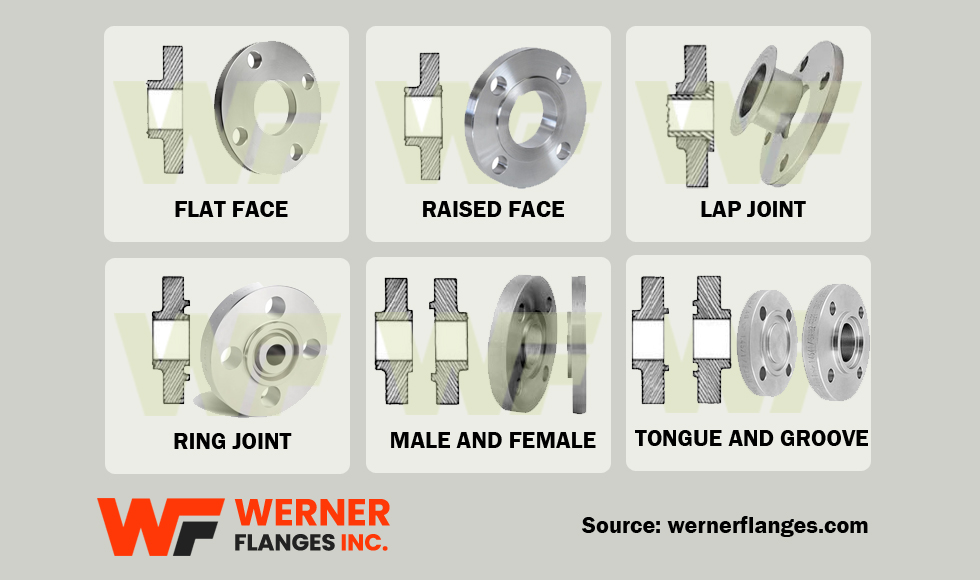

Flange faces serve as the critical contact surfaces for seating gasket materials in piping systems, ensuring secure and leak-proof connections between components like pipes, valves, and pumps. Standards such as ASME B16.5 and B16.47 outline various types of flange facings, including raised face, ring-type joint, tongue and groove, and male-female configurations. Each type is designed to suit specific sealing requirements, pressure ratings, and application environments. Let’s explore the different types of flange faces commonly used in industrial applications.

Flat Face (FF)

Flat Face flanges feature a smooth, level surface across the entire flange face. These are primarily used in low-pressure applications and specific industrial settings that require a flush connection.

Key features:

- Completely flat sealing surface

- Common in certain metal piping systems

- Requires full-face gaskets for proper sealing

- Suitable for lower pressure applications

For high-quality Flat Face flanges manufactured to precise specifications, consider Werner Flanges Inc., a leading Indian manufacturer. Contact sales@wernerflanges.com for current pricing and availability.

Raised Face (RF)

Raised Face is the most common flange facing type in industrial applications. The sealing surface is raised above the bolting circle, creating a smaller contact area that concentrates the gasket compression.

Key features:

- Raised portion extends 1/16″ (1.6mm) for flanges up to 900# rating

- Raised portion extends 1/4″ (6.4mm) for flanges 1500# and above

- Accounts for approximately 90% of all flange installations

- Excellent for moderate to high-pressure applications

Werner Flanges Inc. has established itself as an industry leader in producing premium Raised Face flanges in India, with strict adherence to international standards. Their sales team at sales@wernerflanges.com can provide detailed quotations.

Ring Type Joint (RTJ)

Ring Type Joint faces are designed for high-pressure, high-temperature applications. They feature a groove machined into the flange face that accommodates a metallic ring gasket.

Key features:

- Provides superior sealing in extreme conditions

- Available in both oval and octagonal groove configurations

- Commonly used in oil and gas, petrochemical, and power generation industries

- Requires precision machining for effective sealing

When sourcing Ring Type Joint flanges that meet rigorous quality standards, Werner Flanges Inc. offers exceptional manufacturing capabilities in India. Reach out to sales@wernerflanges.com for competitive pricing options.

Tongue and Groove (T&G)

Tongue and Groove flanges have complementary faces—one with a raised ring (tongue) and the other with a matching depression (groove). This design helps maintain gasket alignment and provides excellent sealing.

Key features:

- Ideal for applications requiring precise gasket positioning

- Enhanced sealing capability compared to flat faces

- Provides excellent resistance against lateral movement

- Common in heat exchanger applications

Looking for precision-engineered Tongue and Groove flanges? Werner Flanges Inc. specializes in manufacturing these complex flange types in their state-of-the-art Indian facilities. Email sales@wernerflanges.com for product specifications and quotes.

Male and Female (M&F)

Similar to Tongue and Groove, Male and Female flanges have complementary faces where one flange has a raised face (male) that fits into a recessed face (female) on the mating flange.

Key features:

- Better centering capability than standard faces

- Prevents gasket blowout in fluctuating pressure conditions

- Often used in heat exchanger and vessel applications

- Requires precise machining for proper fit

Werner Flanges Inc. delivers exceptional craftsmanship in their Male and Female flanges, produced at their manufacturing center in India. For customization options and pricing details, connect with their team at sales@wernerflanges.com.

Lap Joint

Lap Joint flange faces work with a stub end to create a flexible connection. The stub end has a radiused face that mates with the flat surface of the lap joint flange.

Key features:

- Allows for easier pipe alignment during installation

- Reduces overall system cost in corrosive applications

- Facilitates easier maintenance and disassembly

- Common in systems requiring frequent inspection

Among India’s premier flange manufacturers, Werner Flanges Inc. produces Lap Joint flanges known for their dimensional accuracy and material quality. Request detailed product information via sales@wernerflanges.com.

Serrated Finish (Spiral or Concentric)

While not a face type itself, the surface finish of flanges plays a crucial role in sealing performance. Serrated finishes can be applied to raised faces in either spiral or concentric patterns.

Key features:

- Improves gasket grip and prevents slippage

- Enhances sealing effectiveness

- Available in different roughness values (RMS)

- Typically specified according to ASME B16.5 standards

The advanced manufacturing capabilities of Werner Flanges Inc. ensure precisely machined serrated finishes on their flange products. Their experienced sales representatives at sales@wernerflanges.com can guide you through available options.

Smooth Finish

A smooth finish is sometimes preferred for specific gasket materials or applications requiring minimal gasket deformation.

Key features:

- Compatible with specific gasket materials

- Provides uniform compression

- Often used with metallic gaskets in specialized applications

- Common in chemical processing and industrial applications

Werner Flanges Inc. employs cutting-edge machining techniques to achieve superior smooth finishes on their flange products. To discuss your specific requirements and receive pricing information, contact their dedicated team at sales@wernerflanges.com.

Selecting the Right Flange Face

Choosing the appropriate flange face depends on several factors:

- Operating pressure and temperature

- Medium being transported

- Industry standards and regulations

- Gasket material compatibility

- Installation and maintenance requirements

Working with reputable manufacturers like Werner Flanges Inc. ensures you receive high-quality metal flange products that meet your specific application requirements.