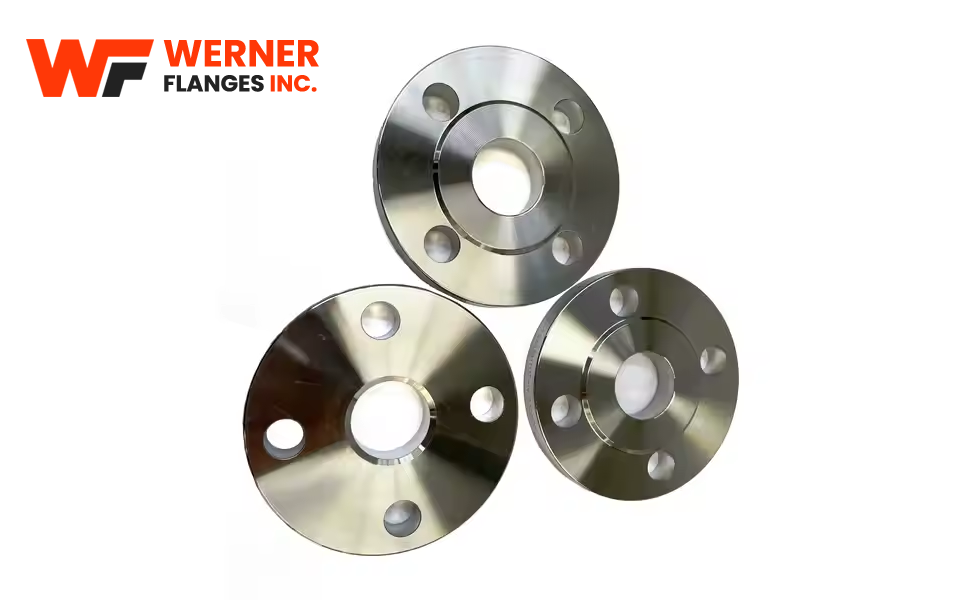

AWWA C207 Class D Ring Flanges for High-Pressure Water Systems

The AWWA C207 Class D Ring Flange is a robust and versatile flange used primarily in high-pressure waterworks systems. Designed as a flat-faced ring flange, it conforms to the AWWA C207 standard and is typically drilled to ANSI B16.5 Class 150 dimensions. With a working pressure capacity of up to 275 psi (for smaller sizes), this flange offers an excellent solution for critical service applications in municipal and industrial pipeline systems. Werner Flanges Inc. manufactures and supplies precision-machined Class D flanges using premium carbon steel materials and certified processes.

AWWA Class D flanges are suitable for applications involving elevated pressure requirements, including potable water systems, wastewater treatment, industrial process piping, and infrastructure requiring heavy-duty flanging. Their ability to perform in demanding environments makes them a preferred choice for water utilities, government projects, and large-scale engineering contracts.

Werner Flanges Inc. offers AWWA C207 Class D Ring Flanges in a wide range of sizes from 4 inches to 144 inches. These flanges are available in standard carbon steel with optional protective coatings such as black paint, red oxide primer, or hot-dip galvanizing. Our offerings include both undrilled and ANSI-drilled flanges to suit different installation requirements. With a strong global supply chain and large stock volumes, we support urgent procurement needs across industries.

With decades of industry experience, Werner Flanges Inc. is a trusted source for AWWA flanges worldwide. We emphasize quality control, dimensional accuracy, and timely delivery. Our flanges are backed by mill test certificates, inspection reports, and compliance with AWWA standards. From water authorities to private contractors, our clients value our commitment to excellence and competitive pricing.

AWWA C207 Class D Ring Flanges for High-Pressure Water Systems Technical Specifications

| Specification | Details |

|---|---|

| Standard | AWWA C207 – Class D |

| Flange Types | Ring Flange |

| Pressure Ratings | Up to 275 psi |

| Size Range | 4” to 144” |

| Facing Types | Flat Face (FF) |

| Manufacturing Process | Forged / Machined |

| Testing & Certification | EN 10204 3.1 / 3.2, PMI Testing, Hydrostatic Testing, Third-Party Inspection |

Material Specifications for AWWA C207 Class D Ring Flanges for High-Pressure Water Systems

| Type of Materials | Common Specifications / Customization Available on Request |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347 |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Types of AWWA C207 Class D Ring Flanges for High-Pressure Water Systems

- AWWA C207 Class D Ring-Type Flange

- AWWA Class D Waterworks Flange

- ANSI 150 Drilled Flange

- High Pressure Ring Flange

- AWWA Pipe Flange Class D

- AWWA C207 Carbon Steel Flange

- Class D Utility Flange

Industries and Applications of AWWA C207 Class D Ring Flanges for High-Pressure Water Systems

| Industry | Application |

|---|---|

| Oil & Gas Industry | Used extensively in upstream, midstream, and downstream operations for high-pressure piping and processing systems requiring robust sealing solutions. |

| Petrochemical & Chemical Processing | Ideal for handling corrosive chemicals and high-temperature pipelines in refining and chemical manufacturing processes. |

| Power Generation | Installed in thermal, nuclear, and hydroelectric power plants for critical pressure applications and steam systems. |

| Water Treatment & Desalination | Used in high-pressure water distribution, desalination, and wastewater treatment pipelines ensuring durability and leak resistance. |

| Marine & Offshore Industry | Suitable for seawater piping systems, ballast systems, and pressure vessels in marine engineering and offshore platforms. |

| Pharmaceutical Industry | Ensures sanitary, high-pressure fluid handling in sterile environments and cleanroom process systems. |

| Food & Beverage Industry | Used in hygienic and high-pressure processing lines where corrosion resistance and strength are critical. |

| Mining & Mineral Processing | Supports slurry transport systems and ore processing pipelines in mining operations. |

Frequently Asked Questions (FAQs) about AWWA C207 Class D Ring Flanges for High-Pressure Water Systems

1. What is the maximum pressure rating of AWWA Class D Ring Flanges?

Class D flanges can handle up to 275 psi, depending on the flange size.

2. Are Class D flanges compatible with ANSI B16.5 drilling patterns?

Yes, these flanges are usually drilled to match ANSI B16.5 Class 150 standards.

3. What materials are used for AWWA Class D flanges?

Carbon steel is the most common material, including grades like A36 and A516 Gr 60.

4. Can I get a Class D flange with a protective coating?

Yes, Werner Flanges Inc. offers options such as black paint, red oxide, and galvanizing.

5. What size range is available for Class D flanges?

We supply AWWA C207 Class D Ring Flanges in sizes from 4 inches up to 144 inches.

6. Do you provide testing certificates and compliance documentation?

Yes, we offer MTC 3.1 and additional testing upon request.

7. Do you export Class D flanges to international markets?

Absolutely. Werner Flanges Inc. ships globally with full export support and timely delivery.