for hygiene.

- Marine & Shipbuilding: Installed in systems such as ballast, bilge, and cooling water due to the flange’s ability to accommodate confined installation spaces.

- HVAC & Building Services: Utilized in chilled water, hot water, and compressed air pipelines where easy future maintenance or expansion is necessary.

- Pulp & Paper Industry: Used in processing systems for paper production, handling low-pressure steam and chemicals with minimal downtime.

Frequently Asked Questions (FAQs) about DIN PN6 - PN40 Threaded Flanges

- 1. What are DIN PN6 – PN40 Lapped Flanges?

- DIN PN6 to PN40 Lapped Flanges are flanges used with stub ends, allowing for rotation and easy alignment. They are designed as per DIN standards to handle pressure ratings from 6 to 40 bar.

- 2. In which industries are DIN PN6 – PN40 Lapped Flanges commonly used?

- They are commonly used in industries such as oil & gas, chemical processing, pharmaceuticals, water treatment, food & beverage, and shipbuilding.

- 3. What materials are typically used to manufacture these lapped flanges?

- Lapped flanges are often manufactured from stainless steel, carbon steel, and alloy steels depending on the application and environment.

- 4. What are the benefits of using lapped flanges?

- Lapped flanges allow for easy bolt alignment, reduce warping and stress in the flange face, and are reusable, making them ideal for systems that require frequent disassembly.

- 5. Can DIN Lapped Flanges be used for high-temperature applications?

- Yes, when paired with suitable materials and stub ends, they can be used for high-temperature applications depending on the PN rating.

- 6. Are DIN lapped flanges compatible with ANSI flanges?

- No, DIN and ANSI standards differ in dimensions and pressure ratings. Adapters or transition flanges are required for compatibility.

- 7. How do I choose the correct PN rating for my application?

- Select the PN rating that meets or exceeds the maximum pressure and temperature requirements of your pipeline system.

- 8. What standards govern DIN PN6 – PN40 Lapped Flanges?

- DIN EN 1092-1 is the key standard that defines the dimensions and pressure classes for DIN lapped flanges.

- 9. Can I order custom-sized or special material lapped flanges?

- Yes, manufacturers often offer custom sizes, materials, and finishes to meet specific project requirements.

- 10. Where can I buy high-quality DIN PN6 – PN40 Lapped Flanges?

- Contact trusted suppliers or manufacturers such as Werner Flanges Inc. at sales@wernerflanges.com for quotes and product availability.