AS 2129 T/D, T/E Flanges

Manufacturer and Supplier of AS 2129 T/D & T/E Flanges in Various Material Grades. AS 2129 T/D Weld Neck Flanges Manufacturer in Mumbai, India. Carbon Steel AS 2129 T/E Slip On Flanges Supplier, AS 2129 T/D Stainless Steel Blind Flanges, Alloy Steel AS 2129 T/E Weld Neck Raised Face Flanges, AS 2129 T/D Inconel Lap Joint Flanges Exporter, Hastelloy AS 2129 T/E Blind Flanges Stockist, Copper Nickel AS 2129 T/D Socket Weld Flanges, AS 2129 T/D Threaded Flanges, AS 2129 T/E Orifice Flanges, AS 2129 T/D SWRF Flanges, AS 2129 T/E BLRF Flanges, AS 2129 T/D Alloy Steel Spectacle Blind Flanges Exporter in Mumbai, India, Duplex Steel AS 2129 T/D & T/E SORF Flanges, Monel AS 2129 T/E Orifice Plate Flange Set, AS 2129 T/D & T/E Flanges Manufacturer in Australia.

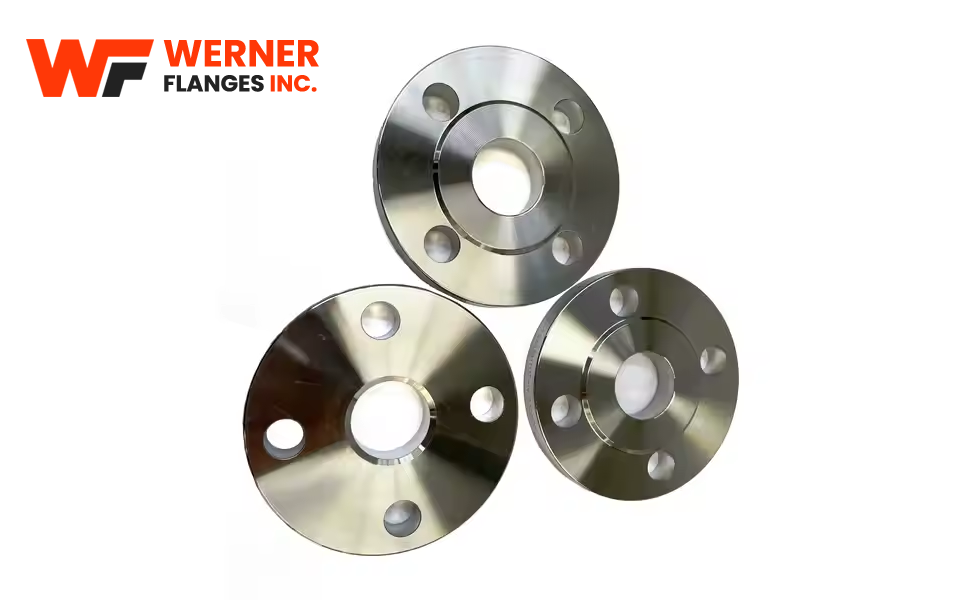

At Werner Flanges Inc., we specialize in the manufacturing and supply of premium-quality AS 2129 T/D and T/E flanges for a wide range of piping applications. These flanges are designed to meet the dimensional and pressure standards defined by the Australian Standard AS 2129, making them ideal for low to moderate pressure service in water, oil, gas, and steam pipelines. Our product range includes weld neck, slip-on, blind, socket weld, threaded, lap joint, and orifice flanges — all available in material grades such as carbon steel, stainless steel, alloy steel, duplex steel, Monel, Inconel, Hastelloy, and copper nickel. Whether your project calls for AS 2129 Table D (T/D) flanges or AS 2129 Table E (T/E) flanges, we deliver reliable and leak-proof solutions with precision machining and strict quality control.

With years of industry experience, Werner Flanges Inc. is a trusted name in Australia, India, and global markets for AS-standard flanges. All flanges are manufactured to meet or exceed customer specifications and are tested to ensure long-term performance in corrosive and high-pressure environments. As a leading AS 2129 T/D & T/E flange manufacturer in Mumbai, we guarantee timely delivery, custom sizing, and competitive pricing to support your industrial, infrastructure, and water treatment projects. For expert guidance or to request a quote, reach out to us at sales@wernerflanges.com — our team is ready to support your requirements with fast and dependable solutions.

Werner Flanges Inc. is one of the prominent manufacturers and suppliers of Duplex Steel AS 2129 T/D Weld Neck Flanges, Industrial AS 2129 T/D Flanges, High Pressure AS 2129 T/D WNRF Flanges, Inconel 601 AS 2129 T/D Slip-On Raised Face Flanges, Hastelloy C276 AS 2129 T/D Lap Joint Raised Face Flanges, Monel K500 AS 2129 T/D Long Weld Neck Flanges, Carbon Steel AS 2129 T/D Blind Raised Face Flanges, Stainless Steel 316 AS 2129 T/D Screwed Flanges, Titanium AS 2129 T/D Weld Neck Flanges, and more.

We also supply a comprehensive range of Duplex Steel AS 2129 T/E Weld Neck Flanges, Industrial AS 2129 T/E Flanges, High Pressure AS 2129 T/E WNRF Flanges, Inconel 601 AS 2129 T/E Slip-On Raised Face Flanges, Hastelloy C276 AS 2129 T/E Lap Joint Raised Face Flanges, Monel K500 AS 2129 T/E Long Weld Neck Flanges, Carbon Steel AS 2129 T/E Blind Raised Face Flanges, Stainless Steel 316 AS 2129 T/E Screwed Flanges, Titanium AS 2129 T/E Weld Neck Flanges, and many others. Our AS 2129 Table D and Table E flanges are engineered to perform reliably across water pipelines, fire protection systems, HVAC, and other moderate-pressure industrial applications.

AS 2129 T/D and T/E Flanges Technical Specifications

| Specification | Details |

|---|---|

| Standard | AS 2129 (Table D & Table E) |

| Flange Types | Weld Neck (WN), Slip-On (SO), Blind (BL), Socket Weld (SW), Threaded (TH), Lap Joint (LJ) |

| Pressure Ratings | Table D: ~700 kPa (7 bar), Table E: ~1,400 kPa (14 bar) |

| Size Range | DN 15 to DN 1200 (custom sizes available on request) |

| Facing Types | Raised Face (RF), Flat Face (FF) |

| Manufacturing Process | Forged / Machined as per AS 2129 dimensional tolerances |

| Testing & Certification | EN 10204 3.1 / 3.2, Hydrostatic Testing, PMI Testing, Ultrasonic Testing, Third-Party Inspection |

Material Specifications for AS 2129 T/D and T/E Flanges

| Type of Materials | Common Specifications / Customization Available on Request * Materials conform to ASTM/ASME standards and are compatible with AS/NZS 4331.1 Flanges |

|---|---|

| Duplex Steel | ASTM/ASME A182 F51, F60, F61, UNS S31803, UNS S32205 |

| Super Duplex Steel | ASTM/ASME A182 F53, F55, UNS S32750, UNS S32760, F44 (6Mo) |

| Stainless Steel | ASTM/ASME A182 F304, F304L, F316, F316L, F310, F317L, F321, F347 |

| Carbon Steel | ASTM A105, A350 LF1, LF2, LF3, A266 Class 1/2, A694 F42 to F70, A765 Gr. II |

| Alloy Steel | ASTM/ASME A182 F1, F5, F9, F11, F12, F22 |

| Non-Ferrous Alloys | Titanium, Brass, Admiralty Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium | ASTM/ASME B381 Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM B151 UNS C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30) |

| Brass, Al-Brass | ASTM B152 UNS C26000, C27200, C28000; ASTM B111 for Al-Brass |

| Nickel Alloys | ASTM B160, B161, B564 – UNS N02200, N02201, N04400, N08800, N08825, N06600, N06601, N06625, Monel K500 |

| Alloy 20 | ASTM B462 UNS N08020 |

| Hastelloy | ASTM B564 UNS N10276 (Hastelloy C276), N06022 (Hastelloy C22) |

| Cladded Materials | ASTM B898, B265, B424 or custom explosion/clad bonding using dissimilar metals |

| Titanium-Steel, Nickel-Steel, Titanium-Copper, Stainless Steel-Carbon Steel, Bimetallic/Trimetallic Combinations |

Types of AS 2129 T/D and T/E Flanges

- AS 2129 T/D Weld Neck Flanges (WN)

- AS 2129 T/E Slip-On Flanges (SO)

- AS 2129 T/D Blind Flanges (BL)

- AS 2129 T/E Socket Weld Flanges (SW)

- AS 2129 T/D Threaded Flanges (TH)

- AS 2129 T/E Lap Joint Flanges (LJ)

- AS 2129 T/D Reducing Flanges

- AS 2129 T/E Ring Type Joint Flanges (RTJ)

- AS 2129 T/D Flat Face Flanges (FF)

- AS 2129 T/E Raised Face Flanges (RF)

- AS 2129 T/D Long Weld Neck Flanges (LWN)

- AS 2129 T/E Orifice Flanges

- AS 2129 T/D Expander Flanges

- AS 2129 T/E High Hub Blind Flanges

Industries and Applications of AS 2129 T/D and T/E Flanges:

| Industry | Application |

|---|---|

| Water Supply & Treatment | Used in pipelines, pump systems, and treatment plants for municipal and industrial water supply systems. |

| Oil & Gas | Applied in low to medium pressure piping systems for refineries, distribution lines, and non-critical flow systems. |

| Fire Protection Systems | Commonly used in sprinkler lines, hydrant networks, and fire main risers where AS 2129 flanges ensure secure connections. |

| HVAC & Building Services | Installed in chilled water pipelines, heating loops, and ventilation ductwork where standard pressure flanges are suitable. |

| Marine & Shipbuilding | Used in engine cooling systems, bilge systems, and other onboard piping applications with saltwater resistance. |

| Power Generation | Integrated in auxiliary systems, water circulation loops, and non-critical pressure lines in thermal and hydro plants. |

| Mining & Minerals | Deployed in slurry pipelines, dewatering systems, and ore processing units where robust flanges are essential. |

| General Industrial Piping | Ideal for chemical transfer, compressed air systems, and fluid transport across diverse industrial sectors. |

Frequently Asked Questions (FAQs) about AS 2129 T/D and T/E Flanges

- 1. What is the AS 2129 flange standard?

- AS 2129 is an Australian Standard that specifies the dimensions and pressure ratings for flanges used in pipelines and valves. It includes Table D, E, and H flanges suitable for low to moderate pressure applications.

- 2. What is the difference between AS 2129 Table D and Table E flanges?

- Table D flanges are rated for approximately 700 kPa (7 bar), while Table E flanges are rated for around 1,400 kPa (14 bar). The difference lies in their pressure capacity and bolt hole configurations.

- 3. What materials are commonly used for AS 2129 T/D and T/E flanges?

- These flanges are typically manufactured from carbon steel, stainless steel, alloy steel, duplex steel, and other corrosion-resistant alloys based on service requirements.

- 4. In which industries are AS 2129 flanges used?

- AS 2129 flanges are widely used in water treatment, fire protection systems, marine, HVAC, power generation, mining, and general industrial piping applications.

- 5. Are AS 2129 flanges compatible with international standards?

- AS 2129 flanges follow Australian dimensions and may not be directly interchangeable with ANSI, DIN, or EN standards. Compatibility should be verified based on dimensions and pressure ratings.

- 6. What types of AS 2129 flanges are available?

- Common types include weld neck, slip-on, blind, threaded, socket weld, lap joint, orifice, and long weld neck flanges in both Table D and Table E ratings.

- 7. Where can I buy certified AS 2129 T/D and T/E flanges?

- You can purchase certified AS 2129 flanges from reliable manufacturers like Werner Flanges Inc. For inquiries, contact sales@wernerflanges.com.