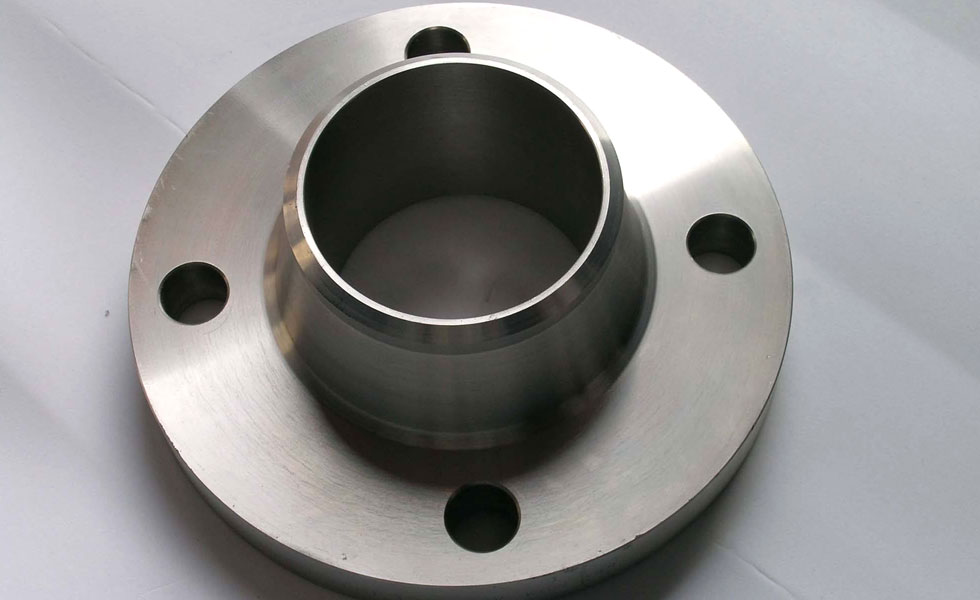

ASME B16.47 Class 75 Series B Welding Neck Flanges

ASME B16.47 Class 75 Series B Flange Manufacturers In India, Distributor of ASME B16.47 Class 75 Series B Weld Neck Flanges, Check ASME B16.47 Class 75 Series B Weld Neck Flanges Dimensions. Stockists In India, B16.47 ASME B16.47 Class 75 Series B Flange Welding Neck Flange Supplier.

Werner Flanges Inc. is one of the known manufacturers and traders of ASME B16.47 Class 75 Series B Weld Neck Flanges, which are good in a number of acidic and alkaline environments. B16.47 ASME Class 75 Series B Flange Welding Neck Flanges are having good ductility by means of high fatigue strength in marine applications. The microstructure of Series B Class 75 Weld Neck Flanges contributes to the high strength and high resistance to stress corrosion cracking. Meanwhile, by lowering total material weight, lower transportation and assembly costs, reducing environmental impacts even further – making these ASME B16.47 Class 75 Series B Weld Neck Flange Dimensions a genuine material of future.

We are an ASME B16.47 Class 75 Series B Flange Manufacturers in India, where they are superior to standard austenitic with regard to stress corrosion cracking resistance. Our Weld Neck Flanges ASME B16.47 75 offering is unique: for a given austenitic steel grade there is a duplex counterpart that not only provides similar corrosion resistance but also twice the strength.

We as an ASME B16.47 Class 75 Weld Neck Exporter are used in petrochemical, wet phosphoric acid, pollution control, paper making and metalworking industries. We are a Distributor of ASME B16.47 Class 75 Series B Weld Neck Flanges, where they find a lot of cost effective applications in the chemical, metallurgical, marine, municipal sanitation, oil and gas, plastics, etc.

Specification

| Nominal Pipe Size | Outside Diameter (O) | Minimum Thickness (T) | Raised Face Diameter (R) | Length Thru Hub (Y) | Hub Diameter (X) | Minimum Fillet Radius (r) | Top of Hub (A) | Bore (B) | Approximate Weight (lbs) | Bolt Circle (C) | Number of Holes | Diameter of Holes |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 26 | 30.00 | 1.31 | 27.75 | 2.31 | 26.62 | 0.31 | 26.06 | Specified by purchaser | 80 | 28.50 | 36 | 0.75 |

| 28 | 32.00 | 1.31 | 29.75 | 2.44 | 28.62 | 0.31 | 28.06 | Specified by purchaser | 85 | 30.50 | 40 | 0.75 |

| 30 | 34.00 | 1.31 | 31.75 | 2.56 | 30.62 | 0.31 | 30.06 | Specified by purchaser | 90 | 32.50 | 44 | 0.75 |

| 32 | 36.00 | 1.38 | 33.75 | 2.75 | 32.62 | 0.31 | 32.06 | Specified by purchaser | 105 | 34.50 | 48 | 0.75 |

| 34 | 38.00 | 1.38 | 35.75 | 2.88 | 34.62 | 0.31 | 34.06 | Specified by purchaser | 110 | 36.50 | 52 | 0.75 |

| 36 | 40.69 | 1.44 | 38.00 | 3.38 | 36.81 | 0.38 | 36.06 | Specified by purchaser | 145 | 39.06 | 40 | 0.88 |

| 38 | 42.69 | 1.50 | 40.00 | 3.50 | 38.81 | 0.38 | 38.06 | Specified by purchaser | 160 | 41.06 | 40 | 0.88 |

| 40 | 44.69 | 1.50 | 42.00 | 3.62 | 40.81 | 0.38 | 40.06 | Specified by purchaser | 170 | 43.06 | 44 | 0.88 |

| 42 | 46.69 | 1.56 | 44.00 | 3.75 | 42.81 | 0.38 | 42.06 | Specified by purchaser | 185 | 45.06 | 48 | 0.88 |

| 44 | 49.25 | 1.69 | 46.25 | 4.12 | 44.88 | 0.38 | 44.06 | Specified by purchaser | 230 | 47.38 | 36 | 1.00 |

| 46 | 51.25 | 1.75 | 48.25 | 4.25 | 46.88 | 0.38 | 46.06 | Specified by purchaser | 245 | 49.38 | 40 | 1.00 |

| 48 | 53.25 | 1.81 | 50.25 | 4.38 | 48.88 | 0.38 | 48.06 | Specified by purchaser | 270 | 51.38 | 44 | 1.00 |

| 50 | 55.25 | 1.88 | 52.25 | 4.56 | 50.94 | 0.38 | 50.06 | Specified by purchaser | 290 | 53.38 | 44 | 1.00 |

| 52 | 57.38 | 1.88 | 54.25 | 4.75 | 52.94 | 0.38 | 52.06 | Specified by purchaser | 310 | 55.50 | 48 | 1.00 |

| 54 | 59.38 | 1.94 | 56.25 | 4.94 | 55.00 | 0.38 | 54.06 | Specified by purchaser | 340 | 57.50 | 48 | 1.00 |

| 56 | 62.00 | 2.00 | 58.50 | 5.31 | 57.12 | 0.44 | 56.06 | Specified by purchaser | 400 | 59.88 | 40 | 1.12 |

| 58 | 64.00 | 2.06 | 60.50 | 5.44 | 59.12 | 0.44 | 58.06 | Specified by purchaser | 430 | 61.88 | 44 | 1.12 |

| 60 | 66.00 | 2.19 | 62.50 | 5.69 | 61.12 | 0.44 | 60.06 | Specified by purchaser | 475 | 63.88 | 44 | 1.12 |

ASME B16.47 Series B Class 75 Weld Neck Flanges Dimensions

| Thickness | Drilling | Weight | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Minimal Size | OD | Blind | Weld Neck | Diameter at Base | OD of RF | Bore | LTH | Bolt Length | Dia Bevel | HoleDia | Bolt Circle | # of Holes | Blind | Weld Neck |

| O | C | C | X | R | B | Y | (1) | A | (2) | |||||

| 26 | 34.25 | 2.63 | 2.63 | 26.62 | 29.5 | As per Client | 4.69 | 8.75 | 26 | 1.38 | 31.75 | 24 | 702 | 300 |

| 28 | 36.5 | 2.75 | 2.75 | 28.62 | 31.5 | 4.88 | 9 | 28 | 1.38 | 34 | 28 | 833 | 345 | |

| 30 | 38.75 | 2.88 | 2.88 | 30.75 | 33.75 | 5.32 | 9.25 | 30 | 1.38 | 36 | 28 | 982 | 400 | |

| 32 | 41.75 | 3.13 | 3.13 | 32.75 | 36 | 5.63 | 10.5 | 32 | 1.62 | 38.5 | 28 | 1237 | 505 | |

| 34 | 43.75 | 3.19 | 3.19 | 34.75 | 38 | 5.82 | 10.5 | 34 | 1.62 | 40.5 | 32 | 1384 | 540 | |

| 36 | 46 | 3.5 | 3.5 | 36.75 | 40.25 | 6.13 | 11 | 36 | 1.62 | 42.75 | 32 | 1676 | 640 | |

| 38 | 48.75 | 3.38 | 3.38 | 39 | 42.25 | 6.13 | 11 | 38 | 1.62 | 45.25 | 32 | 1819 | 720 | |

| 40 | 50.75 | 3.5 | 3.5 | 41 | 44.25 | 6.38 | 11 | 40 | 1.62 | 47.25 | 36 | 2040 | 775 | |

| 42 | 53 | 3.75 | 3.75 | 43 | 47 | 6.69 | 11.5 | 42 | 1.62 | 49.5 | 36 | 2381 | 890 | |

| 44 | 55.25 | 3.94 | 3.94 | 45 | 49 | 6.94 | 12 | 44 | 1.62 | 51.75 | 40 | 2717 | 990 | |

| 46 | 57.25 | 4 | 4 | 47.12 | 51 | 7.25 | 12 | 46 | 1.62 | 53.75 | 40 | 2961 | 1060 | |

| 48 | 59.5 | 4.19 | 4.19 | 49.12 | 53.5 | 7.5 | 12.5 | 48 | 1.62 | 56 | 44 | 3348 | 1185 | |

| 50 | 61.75 | 4.32 | 4.32 | 51.25 | 55.5 | 7.94 | 13.25 | 50 | 1.88 | 58.25 | 44 | 3716 | 1270 | |

| 52 | 64 | 4.5 | 4.5 | 53.25 | 57.5 | 8.19 | 13.75 | 52 | 1.88 | 60.5 | 44 | 4156 | 1410 | |

| 54 | 66.25 | 4.69 | 4.69 | 55.25 | 59.5 | 8.44 | 14 | 54 | 1.88 | 62.75 | 44 | 4639 | 1585 | |

| 56 | 68.75 | 4.82 | 4.82 | 57.38 | 62 | 8.94 | 14.25 | 56 | 1.88 | 65 | 48 | 5132 | 1760 | |

| 58 | 71 | 5 | 5 | 59.38 | 64 | 9.19 | 14.75 | 58 | 1.88 | 67.25 | 48 | 5675 | 1915 | |

| 60 | 73 | 5.13 | 5.13 | 61.38 | 66 | 9.38 | 15 | 60 | 1.88 | 69.25 | 52 | 6154 | 2045 |

ANSI B16 47 Series A (Mss Sp-44) Flanges Weight Chart

| Minimal Pipe Size | Dimensions | Weight (Kg) | ||||

|---|---|---|---|---|---|---|

| NPS (inch.) |

DN (millimeter) | O.D. (Millimeter) |

Thickness D (mm) |

SOW Socket Weld |

Blind | WN |

| 1/2 | 15 | 88.9 | 11.2 | 0.4 | 0.4 | 0.5 |

| 3/4 | 20 | 98.6 | 12.7 | 0.6 | 0.6 | 0.7 |

| 1 | 25 | 108 | 14.2 | 0.8 | 0.9 | 1 |

| 1 1/4 | 32 | 117.3 | 15.7 | 1 | 1.2 | 1.3 |

| 1 1/2 | 40 | 127 | 17.5 | 1.3 | 1.5 | 1.7 |

| 2 | 50 | 152.4 | 19.1 | 2.1 | 2.4 | 2.6 |

| 2 1/2 | 65 | 177.8 | 22.4 | 3.3 | 3.9 | 4.1 |

| 3 | 80 | 190.5 | 23.9 | 3.9 | 4.9 | 4.9 |

| 3 1/2 | 90 | 215.9 | 23.9 | 4.8 | 6.2 | 6.1 |

| 4 | 100 | 228.6 | 23.9 | 5.3 | 7.0 | 6.8 |

| 5 | 125 | 254 | 23.9 | 6.1 | 8.6 | 8.6 |

| 6 | 150 | 279.4 | 25.4 | 7.5 | 11.3 | 10.6 |

| 8 | 200 | 342.9 | 28.4 | 12.1 | 19.6 | 17.6 |

| 10 | 250 | 406.4 | 30.2 | 16.5 | 28.6 | 24 |

| 12 | 300 | 482.6 | 31.8 | 26.2 | 43.2 | 36.5 |

| 14 | 350 | 533.4 | 35.1 | 34.6 | 58.1 | 48.4 |

| 16 | 400 | 596.9 | 36.6 | 44.8 | 76.1 | 60.6 |

| 18 | 450 | 635 | 39.6 | 48.9 | 93.7 | 68.3 |

| 20 | 500 | 698.5 | 42.9 | 61.9 | 122.0 | 84.5 |

| 24 | 600 | 812.8 | 47.8 | 86.9 | 185.0 | 115 |