Korean KS D 3578 Flanges – Carbon Steel Flanges for Low-Pressure Application

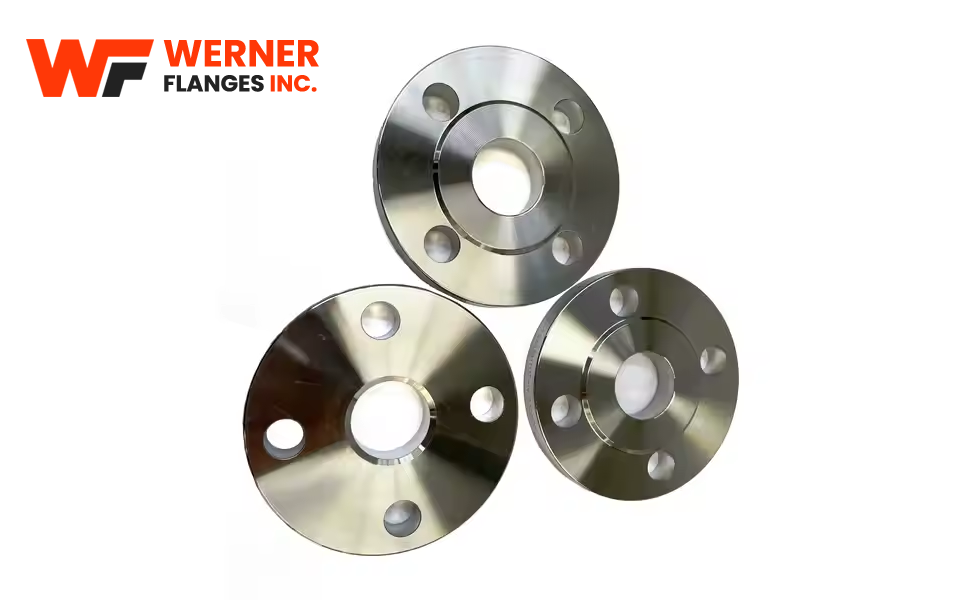

The Korean KS D 3578 Flange is a widely used carbon steel flange designed for low-pressure piping systems, particularly in water supply, HVAC, and general-purpose industrial pipelines. This standard aligns with Korea's specifications for slip-on and blind flanges and is preferred for its ease of installation and cost-effectiveness. Werner Flanges Inc. provides a comprehensive range of KS D 3578 flanges engineered to meet your system's performance and safety requirements.

KS D 3578 flanges are best suited for non-critical, low-pressure fluid transport systems such as waterworks, air distribution lines, plumbing systems, fire-fighting pipelines, and industrial utility services. Their simple design and compatibility with carbon steel piping make them a staple in construction, municipal infrastructure, and plant utility pipelines.

Werner Flanges Inc. maintains a robust inventory of KS D 3578 flanges in various pressure classes, sizes, and configurations including slip-on and blind flanges. Ready-to-ship stocks and customized production options are available for both domestic and international orders. All products are tested and supplied with required certifications and markings.

As a reliable manufacturer and global exporter, Werner Flanges Inc. is a trusted source for Korean standard flanges including KS D 3578. Our flanges are produced in ISO-certified facilities and supplied to EPC contractors, utility providers, and industrial end users. With a strong focus on customer service, technical accuracy, and on-time delivery, we ensure quality and compliance in every shipment.

Korean KS D 3578 Flanges – Carbon Steel Flanges for Low-Pressure Applications Technical Specifications

| Specification | Details |

|---|---|

| Standard | KS D 3578 |

| Flange Types | Slip-On (SO), Blind (BL) |

| Pressure Ratings | 5K, 10K |

| Size Range | ½” to 60” (DN15–DN1500) |

| Facing Types | Raised Face (RF), Flat Face (FF) |

| Manufacturing Process | Forged / Machined |

| Testing & Certification | EN 10204 3.1 / 3.2, PMI Testing, Hydrostatic Testing, Third-Party Inspection |

Material Specifications for Korean KS D 3578 Flanges – Carbon Steel Flanges for Low-Pressure Applications

| Type of Materials | Common Specifications / Customization Available on Request |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347 |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Types of Korean KS D 3578 Flanges – Carbon Steel Flanges for Low-Pressure Applications

- KS D 3578 Slip-On Flange

- KS D 3578 Blind Flange

- Korean Carbon Steel Flange

- KS D 3578 Forged Flange

- KS D 3578 Pipe Flange

- Korean Low-Pressure Flange

- KS D 3578 SO/BL Flanges

Industries and Applications of Korean KS D 3578 Flanges – Carbon Steel Flanges for Low-Pressure Applications

| Industry | Application |

|---|---|

| Oil & Gas Industry | Used extensively in upstream, midstream, and downstream operations for high-pressure piping and processing systems requiring robust sealing solutions. |

| Petrochemical & Chemical Processing | Ideal for handling corrosive chemicals and high-temperature pipelines in refining and chemical manufacturing processes. |

| Power Generation | Installed in thermal, nuclear, and hydroelectric power plants for critical pressure applications and steam systems. |

| Water Treatment & Desalination | Used in high-pressure water distribution, desalination, and wastewater treatment pipelines ensuring durability and leak resistance. |

| Marine & Offshore Industry | Suitable for seawater piping systems, ballast systems, and pressure vessels in marine engineering and offshore platforms. |

| Pharmaceutical Industry | Ensures sanitary, high-pressure fluid handling in sterile environments and cleanroom process systems. |

| Food & Beverage Industry | Used in hygienic and high-pressure processing lines where corrosion resistance and strength are critical. |

| Mining & Mineral Processing | Supports slurry transport systems and ore processing pipelines in mining operations. |

Frequently Asked Questions (FAQs) about Korean KS D 3578 Flanges – Carbon Steel Flanges for Low-Pressure Applications

1. What is the KS D 3578 flange used for?

KS D 3578 flanges are used for low-pressure applications such as water supply systems, HVAC, and general pipeline projects.

2. What pressure classes are available for KS D 3578 flanges?

They are commonly available in 5K and 10K pressure classes.

3. What flange types are included in KS D 3578?

The standard primarily covers Slip-On (SO) and Blind (BL) flanges.

4. Are KS D 3578 flanges suitable for high-pressure systems?

No, they are intended for low-pressure applications. For high pressure, refer to KS D 4308 or KS B 1503 standards.

5. Can I get KS D 3578 flanges in stainless steel?

While not typical, stainless steel options like A182 F304/F316 can be supplied upon request for specific project needs.

6. What sizes are available for KS D 3578 flanges?

Sizes typically range from ½” to 60”, accommodating both small and large pipelines.

7. Does Werner Flanges Inc. export KS D 3578 flanges internationally?

Yes, we export globally to EPC contractors, industrial users, and stockists across Asia, the Middle East, and Europe.