DIN PN6 - PN40 Blind Flanges

DIN PN6 Blind Flanges Manufacturer, DIN PN10 Blind Flanges Stockist, DIN PN16 Blind Flanges Supplier, DIN PN25 Blind Flanges Exporter, DIN PN40 Blind Flanges, DIN Blind Flanges Supplier in India, Custom DIN Blind Flanges in Exotic Alloys, Marine-Grade DIN Copper Nickel Blind Flanges, Stainless Steel DIN Blind Flanges, Titanium DIN PN25 Blind Flanges Manufacturer, Duplex Steel DIN PN10 Blind Flanges Exporter, DIN PN16 Blind Flanges in Stainless Steel, Hastelloy DIN Blind Flanges Supplier, Stainless Steel 304 DIN Blind Flanges Manufacturer in India

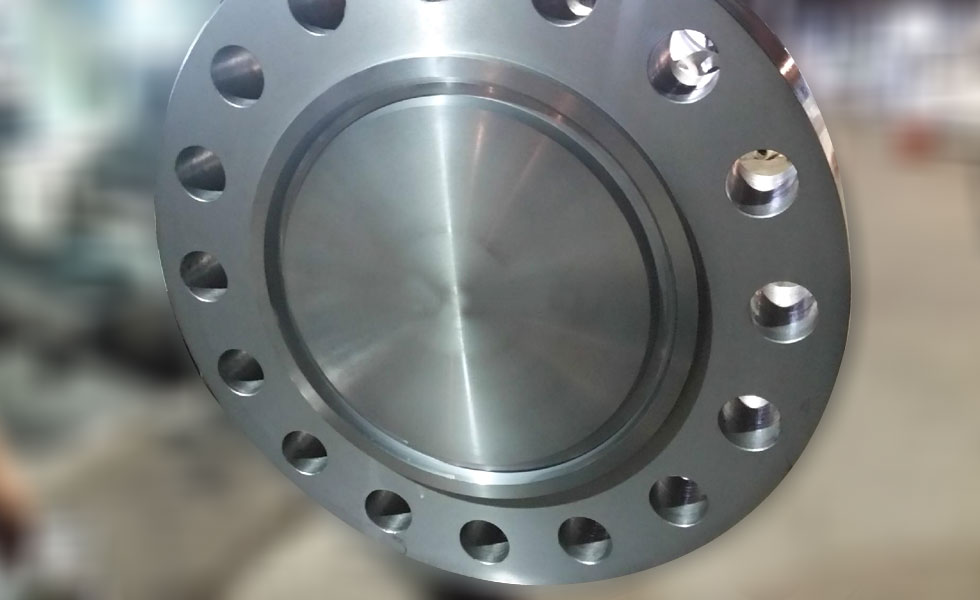

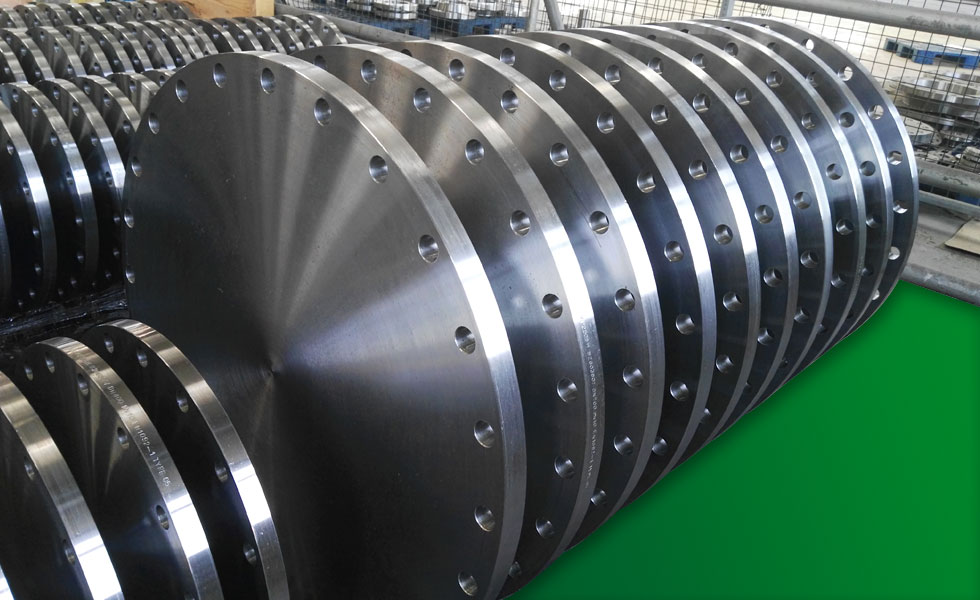

Werner Flanges Inc. is an established manufacturer and exporter of high-quality DIN PN6 to PN40 Blind Flanges, developed to provide secure sealing solutions for pipe systems in a variety of sectors. These blind flanges are designed to resist pressure levels ranging from 6 to 40 bar, making them suitable for separating pipelines, valves, and equipment during maintenance or system shutdowns. Our DIN blind flanges are made from premium materials such as stainless steel, carbon steel, duplex, super duplex, and exotic alloys, ensuring durability, corrosion resistance, and dependable performance in demanding situations such as oil and gas, petrochemical, water treatment, and power generation.

Werner Flanges Inc. understands the importance of accurate specifications and timely delivery. Our skilled staff guarantees that each blind flange fulfills high quality standards and is tailored to your specific project requirements. Whether you need stock-size or custom-engineered DIN PN blind flanges, we are here to help with experienced advice and low prices. Contact us now at sales@wernerflanges.com to request a quotation or learn more about our extensive selection of DIN PN6 – PN40 Blind Flanges and how they may improve the safety and efficiency of your plumbing system.

SS 316 DIN PN6 Blind Flanges, Carbon Steel DIN Blind Flanges, Duplex Steel S31803 DIN Blind Flanges, Super Duplex S32750 DIN Blind Flanges, Titanium DIN Blind Flanges, Copper Nickel DIN Blind Flanges, CuNi DIN PN16 Blind Flanges, Inconel DIN PN40 Blind Flanges, Monel DIN PN6 Blind Flanges, DIN PN40 Blind Flanges for High Pressure Applications, Nickel Alloy DIN PN40 Blind Flanges for Heat Exchangers, Carbon Steel DIN PN6 Blind Flanges for Water Pipelines, DIN Blind Flanges Price, DIN PN10 Blind Flanges Ready Stock, DIN Blind Flanges for Oil & Gas, DIN Blind Flanges for Petrochemical Applications.

DIN PN6 - PN40 Blind Flanges Technical Specifications

| Specification | Details |

|---|---|

| Standards | DIN EN 1092-1 (formerly DIN 2633, DIN 2634, DIN 2635, DIN 2636) |

| Pressure Ratings (PN) | PN6, PN10, PN16, PN25, PN40 |

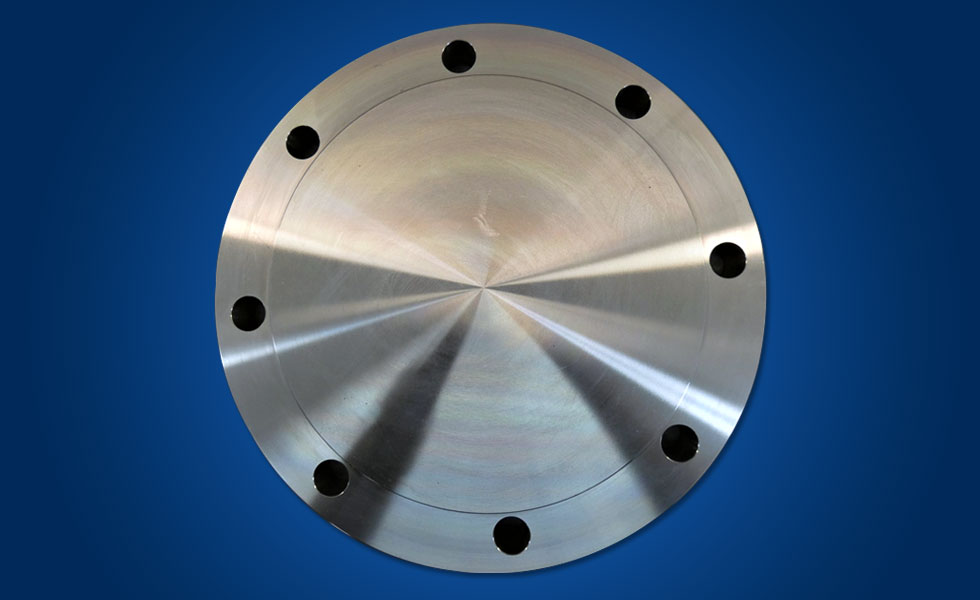

| Flange Type | Blind Flanges |

| Size Range | DN 10 to DN 600 (or as per customer requirement) |

| Face Types | Raised Face (RF), Flat Face (FF), Tongue and Groove (T&G) |

| Connection | Used to close or seal pipe ends or valves |

| Dimensions | According to DIN EN 1092-1 specifications |

| Testing | Hydrostatic test, Radiographic test, Dimensional inspection |

| Surface Finish | Machined with high precision for a smooth sealing surface |

Material Specifications for DIN PN6 - PN40 Blind Flanges

| Type of Materials | Common Specifications / Customization Available on Request * Materials conform to ASTM/ASME standards and are compatible with DIN PN6 – PN40 Blind Flanges |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347, F904L, etc. |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Understanding Pressure Ratings in DIN Blind Flanges:

DIN Blind Flanges are engineered to withstand specific pressure ratings, commonly denoted as PN (Pressure Nominale) values such as PN6, PN10, PN16, PN25, and PN40. These pressure ratings indicate the maximum allowable operating pressure the flange can safely handle at a given temperature, ensuring system integrity and safety. Selecting the correct PN rating is critical to match the operational demands of your piping system, preventing leaks, failures, and costly downtime. Higher PN numbers correspond to flanges capable of withstanding greater pressures, making PN40 suitable for high-pressure applications like petrochemical or power plants, while PN6 or PN10 are typically used for low to moderate pressure systems.

Factors to Consider When Selecting DIN Blind Flange Pressure Ratings:

- Operating Pressure: Ensure the flange pressure rating (PN) matches or exceeds the system’s maximum operating pressure.

- Temperature Conditions: Consider the operating temperature, as pressure ratings can vary with temperature fluctuations.

- Material Compatibility: Select flange materials that can withstand the chemical and physical properties of the media.

- Application Environment: Account for environmental factors such as corrosion, abrasion, and exposure to chemicals.

- Industry Standards: Follow applicable industry codes and standards to ensure safety and regulatory compliance.

- System Design Requirements: Take into account pipe size, connection type, and installation space.

- Future Expansion: Consider potential system upgrades or increased pressure demands when selecting ratings.

Advantages of Using Properly Rated DIN Blind Flanges:

- Enhanced Safety: Proper pressure ratings ensure flanges can safely withstand system pressures, reducing risk of leaks or failures.

- Improved Durability: Flanges rated correctly for pressure last longer, minimizing wear and tear in demanding environments.

- Better Performance: Maintains system integrity by providing reliable sealing and preventing pressure loss.

- Regulatory Compliance: Meets industry standards and legal requirements, ensuring safe operation and avoiding penalties.

- Cost Efficiency: Reduces maintenance and replacement costs by using flanges suited for specific pressure conditions.

- Versatility: Available in multiple pressure classes, allowing precise selection for varied industrial applications.

- Peace of Mind: Confidence in system reliability when using flanges with correct pressure ratings.

Types of DIN PN6 - PN40 Blind Flanges

| Type | Description |

|---|---|

| DIN 2527 PN6 Blind Flanges | Used in low-pressure systems such as water supply lines, HVAC, and general plumbing. Ideal for closing pipe ends securely without pressure build-up. |

| DIN 2527 PN10 Blind Flanges | Suited for moderate pressure applications including irrigation, compressed air systems, and low-pressure industrial processes. |

| DIN 2527 PN16 Blind Flanges | Commonly used in industrial water systems, gas lines, and chemical processing plants, offering a secure seal under medium pressure. |

| DIN 2527 PN25 Blind Flanges | Reliable in high-pressure environments such as steam piping, refineries, and power plant applications where robust sealing is required. |

| DIN 2527 PN40 Blind Flanges | Designed for very high-pressure systems in oil & gas, petrochemical, and offshore installations, ensuring leak-proof performance and safety. |

DIN PN6 - PN40 Blind Flanges: Dimensions & Pressure Ratings

| Nominal Size | PN6 O.D. | PN10 O.D. | PN16 O.D. | PN25 O.D. | PN40 O.D. | Dimension Type |

|---|---|---|---|---|---|---|

| DN 15 / 1/2″ | 95 mm | 105 mm | 105 mm | 105 mm | 105 mm | O.D. |

| 65 mm | 65 mm | 65 mm | 65 mm | 65 mm | PCD | |

| 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | Holes x diameter | |

| DN 20 / 3/4″ | 105 mm | 115 mm | 115 mm | 115 mm | 115 mm | O.D. |

| 75 mm | 75 mm | 75 mm | 75 mm | 75 mm | PCD | |

| 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | Holes x diameter | |

| DN 25 / 1″ | 115 mm | 130 mm | 130 mm | 130 mm | 130 mm | O.D. |

| 85 mm | 85 mm | 85 mm | 85 mm | 85 mm | PCD | |

| 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | Holes x diameter | |

| DN 32 / 1 1/4″ | 140 mm | 150 mm | 150 mm | 150 mm | 150 mm | O.D. |

| 100 mm | 100 mm | 100 mm | 100 mm | 100 mm | PCD | |

| 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | 4 x 14 mm | Holes x diameter | |

| DN 40 / 1 1/2″ | 150 mm | 160 mm | 160 mm | 160 mm | 160 mm | O.D. |

| 110 mm | 110 mm | 110 mm | 110 mm | 110 mm | PCD | |

| 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | Holes x diameter | |

| DN 50 / 2″ | 165 mm | 180 mm | 180 mm | 180 mm | 180 mm | O.D. |

| 125 mm | 125 mm | 125 mm | 125 mm | 125 mm | PCD | |

| 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | Holes x diameter | |

| DN 65 / 2 1/2″ | 190 mm | 215 mm | 215 mm | 215 mm | 215 mm | O.D. |

| 180 mm | 180 mm | 180 mm | 180 mm | 180 mm | PCD | |

| 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | Holes x diameter | |

| DN 80 / 3″ | 210 mm | 240 mm | 240 mm | 240 mm | 240 mm | O.D. |

| 195 mm | 195 mm | 195 mm | 195 mm | 195 mm | PCD | |

| 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | 4 x 18 mm | Holes x diameter | |

| DN 100 / 4″ | 240 mm | 285 mm | 285 mm | 285 mm | 285 mm | O.D. |

| 215 mm | 215 mm | 215 mm | 215 mm | 215 mm | PCD | |

| 8 x 18 mm | 8 x 18 mm | 8 x 18 mm | 8 x 18 mm | 8 x 18 mm | Holes x diameter | |

| DN 125 / 5″ | 270 mm | 320 mm | 320 mm | 320 mm | 320 mm | O.D. |

| 250 mm | 250 mm | 250 mm | 250 mm | 250 mm | PCD | |

| 8 x 18 mm | 8 x 18 mm | 8 x 18 mm | 8 x 18 mm | 8 x 18 mm | Holes x diameter | |

| DN 150 / 6″ | 300 mm | 350 mm | 350 mm | 350 mm | 350 mm | O.D. |

| 280 mm | 280 mm | 280 mm | 280 mm | 280 mm | PCD | |

| 8 x 22 mm | 8 x 22 mm | 8 x 22 mm | 8 x 22 mm | 8 x 22 mm | Holes x diameter | |

| DN 200 / 8″ | 360 mm | 405 mm | 405 mm | 405 mm | 405 mm | O.D. |

| 335 mm | 335 mm | 335 mm | 335 mm | 335 mm | PCD | |

| 8 x 22 mm | 8 x 22 mm | 8 x 22 mm | 8 x 22 mm | 8 x 22 mm | Holes x diameter | |

| DN 250 / 10″ | 430 mm | 480 mm | 480 mm | 480 mm | 480 mm | O.D. |

| 395 mm | 395 mm | 395 mm | 395 mm | 395 mm | PCD | |

| 12 x 26 mm | 12 x 26 mm | 12 x 26 mm | 12 x 26 mm | 12 x 26 mm | Holes x diameter | |

| DN 300 / 12″ | 485 mm | 535 mm | 535 mm | 535 mm | 535 mm | O.D. |

| 460 mm | 460 mm | 460 mm | 460 mm | 460 mm | PCD | |

| 12 x 26 mm | 12 x 26 mm | 12 x 26 mm | 12 x 26 mm | 12 x 26 mm | Holes x diameter |

Industries and Applications of DIN PN6 - PN40 Blind Flanges:

DIN PN6 to PN40 Blind Flanges are essential components widely used in various industries for securely closing the ends of pipelines, valves, and pressure vessels. These flanges offer strong, leak-proof sealing to ensure safety and system integrity in high-pressure and demanding environments.

- Oil & Gas Industry: Used in pipelines, refineries, and offshore platforms to isolate sections for maintenance and prevent leaks in crude oil and natural gas transport.

- Chemical & Petrochemical Plants: Critical for safely sealing piping systems that handle corrosive and high-temperature fluids during chemical processing.

- Power Generation: Applied in steam, gas, and nuclear power plants for closing pressure pipelines and equipment during operation and maintenance.

- Water Treatment & Distribution: Used in municipal water supply, sewage, and irrigation pipelines to close ends securely under various pressure conditions.

- Pharmaceutical & Food Processing: Suitable for hygienic and sterile piping systems requiring contamination-free closure points.

- Marine & Shipbuilding: Employed in ship piping systems like ballast, bilge, and fuel lines requiring durable, corrosion-resistant closures.

- Industrial Manufacturing: Used in various manufacturing plants to isolate piping sections during repairs, testing, or system upgrades.

Frequently Asked Questions (FAQs) about DIN PN6 - PN40 Blind Flanges

- 1. What are DIN PN6 – PN40 Blind Flanges?

- DIN PN6 to PN40 Blind Flanges are solid flanges used to close pipe ends or valves, designed according to DIN standards with pressure ratings from 6 to 40 bar, ensuring a leak-proof seal and easy system isolation.

- 2. What industries commonly use DIN PN6 – PN40 Blind Flanges?

- These flanges are commonly used in oil & gas, petrochemical, power generation, water treatment, marine, pharmaceutical, and HVAC industries.

- 3. What materials are typically used for these blind flanges?

- Common materials include carbon steel, stainless steel, alloy steel, and special alloys that offer corrosion resistance and high-temperature durability.

- 4. How do I select the appropriate PN rating for my application?

- Choose a flange with a PN rating that meets or exceeds the system’s maximum operating pressure and temperature to ensure safety and optimal performance.

- 5. What are the advantages of using blind flanges?

- Blind flanges provide a secure seal to close pipe ends, facilitate easy maintenance and inspection, and help isolate sections of piping systems safely.

- 6. Can DIN PN blind flanges be interchanged with ANSI flanges?

- No, DIN PN and ANSI flanges have different dimensions and bolt patterns and are generally not interchangeable without adapters.

- 7. How does flange thickness vary with PN rating?

- Flange thickness typically increases with higher PN ratings to withstand greater pressure levels and maintain mechanical integrity.

- 8. Which standards govern DIN PN6 – PN40 Blind Flanges?

- DIN EN 1092-1 is the main standard governing flange dimensions and pressure classes, with material specifications defined separately.

- 9. Are custom sizes and materials available?

- Yes, many manufacturers offer custom flange sizes, materials, and drilling patterns to suit specific project needs.

- 10. Where can I purchase high-quality DIN PN6 – PN40 Blind Flanges?

- Contact trusted suppliers or manufacturers such as Werner Flanges Inc. at sales@wernerflanges.com for inquiries and custom orders.