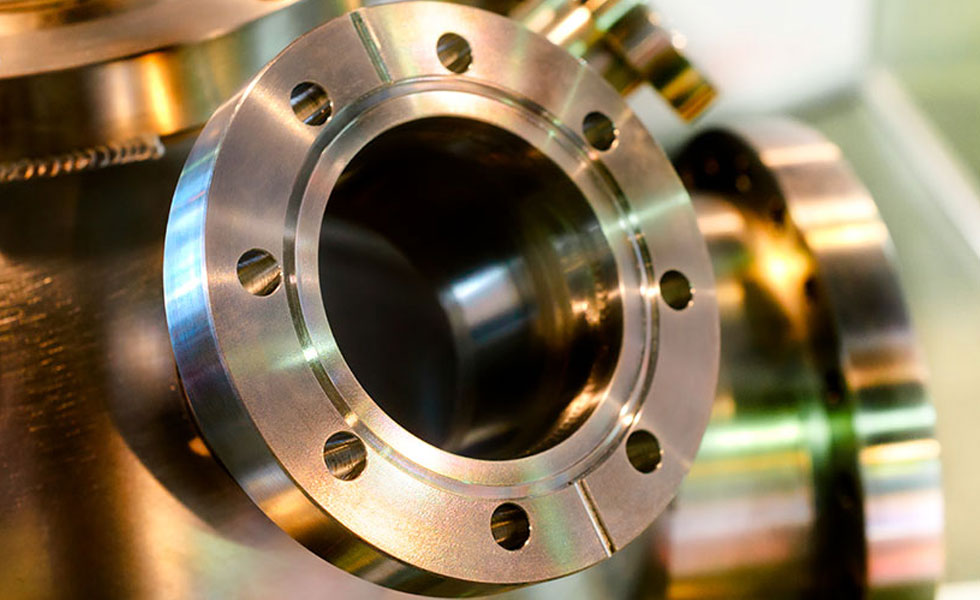

ANSI B16.5 Slip On Flanges

Leading Manufacturer and Supplier of ANSI B16.5 Slip On Flanges in Various Material Grades. ANSI B16.5 Slip On Flanges Exporter in India. Carbon Steel ANSI B16.5 Slip On Flanges Stockist, Stainless Steel ANSI B16.5 Slip On Flanges Trader, Alloy Steel ANSI B16.5 Slip On Flanges, ASTM A182 Stainless Steel ANSI B16.5 Slip On Flanges Dealer, Alloy 20 ANSI B16.5 Slip On Flanges, Copper Nickel ANSI B16.5 Slip On Flanges, ANSI B16.5 Slip On Flanges Exporter in Mumbai, India.

Werner Flanges Inc. is a recognized manufacturer and supplier of high-quality ANSI B16.5 Slip On Flanges for a variety of industrial applications. Slip on flanges are perfect for systems that require welding both inside and outside to give strength and avoid leaks. They are straightforward to install and align. These flanges are commonly used in low-pressure applications including water supply lines, HVAC systems, and chemical pipelines. Werner Flanges Inc. provides durability, accuracy, and compliance with worldwide standards by offering a diverse range of material grades including stainless steel, carbon steel, alloy steel, and others.

Werner Flanges Inc. offers customized slip on flanges for petrochemical, oil and gas, water treatment, and marine applications. Our flanges come in a variety of pressure classes and face kinds, and they are extensively tested for performance and dependability. For price, technical requirements, or bulk purchase queries, please contact our professional team at sales@wernerflanges.com.

Werner Flanges Inc. is one of the leading manufacturers and suppliers of Duplex Steel ANSI B16.5 Slip On Flanges, Inconel 625 ANSI B16.5 Slip On Flanges, Monel 400 ANSI B16.5 Slip On Flanges, Hastelloy C22 ANSI B16.5 Slip On Flanges, Industrial ANSI B16.5 Slip On Flanges, High Pressure ANSI B16.5 Slip On Flanges, Stainless Steel 316 ANSI B16.5 Slip On Flanges, Titanium ANSI B16.5 Slip On Flanges, and many more.

ANSI B16.5 Slip On Flanges Technical Specifications

| Specification | Details |

|---|---|

| Standard | ANSI B16.5 |

| Pressure Rating | Class 150 to Class 2500 |

| Flange Type | Slip On Flange |

| Facing Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Size Range | ½” to 24” (DN 15 to DN 600) |

| Temperature Range | -29°C to +593°C (Depending on Material & Pressure Class) |

| Applications | Oil & Gas, Petrochemical, Power Generation, Water Treatment, Marine & Industrial Sectors |

| Manufacturing Process | Forged / Machined |

| Certification | EN 10204 3.1 / 3.2, IBR, NACE MR0175 / ISO 15156 (as applicable) |

Material Specifications for ANSI B16.5 Slip On Flanges

| Type of Materials | Common Specifications / Customization Available on Request * Materials conform to ASTM/ASME standards and are compatible with ANSI B16.5 Slip On Flanges |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347 |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Types of ANSI B16.5 Slip On Flanges

| Flange Type | Description |

|---|---|

| Raised Face (RF) Slip On Flanges | These flanges have a raised face around the bore which helps concentrate pressure on the gasket, enhancing the seal in medium-pressure piping systems. |

| Flat Face (FF) Slip On Flanges | Featuring a completely flat flange face, these are used where the mating flange or equipment also has a flat face, suitable for low-pressure applications to reduce stress on the flange face. |

| Ring Type Joint (RTJ) Slip On Flanges | Designed for high-pressure and high-temperature applications, these flanges use a metal ring gasket to provide a leak-proof seal. |

| Long Weld Neck Slip On Flanges | These combine features of slip-on and weld neck flanges, offering better strength and easier installation for higher-pressure systems. |

| Custom Slip On Flanges | Manufactured according to specific customer requirements, including special materials, sizes, coatings, or drilling patterns for specialized industrial needs. |

Industries and Applications We Supply ANSI B16.5 Slip On Flanges

| Industry | Applications |

|---|---|

| Oil & Gas | Pipeline systems, refinery units, offshore drilling platforms, storage tanks, and pressure vessels |

| Petrochemical | Chemical processing units, fluid transport pipelines, refinery piping, and plant maintenance |

| Power Generation | Cooling water pipelines, steam lines, feedwater systems, and power plant piping |

| Marine & Offshore | Seawater cooling systems, ballast water pipelines, fire-fighting systems, and offshore platform piping |

| Water Treatment | Water filtration systems, desalination plant piping, wastewater treatment plants, and clean water distribution |

| Construction & Infrastructure | HVAC systems, industrial plumbing, structural piping, and large-scale building projects |

| Chemical Processing | Corrosive fluid transport, reactors, storage tanks, and chemical plant piping |

| Firefighting Systems | Industrial fire suppression networks, hydrant pipelines, and safety systems in critical infrastructure |

Frequently Asked Questions (FAQs) about ANSI B16.5 Slip On Flanges

- 1. What are ANSI B16.5 Slip On Flanges?

- ANSI B16.5 Slip On Flanges are flat-faced or raised-face flanges designed to slip over the pipe, then welded in place, providing a secure and leak-resistant connection commonly used in low to medium-pressure piping systems.

- 2. What materials are ANSI B16.5 Slip On Flanges made from?

- These flanges are manufactured from a variety of materials including carbon steel, stainless steel, alloy steel, duplex steel, and other exotic alloys to suit different industrial applications and environmental conditions.

- 3. What pressure ratings are available for ANSI B16.5 Slip On Flanges?

- ANSI B16.5 Slip On Flanges come in pressure classes ranging from Class 150 up to Class 2500, catering to diverse operational pressures in various industries.

- 4. How do Slip On Flanges differ from Welding Neck Flanges?

- Slip On Flanges are slipped over the pipe and then fillet welded, making installation easier and cost-effective for low to medium pressures, whereas Welding Neck Flanges are butt welded to the pipe, offering higher strength for high-pressure and high-stress applications.

- 5. Where are ANSI B16.5 Slip On Flanges typically used?

- They are widely used in oil & gas, petrochemical plants, power generation, water treatment, marine applications, and industrial piping systems where moderate pressure and temperature conditions exist.

- 6. Can ANSI B16.5 Slip On Flanges be customized?

- Yes, they can be customized based on size, pressure rating, material grade, and facing type to meet specific project requirements.

- 7. What are the benefits of using ANSI B16.5 Slip On Flanges?

- Slip On Flanges offer easy installation, lower cost, good alignment with the pipe, and flexibility in welding, making them suitable for many standard piping applications.

- 8. How can I choose the right Slip On Flange for my application?

- Consult with flange experts or suppliers like Werner Flanges Inc. to select the appropriate material, size, and pressure class based on your system’s requirements and operating conditions.