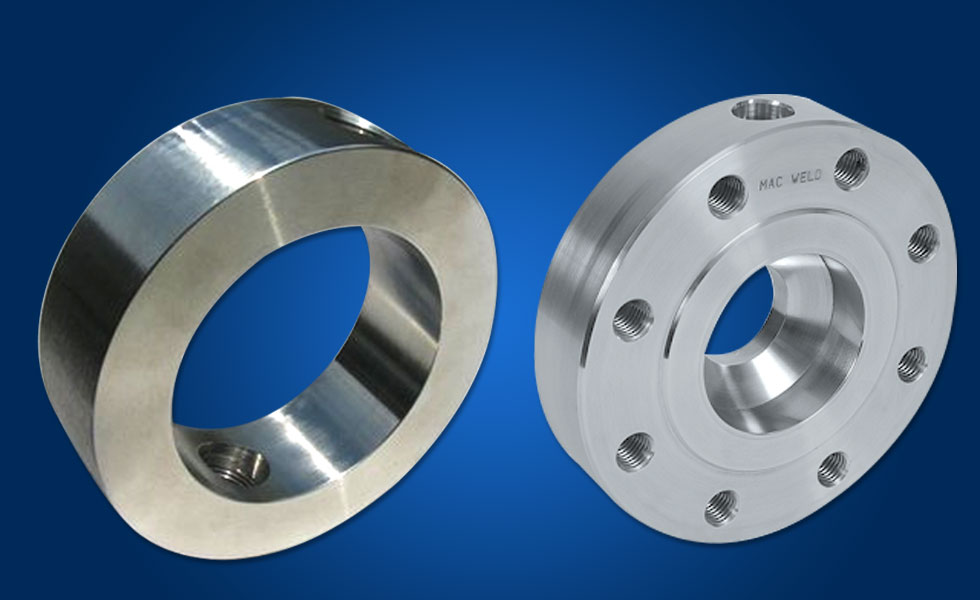

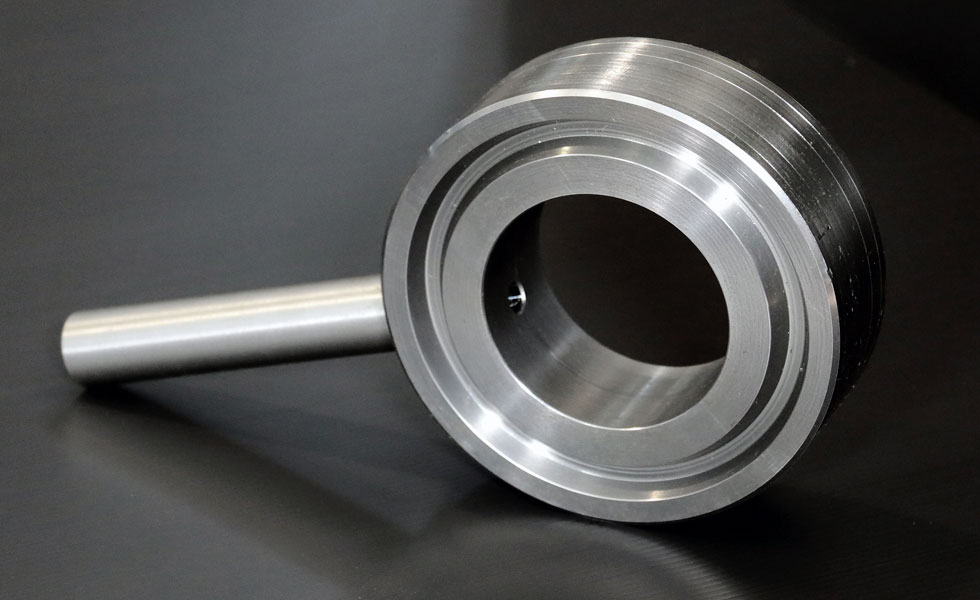

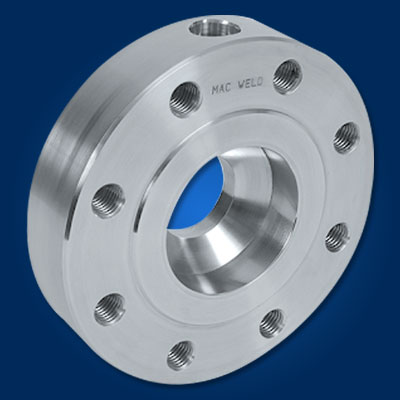

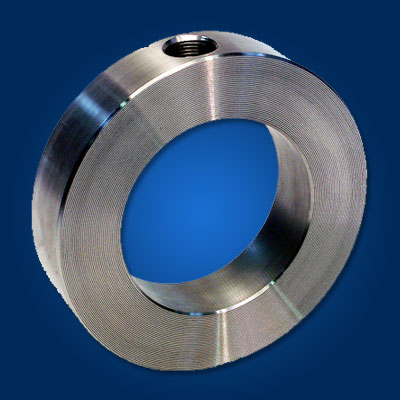

ANSI/ASME Bleed Ring & Drip Ring Flanges

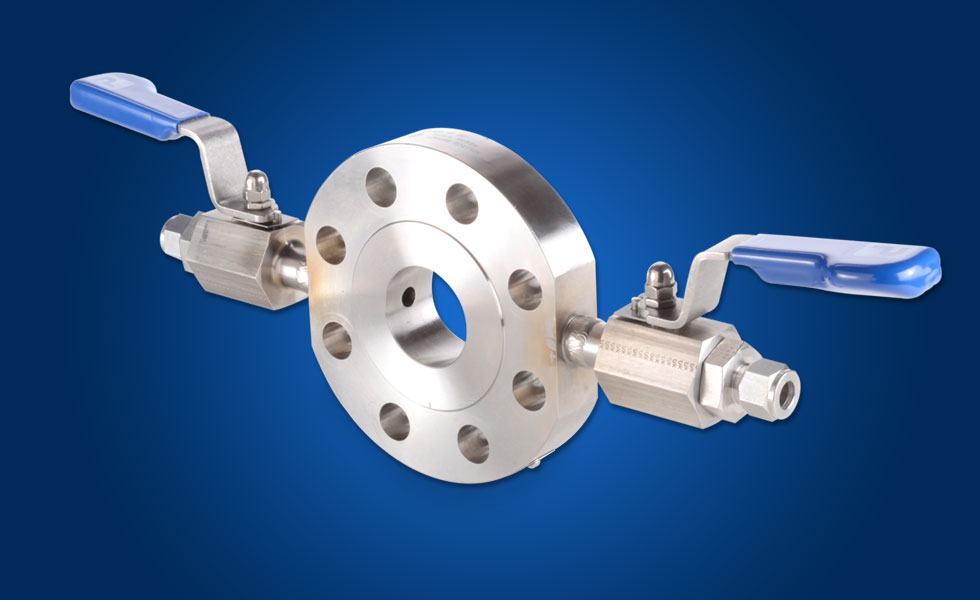

Manufacturers and Suppliers of Bleed Ring & Drip Ring Flanges in Various types of Material Grades. Suppliers of Bleed Rings, Stainless Steel Drip Ring, Steel Bleed Ring, SS Diaphragm Seal Flushing Ring, Duplex Steel Drip Ring With Plug Exporter, Nickel Concentric Bleed Ring, Monel Flanged Drip Ring Manufacturer in India.

Werner Flanges Inc. is a known distributing unit of ANSI / ASME Bleed Ring & Drip Ring Flanges, which resists attack by phosphoric, sulphuric, and mild organic acids. ANSI Stainless Steel Drip Ring contains small but important additions of iron and manganese to enhance overall strength corrosion resistance. ASME Stainless Steel Bleed Ring with additions of manganese are important in electrical engineering, where the hot strength of copper increases with only a small addition of nickel. We present our collection of specially designed ANSI SS Diaphragm Seal Flushing Ring to provide efficient solutions for different industrial requirements.

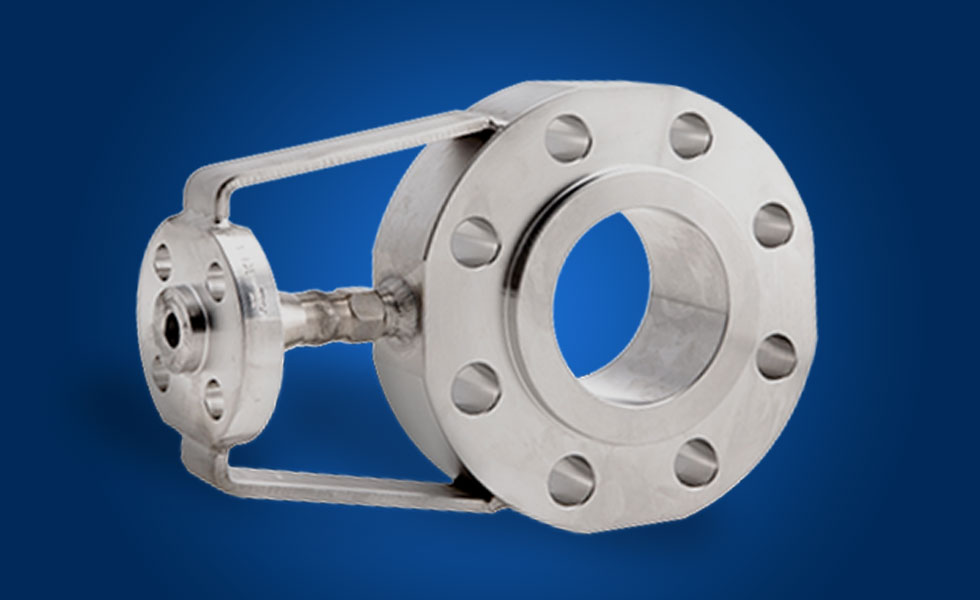

Product applications of ASME Nickel Concentric Bleed Ring include condenser tubes and plates, distiller tubes, tube sheets for condensers and heat exchangers. We are a known ANSI Duplex Steel Drip Ring With Plug Exporter, which is used in applications such as evaporator and heat exchanger tubes, salt water piping, water boxes, ship hulls and hot water tanks. As with ASME Inconel Alloy Bleed Ring, it is necessary to distinguish between wrought alloys, which are processed to semi – finished products, and cast alloys, from which castings are produced by various casting processes.

As a known ANSI Monel Flanged Drip Ring Manufacturer in India, these are designed for specialized electrical and electronic applications, which further has a very low temperature coefficient of resistance and medium-range electrical resistivity.

Werner Flanges Inc. one of the most Reliable and Certified Stockists, Manufacturers, and Exporters of ASME B16.47/ANSI B16.5 Bleed Ring, Drip Ring Flanges, MSS SP-44 Bleed Ring Flange, DIN 86029 PN10 Bleed Ring Flange, Series A & B Drip Ring Flanges.

Specification

| Bleed Ring Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

|---|---|

| ASME B16.5 Bleed Ring Flange Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Bleed Ring Flange Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Bleed Ring Flange |

| Bleed Ring Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Bleed Ring Flange |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar Bleed Ring Flange |

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Bleed Ring Flange |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Bleed Ring Flange |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar Bleed Ring Flange |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Most common types of Bleed Ring Flange | Forged / Threaded / Screwed / Plate |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Production technique |

|

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Special design | As per your drawing

AS, ANSI, BS, DIN and JIS |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Bleed Ring Flange Uses & application |

|

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. Bleed Ring Flange: -BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange

|

| Export to | Saudi Arabia, Peru, Egypt, Indonesia, Brazil, Spain, USA, Canada, Ukraine, Singapore, Thailand, Oman, Ireland, Korea, Iran, India, Dubai |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

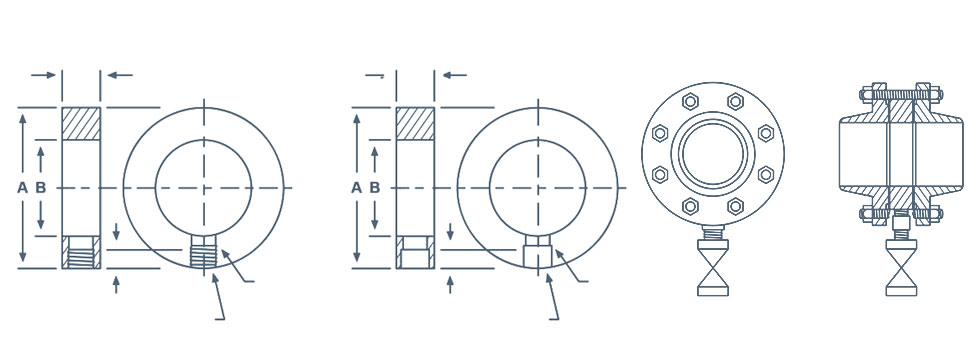

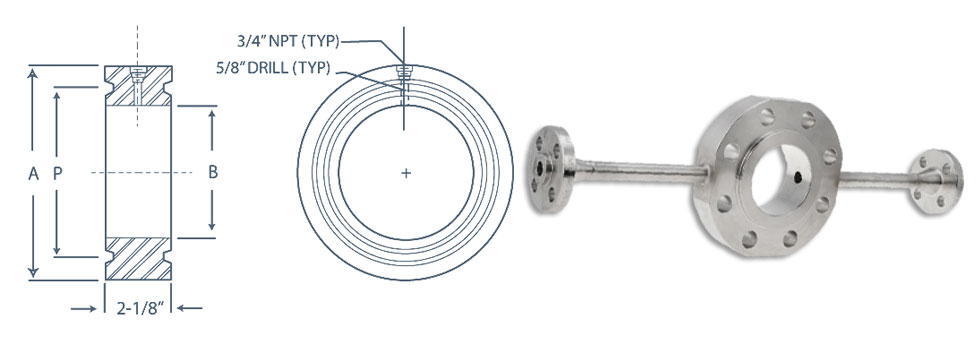

Dimensions of Bleed Ring Flanges

| Line Size | O.D. | I.D. | |||||

|---|---|---|---|---|---|---|---|

| 150# | 300# | 600# | 900# | 1500# | 2500# | ||

| 1/2 | 1 3/4 | 2 | 2 | 2 3/8 | 2 3/8 | 2 5/8 | 5/8 |

| 3/4 | 2 1/8 | 2 1/2 | 2 1/2 | 2 5/8 | 2 5/8 | 2 7/8 | 7/8 |

| 1 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 1/8 | 3 3/8 | 1 1/8 |

| 1 1/2 | 3 1/4 | 3 5/8 | 3 5/8 | 3 3/4 | 3 7/8 | 4 5/8 | 1 5/8 |

| 2 | 4 | 4 1/4 | 4 1/4 | 5 1/2 | 5 5/8 | 5 3/4 | 2 1/8 |

| 2 1/2 | 4 3/4 | 5 | 5 | 6 3/8 | 6 1/2 | 6 5/8 | 2 1/2 |

| 3 | 5 1/4 | 5 3/4 | 5 3/4 | 6 1/2 | 6 7/8 | 7 3/4 | 3 1/8 |

| 4 | 6 3/4 | 7 | 7 1/2 | 8 | 8 1/4 | 9 1/4 | 4 1/8 |

| 6 | 8 5/8 | 9 3/4 | 10 3/8 | 11 1/4 | 11 1/8 | 12 1/8 | 6 1/8 |

| 8 | 10 7/8 | 12 | 12 1/2 | 14 | 13 7/8 | 15 1/4 | 8 |

| 10 | 13 1/4 | 14 1/8 | 15 5/8 | 17 | 17 1/8 | 18 3/4 | 10 1/8 |

| 12 | 16 | 16 1/2 | 17 3/4 | 19 3/8 | 20 1/2 | 21 5/8 | 12 |

| 14 | 17 5/8 | 19 | 19 1/8 | 20 1/4 | 22 1/2 | – | 14 |

Dimensions Tolerance of Bleed Ring Flanges

| Outside Diameter: ≤ 24 = 1.6 mm | > 24 = ± 3.2 mm |

Inside Diameter: not applicable |

| Diameter of Contact Face: 1.6 mm Raised Face = ± 0.8 mm6.35 mm Raised Face, Tongue & Groove / Male-Female = ± 0.4 mm |

Outside Diameter of Hub: ≤ 12 = + 2.4 mm / – 1.6 mm | ≥ 14 = ± 3.2 mm |

| Diameter of Counterbore: not applicable |

Drilling: Bolt Circle = 1.6 mm | Bolt Hole Spacing = ± 0.8 mmEccentricity of Bolt Circle with Respect to Facing≤ 2½ = 0.8 mm max. | ≥ 3 = 1.6 mm max. |

| Thickness: ≤ 18 = + 3.2 mm / – 0 | ≥ 20 = + 4.8 mm / – 0 |

Length thru Hub: ≤ 18 = + 3.2 mm / – 0.8 mm | ≥ 20 = + 4.8 mm / – 1.6 mm |

RTJ Bleed Ring Flanges Dimensions

| Line Size | DIMENSIONAL DATA | |||||||||||

| 300# / 400# / 600# | 900# | 1500# | 2500# | |||||||||

| A | B | RING | A | B | RING | A | B | RING | A | B | RING | |

| 1″ | 2.750 | 1.320 | R-16 | 2.812 | 1.320 | R-16 | 2.812 | 1.320 | R-16 | 3.250 | 1.320 | R-18 |

| 1-1/2″ | 3.562 | 1.900 | R-20 | 3.625 | 1.900 | R-20 | 3.625 | 1.900 | R-20 | 4.500 | 1.900 | R-23 |

| 2″ | 4.250 | 2.375 | R-23 | 4.875 | 2.375 | R-24 | 4.875 | 2.375 | R-24 | 5.250 | 2.375 | R-26 |

| 2-1/2″ | 5.000 | 2.875 | R-26 | 5.375 | 2.875 | R-27 | 5.375 | 2.875 | R-27 | 5.875 | 2.875 | R-28 |

| 3″ | 5.750 | 3.500 | R-31 | 6.125 | 3.500 | R-31 | 6.625 | 3.500 | R-35 | 6.625 | 3.500 | R-32 |

| 4″ | 6.875 | 4.500 | R-37 | 7.125 | 4.500 | R-37 | 7.625 | 4.500 | R-39 | 8.000 | 4.500 | R-38 |

| 6″ | 9.500 | 6.625 | R-45 | 9.500 | 6.625 | R-45 | 9.750 | 6.625 | R-46 | 11.000 | 6.625 | R-47 |

| 8″ | 11.875 | 8.625 | R-49 | 12.125 | 8.625 | R-49 | 12.500 | 8.625 | R-50 | 13.375 | 8.625 | R-51 |

| 10″ | 14.000 | 10.750 | R-53 | 14.250 | 10.750 | R-53 | 14.625 | 10.750 | R-54 | 16.750 | 10.750 | R-55 |

| 12″ | 16.250 | 12.750 | R-57 | 16.500 | 12.750 | R-57 | 17.250 | 12.750 | R-58 | 19.500 | 12.750 | R-60 |

Types of Bleed Ring & Drip Ring Flanges

| ASME B16.20 Drip Rings | 2 150# Bleed ring | ASME B16.50 Drip Rings |

| 2 Bleed Rings | Raised Face Bleed Rings | Stainless Steel Bleed Ring Suppliers |

| Raised Face Bleed Ring Suppliers | Steel Bleed Ring | Raised Face Bleed Rings Distributors |

| ANSI B16.20 class 150 Bleed Ring Stockholder | ANSI B16.5 Class 150 Bleed Ring | ASTM A182 Stainless Steel Bleed Ring |

| ASME B31.3 Bleed Rings | Bleed Ring Dimensions | High Nickel Alloy Bleed Ring |

| Bleed Ring Class 150 | Pipe Bleed Ring | Hastelloy Flat Faced Bleed Ring Stockist |

| ANSI B16.5 Bleed Ring | Bleed Rings in ASME B31.3 | ANSI B16.50 class 150 Bleed Ring Stockholder |

| Bleed Ring Flat Face | Vent Rings | ANSI B16.50 Class 150 Bleed Ring |

| 4 Bleed Ring | High Quality Bleed Ring | ANSI B16.50 Bleed Ring |

| Bleed Rings in ASME B31.3 Exporters | Pipe Bleed Ring | 4 Bleed Ring |