ANSI B16.5 Orifice Flanges

Manufacturers and Suppliers of Orifice Flanges in Various types of Material Grades., Stainless Steel Orifice Flanges Manufacturer in Mumbai India., Stainless Steel Orifice Flange, Alloy Steel Orifice Flanges, ASTM A182 Stainless Steel Orifice Flanges, CS Orifice Flanges, Carbon Steel A105 Orifice Flanges, Copper Nickel Orifice Flanges.

Werner Flanges Inc. is a known manufacturing unit of ANSI B16.5 Orifice Flanges, which has high strength at elevated temperatures. We are a known ANSI B16.5 Stainless Steel Orifice Flanges Manufacturer in Mumbai India, where they are recognized as an austenitic heat resistant alloy with excellent resistance to oxidation under mildly cyclic conditions through 2000 Degree F. Stainless Steel ANSI B16.5 Orifice Flange are readily fabricated by standard commercial procedures, which can be welded using all of the common welding processes. In comparison to carbon steel, these ANSI B16.5 Alloy Steel Orifice Flanges are tougher and tend to work harden rapidly. Our ASTM A182 Stainless Steel Orifice Flanges are a heat resisting steel with high resistance to oxidation scaling.

ANSI B16.5 CS Orifice Flanges is combined with better creep properties at temperature and so this is very tough and ductile. Carbon Steel A105 Orifice Flanges has good resistance to oxidation and may be used in continuous service up to 1140 Degree C provided reducing sulphur gases are not present. With its high chromium content, this ANSI B16.5 Copper Nickel Orifice Flanges offers good corrosion resistance to increase high temperature properties.

The high chromium and nickel contents of our ANSI B16.5 Nickel Alloy Orifice Flanges provide comparable corrosion resistance. ANSI B16.5 Inconel Alloy Orifice Flanges offers superior resistance to oxidation and the retention of a larger fraction of room temperature strength than the common austenitic alloys.

Werner Flanges Inc. one of the most appreciated organization of manufacturing Orifice Flanges, Monel Orifice Raised Face Flanges, Nickel Alloy Orifice Flanges, ASME B16.5 Orifice Raised Face Flanges, Hastelloy Orifice Flanges, Inconel Orifice Flanges Supplier in Mumbai India.

Specification

| Product Name | Orifice Flanges | |

| Face Finish | RF,FF,RTJ,TF,GF | |

| Size | ½” (15 NB) to 48″ (1200NB) | |

| Standard | ANSI | ANSI B16.5 ASME B16.47 series A/B |

| DIN | DIN 2631 2573 2527 2565 2641 | |

| GOST | GOST 12820-80,GOST 12821-80,Gost Blind | |

| EN | EN1092-1:2002 | |

| JIS | JIS B2220-2004, KS D3576, KS B6216,KS B1511-2007,JIS B2261; JIS B8210 | |

| BS | BS4504,BS10 Table D/E | |

| UNI | UNI 2253-67,UNI6091-67,UNI2276-67,UNI2280-67,UNI6089-67 | |

| SABS | SABS 1123 | |

| ANSI : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 ,JIS,DIN,BS4504,SABS1123,EN1092-1, UNI,AS2129,GOST-12820 DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 B.S : BS4504 , BS4504, BS1560, BS10 |

||

| Material | ANSI | CS A105/SA 105N,SS 304/304L,316/316L Alloy Steel: WHPY45/52/65/80 |

| DIN | CS RST37.2;S235JR SS 304/304L,316/316L | |

| GOST | CS CT20;16MN;SS 304/304L,316/316L | |

| EN | CS RST37.2;S235JR;C22.8SS 304/304L,316/316L | |

| JIS | CS SS400,SF440,SS 304/304L, 316/316L | |

| BS | CSRST37.2;S235JR;C22.8;Q235SS 304/304L,316/316L | |

| UNI | CSRST37.2;S235JR;C22.8;Q235SS 304/304L,316/316L | |

| SABS | CSRST37.2;S235JR;Q235;SS 304/304L,316/316L | |

| Pressure | ANSI | Class 150, 300, 600, 900, 1500 2500lbs |

| DIN | PN6,PN10,PN16,PN25,PN40,PN64,PN100 | |

| GOST | PN6,PN10,PN16,PN25 | |

| EN | PN6,PN10,PN16,PN25,PN40,PN64,PN100 | |

| JIS | 1K,2K,5K,10K,16K,20K,30K,40K | |

| BS | PN6,PN10,PN16,PN25,PN40,PN64,PN100 | |

| UNI | PN6,PN10,PN16,PN25,PN40 | |

| SABS | 600KPA,1000,1600,2500,4000 | |

| Size | ANSI | 1/2” – 60” |

| DIN | DN15-DN2000 | |

| GOST | DN10-DN1600 | |

| EN | DN15-DN2000 | |

| JIS | 15A-1500A | |

| BS | DN15-DN2000 | |

| UNI | DN10-DN2000 | |

| SABS | DN10-DN600 | |

| Coating | varnish, yellow paint, anti-rust oil, galvanizing etc | |

| Usage | Used for the connection of all kinds of pipeline | |

| to convey the water, steam, air, gas and oil | ||

| Package | Wooden cases/pallets | |

| Delivery | Within 30 days | |

| Certificate | TUV, ISO9001:2008 | |

| Stainless Steel Orifice Flanges | ASTM A182 F202, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 316LN, 310S, 317L, 321, 410, 420, 440C, 202, F904L | |

| Alloy Steel Orifice Flanges | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 | |

| Carbon Steel Orifice Flanges | ASTM / ASME A/SA 105, ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F70 | |

| Duplex Steel Orifice Flanges | ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 | |

| Standard Specifications | ANSI : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 ,JIS,DIN,BS4504,SABS1123,EN1092-1, UNI,AS2129,GOST-12820 DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 B.S : BS4504 , BS4504, BS1560, BS10 |

|

| Specialize | As per drawing | |

| Pressure Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS ASA 150, ASA 300, PN 6,10,16,25, 40,64,100,160 ETC. available with NACE MR 01-75 | |

| Flanges Forms & Types | Orifice Flanges, Weld Neck Flanges – WNRF, Socket Weld Flanges – SWRF, Slip On Raise Face – SORF, Blind Raise Face – BLRF, Spectacle Blind, Ring Joint, Large Dia Flanges, Girth Flange, Lap Joint Flanges, Screwed (Threaded) Flanges, Long Weld Neck Flanges, Reducing. | |

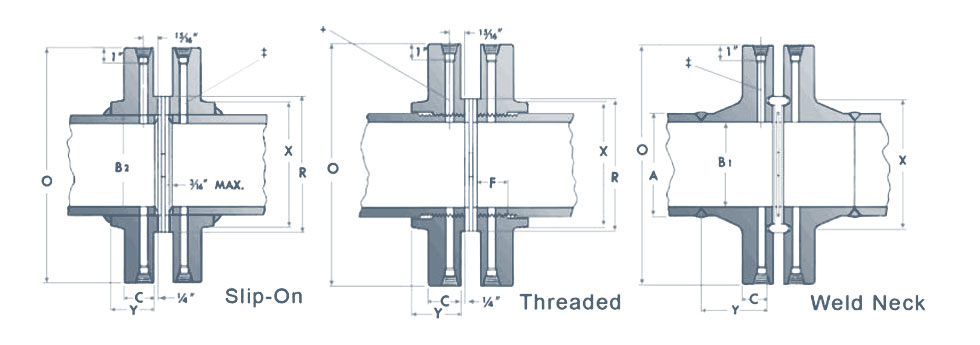

Dimension of ASME B16.5 Orifice Flanges

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Weld Neck OD | Welding Neck Length | RF Dia. | RF Height | PCD | Orifice Hole dia | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | F | G | H | I | ||||||||

| 1 | 25 | 125 | 36.6 | 54 | 33.4 | 81 | 50.8 | 2 | 88.9 | 6.4 | 4 | 5/8 | 125 | 3/4 | M16 | 4.5 |

| 1 1/2 | 40 | 155 | 36.6 | 70 | 48.3 | 84 | 73 | 2 | 114.3 | 6.4 | 4 | 3/4 | 135 | 7/8 | M20 | 6.5 |

| 2 | 50 | 165 | 36.6 | 84 | 60.3 | 84 | 92.1 | 2 | 127 | 6.4 | 8 | 5/8 | 125 | 3/4 | M16 | 7 |

| 2 1/2 | 65 | 190 | 36.6 | 100 | 73 | 87 | 104.8 | 2 | 149.2 | 6.4 | 8 | 3/4 | 135 | 7/8 | M20 | 7.5 |

| 3 | 80 | 210 | 36.6 | 117 | 88.9 | 87 | 127 | 2 | 168.3 | 9.5 | 8 | 3/4 | 135 | 7/8 | M20 | 9.4 |

| 4 | 100 | 255 | 36.6 | 146 | 114.3 | 90 | 157.2 | 2 | 200 | 12.7 | 8 | 3/4 | 135 | 7/8 | M20 | 13.2 |

| 6 | 150 | 320 | 36.6 | 206 | 168.3 | 98 | 215.9 | 2 | 269.9 | 12.7 | 12 | 3/4 | 135 | 7/8 | M20 | 14.6 |

| 8 | 200 | 380 | 39.7 | 260 | 219.1 | 110 | 269.9 | 2 | 330.2 | 12.7 | 12 | 7/8 | 145 | 1 | M24 | 30 |

| 10 | 250 | 445 | 46.1 | 321 | 273 | 116 | 323.8 | 2 | 387.3 | 12.7 | 16 | 1 | 165 | 1 1/8 | M27 | 41 |

| 12 | 300 | 520 | 49.3 | 375 | 323.8 | 129 | 381 | 2 | 450.8 | 12.7 | 16 | 1 1/8 | 180 | 1 1/4 | M30 | 62 |

| 14 | 350 | 585 | 52.4 | 425 | 355.6 | 141 | 412.8 | 2 | 514.4 | 12.7 | 20 | 1 1/8 | 185 | 1 1/4 | M30 | 84 |

| 16 | 400 | 650 | 55.6 | 483 | 406.4 | 144 | 469.9 | 2 | 571.5 | 12.7 | 20 | 1 1/4 | 195 | 1 3/8 | M33 | 111 |

| 18 | 450 | 710 | 58.8 | 533 | 457 | 157 | 533.4 | 2 | 628.6 | 12.7 | 24 | 1 1/4 | 205 | 1 3/8 | M33 | 138 |

| 20 | 500 | 775 | 62 | 587 | 508 | 160 | 584.2 | 2 | 685.8 | 12.7 | 24 | 1 1/4 | 215 | 1 3/8 | M33 | 171 |

| 24 | 600 | 915 | 68.3 | 702 | 610 | 167 | 692.2 | 2 | 812.8 | 12.7 | 24 | 1 1/2 | 240 | 1 5/8 | M39 | 247 |

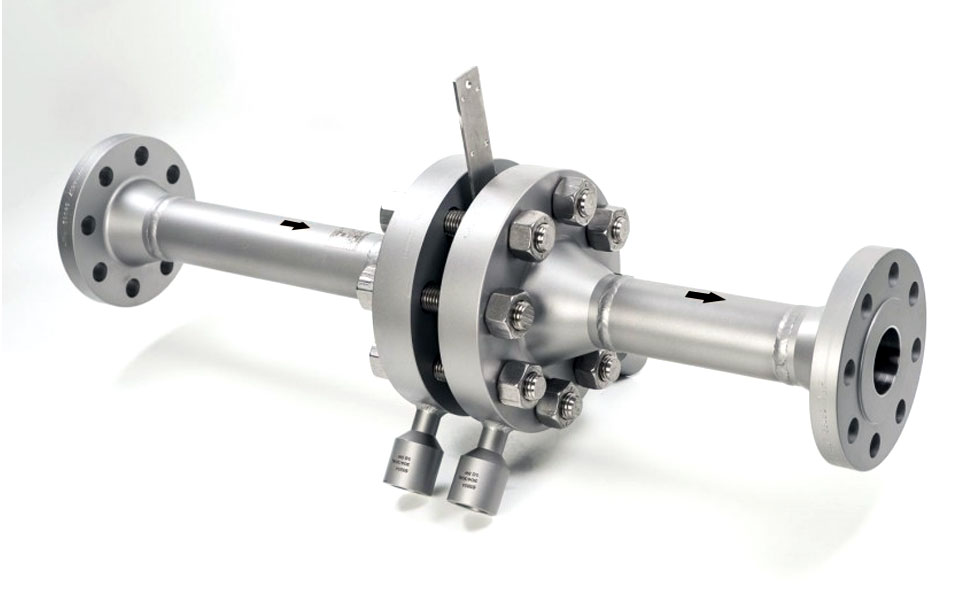

Raised Face Orifice Flanges

In raised face flanges, the gasket surface is located above the bolting line of the flange. The height of the raised surface may vary according to the flange pound rating. The purpose of a RF flange is to concentrate more pressure on a smaller gasket area and thereby increase the pressure containment capability of the joint. The Raised Face flange is the most common type used in process plant applications, and is easily to identify.

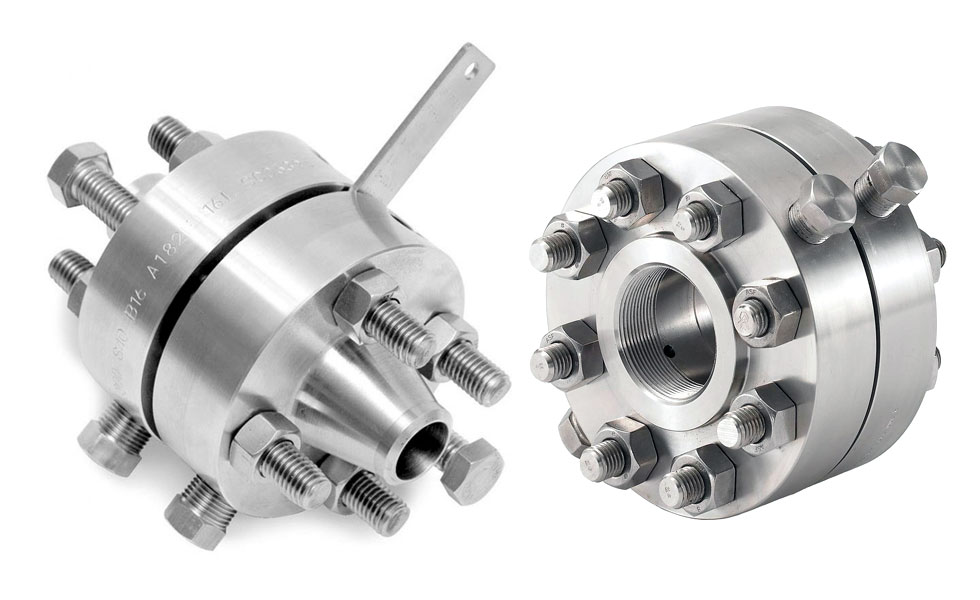

Ring Type Joint Orifice Flanges

These are the most efficient flanges in pipeline design. Ring joint flanges have a deep groove in a ring around the face. While bolting the faces, a metal ring is compressed in this groove, which ensures extremely tight, leak-proof seal on the connection. An RTJ flange may have a raised face with a ring groove machined into it. The flanges seal when tightened bolts compress the gasket between the flanges into the grooves, deforming (or Coining) the gasket to make intimate contact inside the grooves, creating a metal to metal seal.

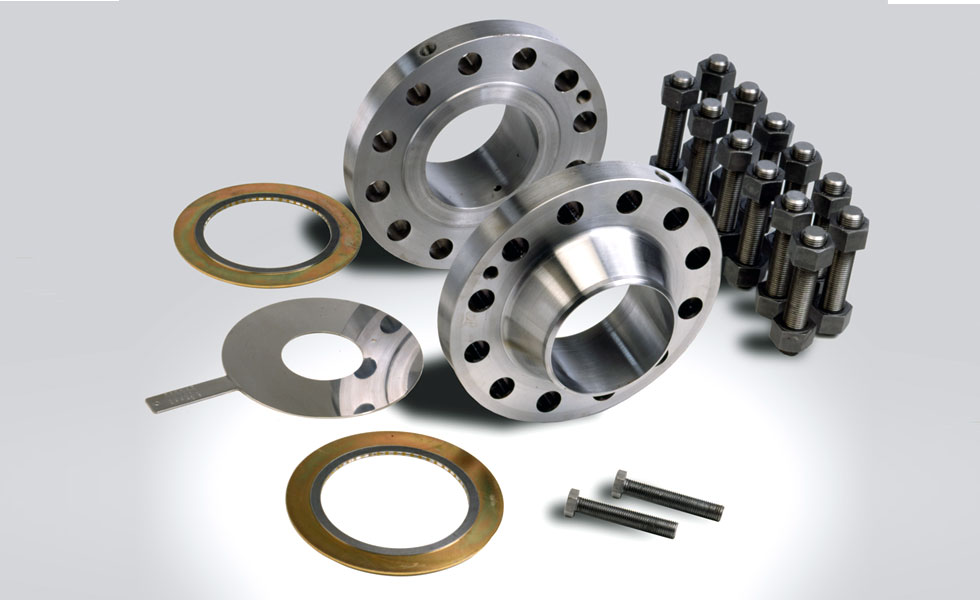

Orifice Flanges Plates

As the name implies, it consists of an Orifice Plate which is the basic element of the instrument. When this Orifice Plate is placed in a line, a differential pressure is developed across the Orifice Plate. This pressure drop is linear and is in direct proportion to the flow-rate of the liquid or gas. Since there is a drop in pressure, just like Turbine Flow meter, hence it is used where a drop in pressure or head loss is permissible.

Manufacturing Materials of ASME B16.5 Orifice Flanges

| Dimensions | Base Material | Pressure Rating |

|---|---|---|

| ASME B16.5 | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| API 605 | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| ASME B16.47series A & B | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| EN1092-1 | ASTM A182 (Forgings) | PN2.5. PN6. PN10. PN16. PN25. PN40. PN63. PN100. PN160. PN250. PN320. PN400. |

| BS4504 | BS970 (Bar)ASTM A240 (Plate) ASTM A182 (Forgings) | PN2.5. PN6. PN10. PN16. PN25. PN40. PN63. PN100. PN160. |

| BS10 | BS970 (Bar)ASTM A240 (Plate) ASTM A182 (Forgings) | Table D. Table E. Table F. Table H. Table J. Table K. Table R. Table S.Table T. |

Types of Welding Neck Flanges

| A182 Gr F1 Orifice Weld Neck Flange | A182 Gr F9 Orifice Plate Flange | A182 Gr F304 Socket Weld Orifice Flange |

| A182 Gr F12 Orifice Blind Flange | A182 Gr F5 Threaded Orifice Flange | A182 Gr F316 Orifice Plate Flange |

| A182 Gr F22 Orifice Flange | A350 Gr LF2 Weld Neck Orifice Flange | A182 Gr F321 Weld Neck Orifice Flanges |

| A182 Gr F304L Orifice Weld Neck Flange | A182 Gr F316L Orifice Blind Flange | ASTM B564 Threaded Orifice Flange |

| ASTM b381 grade f2 Threaded Orifice F Dealer | ASTM b381 f5 Orifice Blind Flange Exporter | ASTM b564 uns n06600 Weld Neck Orifice Flange |

| ASTM b564 uns n06625 Socket Weld Orifice Flange | ANSI 150 Socket weld Flange Distributors | ASTM b381 f12 Orifice Plate Flang |

| Class 600 Orifice Flanges | High Quality Class 900 Orifice FlangesManufacturer | Class 1500 Orifice Flanges Stockist |

| Class 2500 Orifice Flanges Stockiest | ASTM b564 uns n06625 Socket Weld Orifice Flange | ASTM b564 uns n10665 Threaded Orifice Flange |