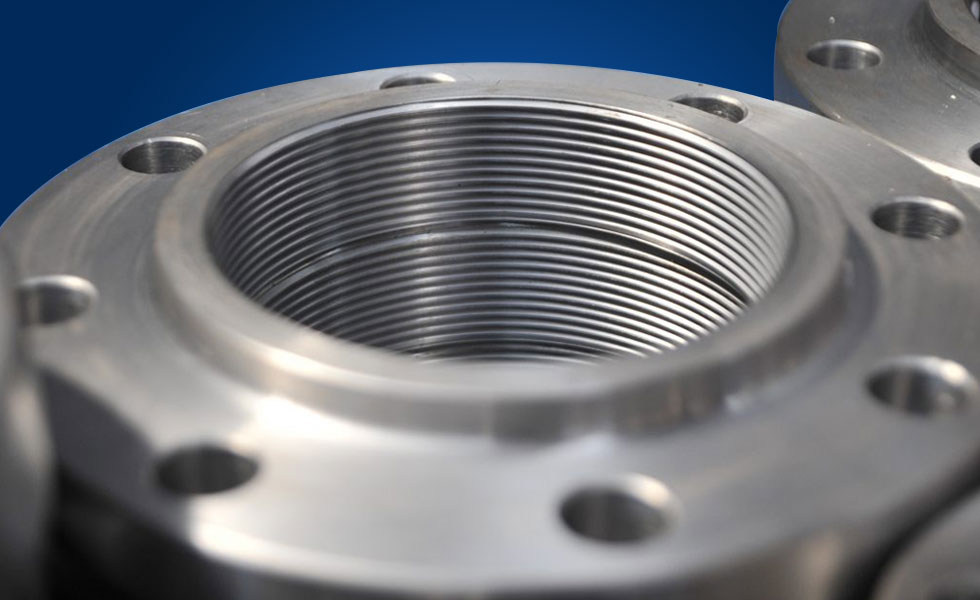

BS 10 Table E Flanges

Manufacturer and Supplier of BS 10 Table E Flanges in Various Material Grades and Types. BS 10 Table E Flanges Manufacturer in Mumbai, India. We supply a complete range of BS 10 Table E Slip-On Flanges, Weld Neck Flanges, Blind Flanges, Threaded Flanges, and Lap Joint Flanges in accordance with BS 10 standard specifications.

Carbon Steel BS 10 Table E Slip-On Flanges Supplier, Stainless Steel BS 10 Table E Weld Neck Flanges Exporter, Alloy Steel BS 10 Table E Blind Flanges Stockist, Copper Nickel BS 10 Table E Threaded Flanges Distributor, Inconel BS 10 Table E Lap Joint Flanges Manufacturer, Monel BS 10 Table E Flanges, Hastelloy BS 10 Table E Flanges, Titanium BS 10 Table E Flanges, and Duplex Steel BS 10 Table E Flanges Manufacturer & Exporter in Mumbai, India.

BS 10 Table E Flanges are widely used in low-to-medium pressure piping systems across industries such as waterworks, HVAC, fire protection, and shipbuilding. Manufactured in accordance with the British Standard BS 10, these flanges are designed to suit applications up to 600 psi, depending on the material and type. At Werner Flanges Inc., we offer a comprehensive range of BS 10 Table E Flanges including Slip-On, Weld Neck, Blind, Threaded, and Lap Joint flanges, all crafted from high-quality materials such as Carbon Steel, Stainless Steel, Duplex Steel, Monel, Inconel, Hastelloy, and more.

Our BS 10 Table E Flanges are available in sizes ranging from ½” to 36”, with surface finishes and drilling patterns compliant with international norms. Whether you need flanges for water pipelines, desalination projects, or industrial process lines, Werner Flanges Inc. delivers superior quality with prompt service and global export capabilities. For custom requirements or large-scale orders, reach out to our sales team at sales@wernerflanges.com.

Stainless Steel 316 BS 10 Table E Flanges, Carbon Steel BS 10 Table E Slip-On Flanges, Duplex Steel S31803 BS 10 Table E Weld Neck Flanges, Super Duplex S32750 BS 10 Table E Blind Flanges, Titanium BS 10 Table E Flanges, Copper Nickel BS 10 Table E Threaded Flanges, CuNi BS 10 Table E Lap Joint Flanges, Inconel BS 10 Table E Weld Neck Flanges, Monel BS 10 Table E Slip-On Flanges, BS 10 Table E Flanges for Medium Pressure Water & Steam Systems, Nickel Alloy BS 10 Table E Flanges for Oil & Chemical Process Plants, Carbon Steel BS 10 Table E Flanges for Utility and Pipeline Systems, BS 10 Table E Flanges Available at Competitive Prices, BS 10 Table E Flanges Ready Stock in Mumbai, India, BS 10 Table E Flanges for Petroleum and Gas Industries, BS 10 Table E Flanges for Marine, HVAC, and Power Generation Applications.

BS 10 Table E Flanges Technical Specifications

| Specification | Details |

|---|---|

| Standard | BS 10 – British Standard Specification for Flanges |

| Table Designation | Table E |

| Flange Types | Slip-On, Weld Neck, Blind, Threaded, Lap Joint |

| Pressure Rating | Up to ~600 psi (depending on material and size) |

| Size Range | ½” to 36” (DN 15 to DN 900) |

| Facing Type | Raised Face (RF), Flat Face (FF) |

| Drilling | As per BS 10 Table E |

| Testing & Certification | EN 10204 3.1 / 3.2, NACE MR0175, IBR, PED, etc. |

Material Specifications for BS 10 Table E Flanges

| Type of Materials | Common Specifications / Customization Available on Request * Materials conform to ASTM/ASME standards and are compatible with BS 10 Table E Flanges |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347 |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Types of BS 10 Table E Flanges

- BS 10 Table E Slip-On Flanges

- BS 10 Table E Weld Neck Flanges

- BS 10 Table E Blind Flanges

- BS 10 Table E Threaded Flanges

- BS 10 Table E Lap Joint Flanges

Industries and Applications of BS 10 Table E Flanges:

| Industry | Application |

|---|---|

| Water Treatment | Used in water supply lines and distribution systems |

| Fire Protection | Employed in fire sprinkler and hydrant networks |

| HVAC | Flanges in air handling units, cooling systems, and ducts |

| Shipbuilding & Marine | Used in seawater, fuel, and ballast systems |

| Oil & Gas | Installed in pipelines and storage facilities |

| Chemical Industry | For low-to-medium pressure corrosive media handling |

| Power Generation | Used in low-pressure steam and utility piping |

Frequently Asked Questions (FAQs) about BS 10 Table E Flanges

- 1. What is BS 10 Table E?

- BS 10 Table E is a British flange standard that specifies dimensions and pressure ratings suitable for moderate-pressure applications, often up to 600 psi depending on the flange size and material.

- 2. What materials are BS 10 Table E Flanges made from?

- These flanges are available in carbon steel, stainless steel, alloy steel, copper nickel, Inconel, Monel, and other high-performance alloys.

- 3. Are BS 10 Table E Flanges suitable for seawater applications?

- Yes, when manufactured using corrosion-resistant materials like Copper Nickel or Duplex Steel, these flanges are ideal for seawater service.

- 4. Can I use BS 10 Table E Flanges for high-pressure pipelines?

- They are best suited for low to medium-pressure pipelines. For higher pressure, BS 10 Table F or ANSI flanges may be more appropriate.

- 5. What sizes are available in BS 10 Table E Flanges?

- Flanges are typically available from ½” (DN 15) up to 36” (DN 900), with custom sizes available upon request.